In the packaging industry, laminating technology has become one of the core processes for valve bag production due to its unique performance and cost advantages.

Product name :

Valve pocket bag making machine core technologyItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsValve pocket bag making machine core technology

In the packaging industry, laminating technology has become one of the core processes for valve bag production due to its unique performance and cost advantages. As a benchmark in industry technology, automatic polypropylene sacks manufacturer Gachn Group's valve bag making machine has become the world's only intelligent equipment that can efficiently mass-produce single-sided laminating valve bags with full servo control, precise temperature control system and highly automated design, helping companies achieve both quality and efficiency improvements.

Why choose single-sided laminating valve bags?

Cost optimization: Single-sided laminating reduces the weight of the laminating film, and the cost of raw materials drops by 15%~20%, which is especially suitable for the economical packaging needs of heavy and fragile products.

Quality upgrade: The laminating layer is smooth and delicate, the bag body feels soft and flexible, and the printed pattern is clearer, which significantly improves the appearance of the product.

Environmental protection and energy saving: Reduce material use and energy consumption, in line with the trend of green production, and reduce the annual carbon emissions of a single machine by more than 10%.

Sealing protection: The laminating surface accurately covers the bag body, isolates water vapor and pollutants, and ensures the long-term stability of the internal materials.

Automatic bopp laminated pp woven bags manufacturer's single-sided laminating technology gives valve bags excellent texture and durability

The core technical advantages of Gachn 's bag making machine

1. Full servo drive, precise control of production

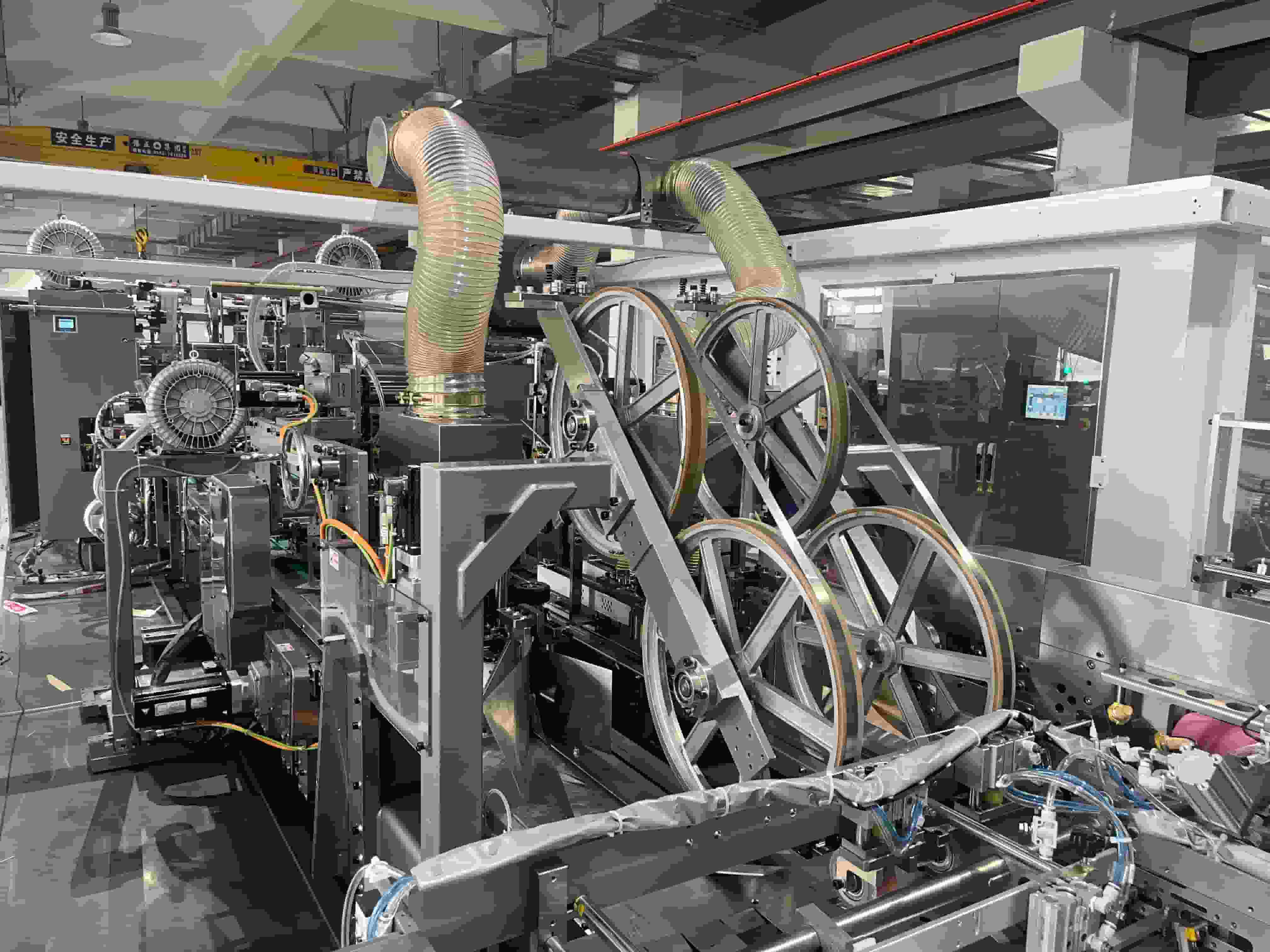

Adopting a multi-axis synchronous servo system (as shown in the figure), the positioning accuracy is ±0.1mm, supporting one-click switching of bag type and size, and adapting to diversified order requirements.

The intelligent HMI interface monitors production parameters in real time, and the operator can quickly adjust key indicators such as laminating speed and tension, increasing production efficiency by 30%.

Intuitive human-machine interface to achieve millisecond-level response of production parameters

2. Ultra-high temperature dynamic temperature control system

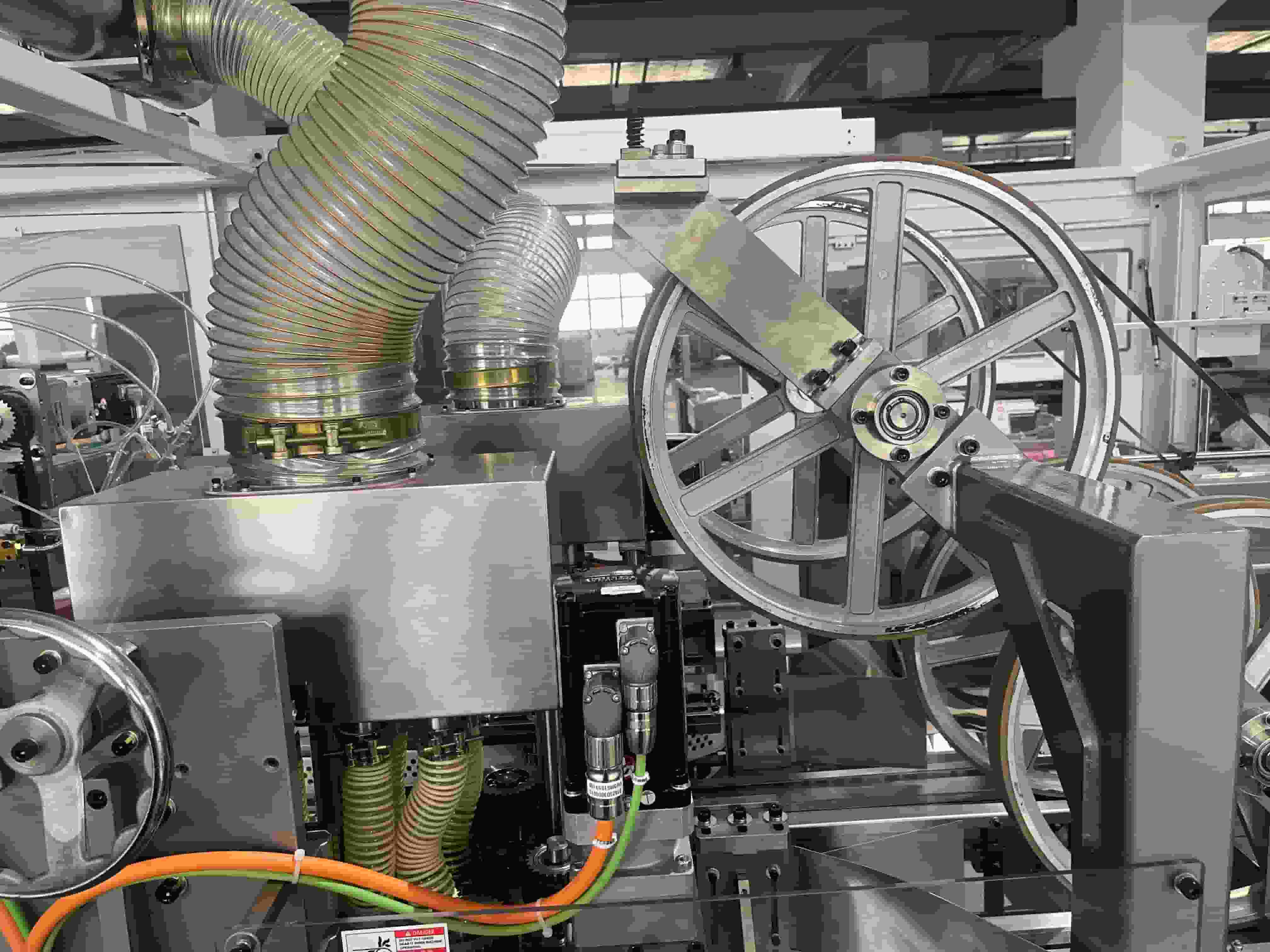

Patented heating air gun: heats up to 300℃ within 3 seconds, with real-time monitoring by thermocouple, temperature fluctuation ≤±1℃, ensuring uniform laminating bonding strength.

Adaptive algorithm: automatically adjusts heating power according to material thickness to avoid overheating and damage to the bag body, and reduces the scrap rate to less than 0.5%. Precise temperature control technology ensures zero defects in lamination welding

3. High stability unwinding mechanism

Magnetic powder brake + servo traction dual drive design, unwinding tension fluctuation <2%, completely solve the problem of lamination surface deviation.

Supports continuous production of 1000kg-class large-diameter materials, roll change downtime is shortened to 5 minutes, and the equipment single-time overall efficiency (OEE) is 5 minutes faster than European brands.

Creating multi-dimensional value for customers

Cost reduction and efficiency improvement

The single-sided lamination process saves raw material costs, combined with the 24-hour continuous production capacity of Gachn equipment, the comprehensive production capacity is increased by 40%.

Modular design supports rapid maintenance, the life of key components is extended by 50%, and the annual maintenance cost is reduced by 30%.

Flexible adaptation

Can customize the production of various bag types (square bottom, seam bottom, hand-held, etc.), compatible with PE, PP, composite film and other materials, to meet the needs of multiple industries such as food, chemical, and building materials.

Green Smart Manufacturing

Integrated heat recovery system reduces production energy consumption by 25%; supports environmentally friendly water-based adhesive processes to help companies pass ISO 14001 certification.

Industry application scenarios

Building materials industry: produces weather-resistant coated bags, suitable for heavy powder packaging such as cement and gypsum powder, with a bag breakage rate of <0.1%.

Food industry: Meets FDA standard coating materials to ensure moisture and bacteria proofing requirements for products such as rice, flour, and feed.

Chemical industry: Antistatic coating layer design for safe packaging of dangerous goods such as dyes and granular resins.

Choose Gachn to start a new era of intelligent packaging

Valve bag bag making machine developed by automatic laminated pp woven bag manufacturer Gachn focuses on leading technology, stable and efficient, green and low-carbon, and provides customers with a full chain of services from equipment delivery to process optimization. Now launching a limited-time service package: