The AI detection technology independently developed by Gachn Group is the world's first-class latest technology for PP woven block bottom vavle sack making machine.

Product name :

The world's leading technology of valve pocket bag making machineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsThe world's leading technology of valve bag making machine

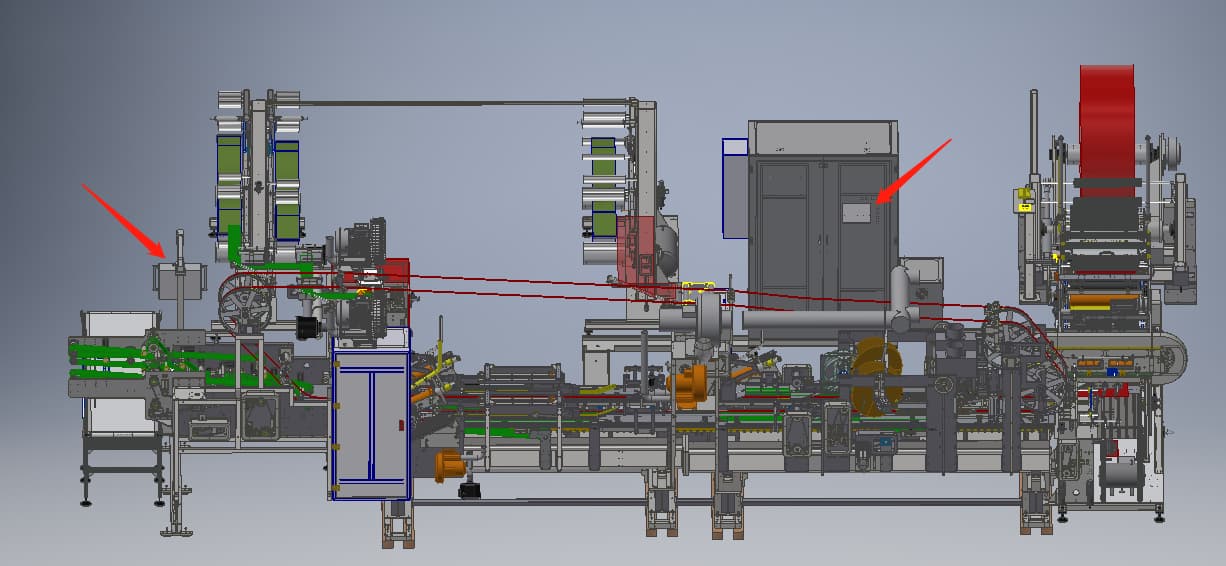

pp woven block bottom valve bag making machine FK008-II is an ideal line of equipment to produce block bottom plastic valve sacks. Weighing 17 tons, the valve sack making machine is a product of our company’s independent research and development as well as a collection of our core technologies and patent inventions. The bag making mechanism is extensively applied in chemical, construction, manufacturing and other industries.

Comparison with international old brands

VS

VS

The relationship between GACHN and international old brands

Starlinger, W&H, these two companies are the pioneers of the starlinger Valve bottomer bag CONVERTEX and W&H CONVERTEX valve sack converting machine (bsw), Gachn respects them and they have something worth learning from us.

Our machine benchmarking CONVERSION LINE ad*starKON Sxneo and W&H's CONVERTEX CL 140 (bsw).

Note: If you need faster speed, we can provide customized service. Our machines are controlled by more than 30 servos, the minimum speed can be adjusted to 60bags/min, the highest speed can be adjusted to 160bags/min. In actual production, bag quality is the most important, not the pursuit of speed.

The advantages of GACHN

Although the listing time of GACHN is not longer than that of Starlinger and W&H, it is undeniable that GACHN's experience and technology are excellent. Our new China was founded relatively late. When the People's Republic of China was founded, it was backward in all aspects, but we soon developed two bombs and one star, nuclear weapons, and China now has advanced technology for landing on the moon. The Chinese people are fully aware of the truth that backward people will be beaten, and we are racing against time to catch up with the development of the world. Some people joke that there are three evolutionary miracles in Asia: the Japanese don't eat, the Koreans don't sleep, and the Chinese don't rest. We Chinese stay at our posts. The mission of Gachn is to decode key technologies and create value for customers.Gachn have the technical strength and experience.

Comparison between Gachn valve bag making machine and old international brands

Our business philosophy is innovation-driven capital development and win-win cooperation for the future.

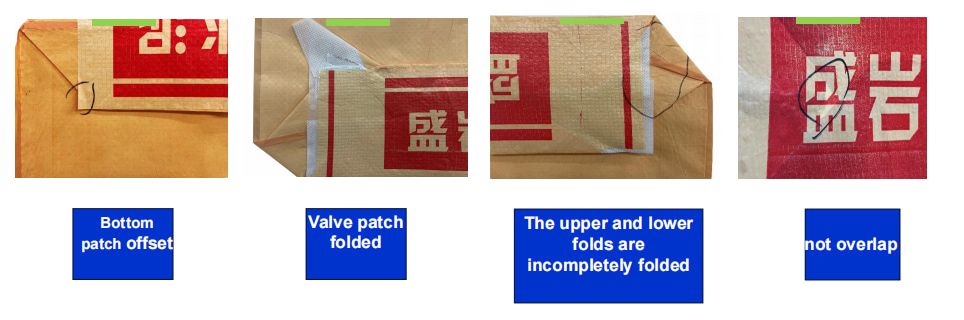

1.Our new technology - The AI visual inspection equipment

The visual inspection equipment is mainly composed of inspection system and mechanical system, which can detect various defects of the front and back of the incoming coil materials in real time and take photos of the finished products in the process of bag making. The signal provided by the encoder is collected online in real time, and the pictures obtained by the camera are analyzed and output a test result through the detection software algorithm of the industrial control computer. And NG bad unified shutdown alarm, data statistics and so on.

The main interface of AI visual inspection is an important interface for users to interact and operate with the computer. Through the operation bar, function bar, status bar, production information input area, process detection data display area, alarm log, real-time image display area, users can easily access and manage the indicators of visual detection to complete a variety of elimination tasks.

Missed removal rate = missed removal Quantity *100%

Quantity of bag produced

◆ The Al visual inspection equipment of the collecting valve sack takes the appearance characteristics of the front and back of the received coil material of the valve bag, the finished bag valve sticker and the bottom sticker through CCD images;

◆ The visual inspection image processing system will convert the information of pixel distribution, brightness and color into digital signals and perform splicing operation on the valve pocket;

◆ Al drives model learning, identifies the results, alerts the NG bag body, executes the next culling instruction, synchronously stores images, summarizes statistical data, and so on.

2.Comparison of machine performance with European equipment

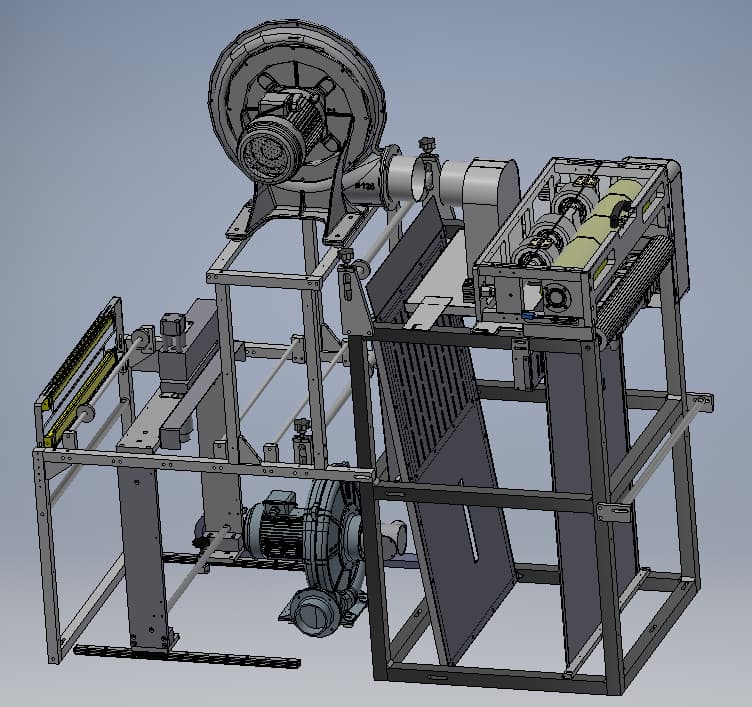

Fabric feeding Devive

VS

VS

Our equipment European equipment

Our valve bag making machine equipment uses a hydraulic automatic unwinding mechanism and a pneumatic braking device. One person can easily unwinding and winding Fabric rolls. It is equipped with photoelectric roll diameter measurement to monitor the roll diameter in real time. With the automatic tension mechanism and automatic correction system, it can ensure The smoothness of the fabric roll. Internationally renowned brand equipment does not have a material storage mechanism, and the fabric roll material is relatively loose.

U shape unwinding mechanism

VS

VS

Our equipment European equipment

Our equipment adopts a low tension conveying system, which can achieve stable and reliable high-speed unwinding conveying of substrate. Realization principle: By pre-storing the base fabric, the traction motor of the cutting mechanism can realize the constant force of dragging the base fabric at different speeds, and does not produce the phenomenon of slipping so as to avoid the length of cutting cloth. The internationally renowned brand equipment uses the swing arm mechanism, the tension is large, easy to cause the feeding length error.

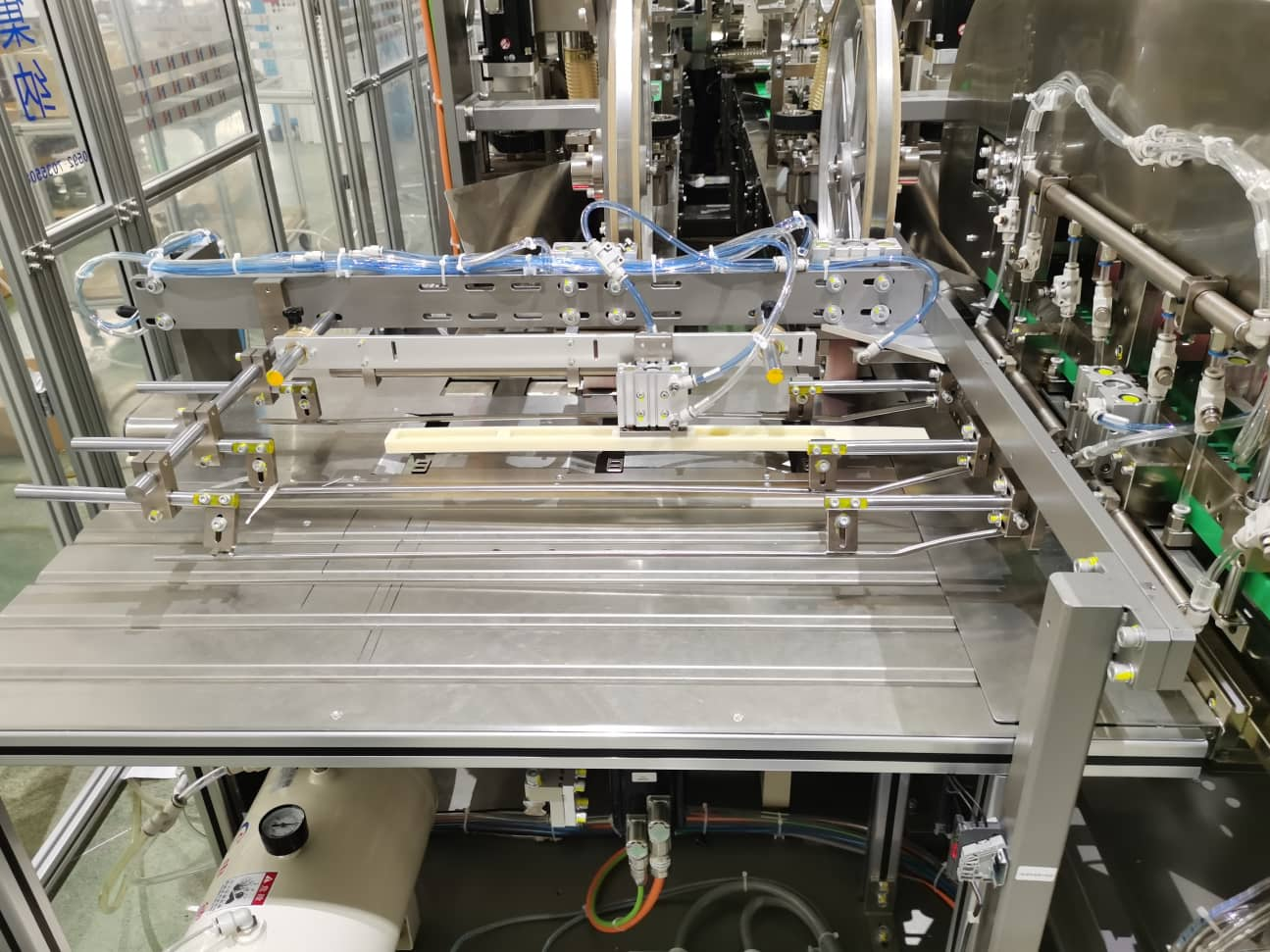

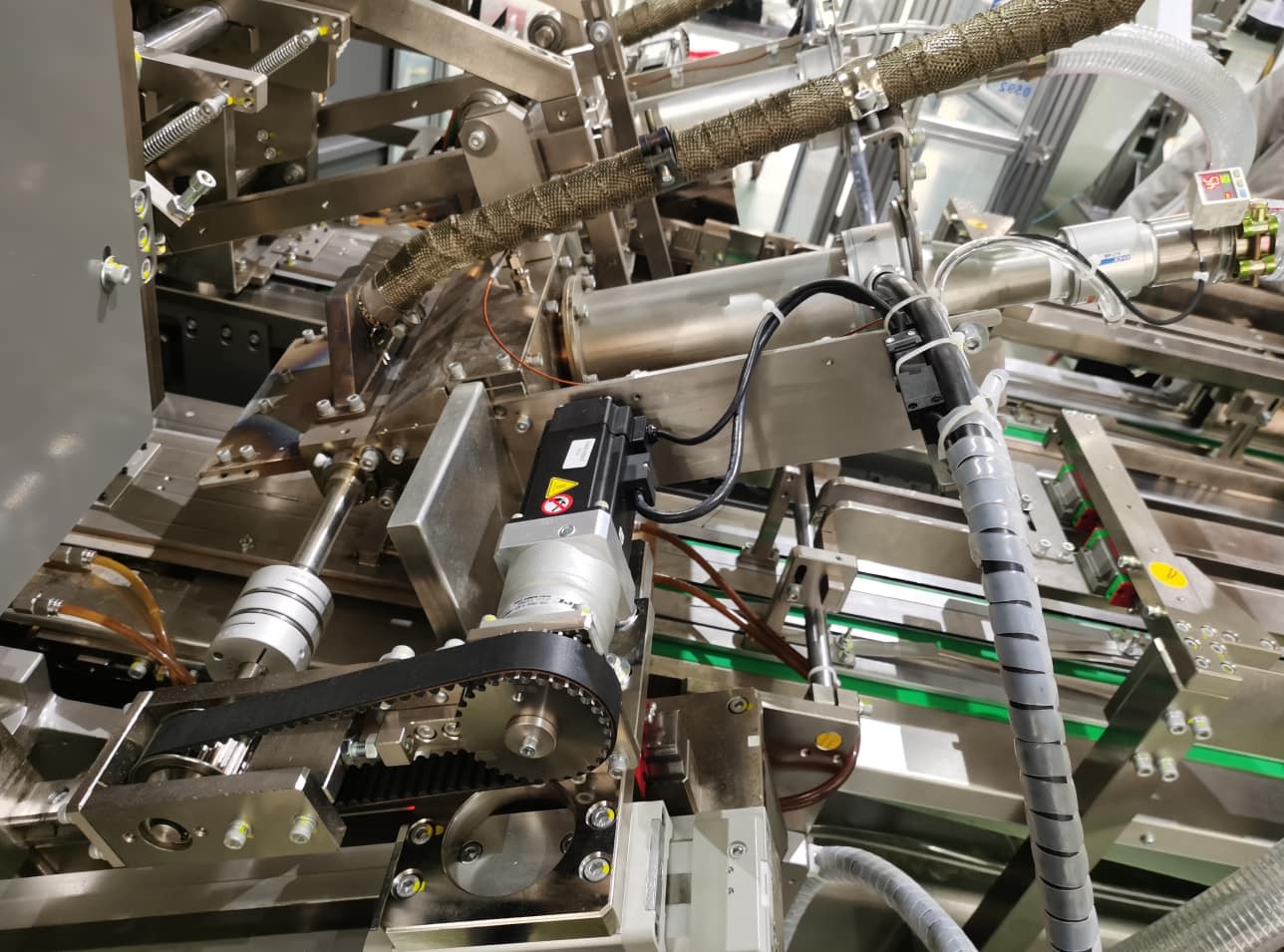

Bag Making transfer mechanism

VS

VS

Our equipment European equipment

The traction and transfer mechanism of our equipment adopts the bag body steering mechanism controlled by the vacuum system, which realizes the high-speed transfer of the bag body in the vertical movement direction and is fast and stable.The FK008-II bag making machine is our Independent research and development ,with independent core technology and intellectual property rights,there is no litigation risk of infringement of intellectual property rights.

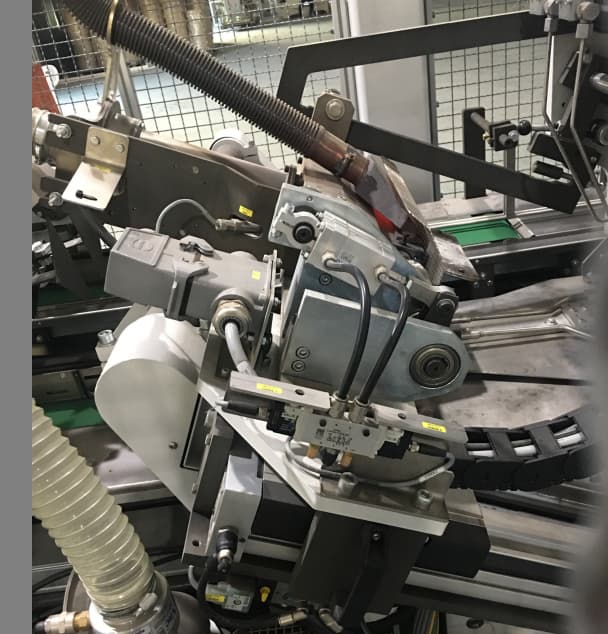

Bag opening mechanism

VS

VS

Our equipment European equipment

The bag opening mechanism used in our equipment is the company's unique patent, using an innovative bag opening process, the use of negative pressure and the multi-step combination of the conveying system, to achieve high efficiency, stability, low maintenance, to help customers get the maximum value. Independent research and development, with independent core technology and intellectual property rights, no litigation risk of infringement of intellectual property rights. The internationally renowned brand equipment is the suction cup opening bag, the suction cup life is short, need to be replaced frequently; The mechanism adopts reciprocating movement mode. Under the condition of high speed movement, the mechanism has jitters and other uneasiness factors, which is easy to cause the failure of opening the bag.

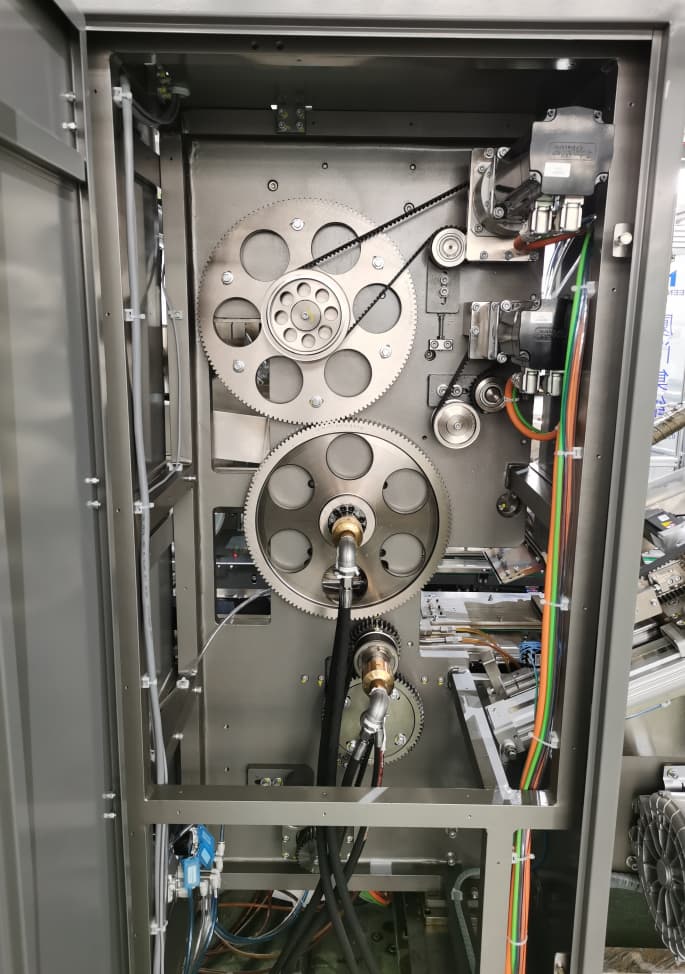

3 sets of Heat sealing mechanism

VS

VS

Our equipment European equipment

Our equipment adopts professionally designed heat sealing welding system, using unique technology to achieve uniform wind and constant size. Servo control of the wind commutator axis switching, precise control of welding on and off time, welding quality is higher. The width of the mouthpiece is adjustable, and the welding width can be controlled flexibly. The cylinder mechanism is used in internationally renowned brand equipment to control the blowing switching action. The movement time of the cylinder is easily affected by factors such as the sticking caused by the wear of spare parts and the change of the air pressure of the air compressor, thus affecting the welding position. The width of the mouthpiece is adjusted by replacing the width block, each 5mm is a unit, and the replacement and size adjustment are not flexible.

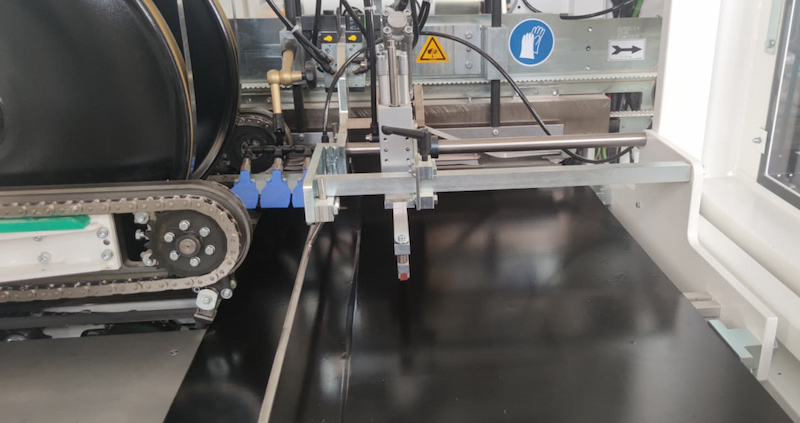

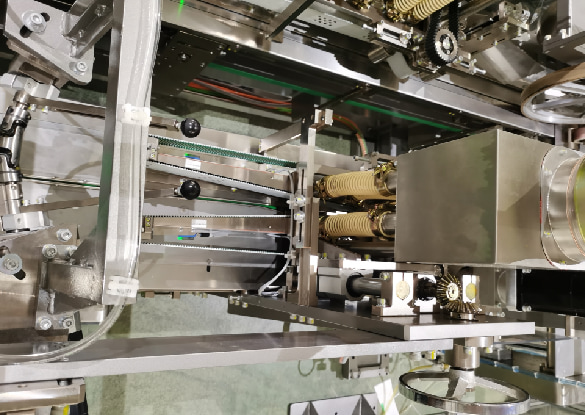

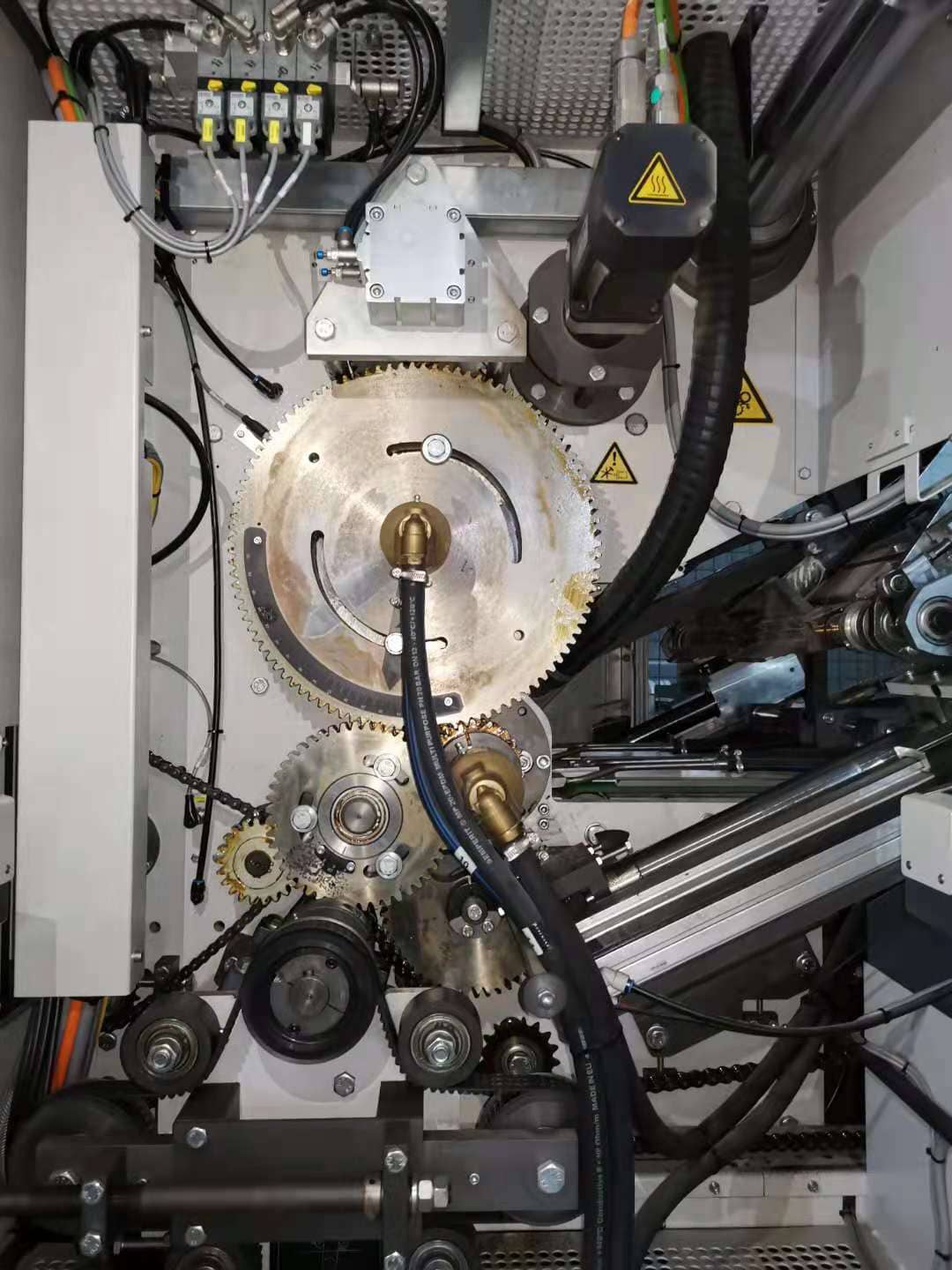

3 sets of heat-seald knife roller and adsorption roller mechanisms

VS

VS

Our equipment European equipment

The 3 sets of heat-sealed knife roller and adsorption roller mechanisms on our equipment are all independently controlled by servo motors, and the file number of corresponding parameters is directly transferred when the number is changed to achieve rapid number change. The position before and after welding of valve paste and bottom paste material can be manually adjusted online; Foreign equipment adopts the working mode of mechanical gear linkage. When replacing specifications, it is necessary to loosen the screws on the gear, adjust the Angle, which is inconvenient to operate and troublesome to change the number and adjust.

Remote linkage of the operation screen

VS

VS

Our equipment European equipment

We use dual screen interaction on the equipment, so that the operation is more convenient, the data monitoring system combined with cloud control technology, to achieve data collection, equipment remote diagnosis, so that efficient production and convenient maintenance is possible. Internationally renowned brand equipment only one screen operation trouble, can not achieve remote diagnosis and modification program, and touch screen translation text is difficult to understand.

Make the smart choice to secure the future prosperity of your business. Contact us today to learn more about how our innovative solutions can help you achieve your production goals. ↓ ↓ ↓ We are the valve sack making machine Manufacturing companies.