Gachn Jeenar manufacturing pp woven valve sack production line is already very mature and excellent,The stability and advancement of the machine make it highly competitive among its peers worldwide.

Item No :

KF008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance paid before shipmentProduct Origin :

XIAMEN,CHINAShipping Port :

XIAMEN or Or according to your needsLead Time :

3 MonthsPresenting the 50kg Cement bag Making Machine

Welcome to the world of inventive and game-changing innovation. Our state-of-the-art cement bag making machine is the extreme arrangement for assembly the taking off request for cement bags within the quickly extending African economy. Outlined particularly for creating high-quality PP woven valve sacks, our machine sets unused guidelines in proficiency, unwavering quality, and efficiency. With an noteworthy portfolio of 16 patants, we offer a risk-free venture opportunity that guarantees considerable returns.

< < < Click here to read our all patents.

Unleash the Potential of the African Cement Advertise

Africa is seeing an phenomenal financial boom, and the request for cement is skyrocketing. As development ventures and framework advancement surge over the landmass, cement packs have ended up an vital product. Our pp valve bag production line positions you at the cutting edge of this profitable showcase, permitting you to capitalize on the ever-increasing request for inventive bundling arrangements.

Unparalleled Highlights for Unmatched Execution

Ourpp woven valve sack production line gloats a extend of groundbreaking highlights that guarantee predominant execution and unrivaled efficiency. Prepared with cutting-edge innovation and exactness designing, it revolutionizes the cement sack manufacturing process, empowering you to attain momentous effectiveness picks up and fetched reserve funds.

The unique patented trangle bag opening technology designed by our company's professional technical team.The innovative bag opening process with high forming speed and stable opening, can achieve high efficiency,stability,low maintenance,to help customers get the maximum value.

1. High-speed Generation:

Our machine works at an amazing speed, conveying an uncommon generation yield of 130 sacks per miniature. This unmatched speed deciphers into expanded benefit and a critical competitive advantage.

2. Consistent Mechanization:

With progressed mechanization capabilities, our machine streamlines the bag-making handle, minimizing manual intercession and maximizing generation uptime. From cutting and folding to sealing and AI visual inspection automatically rejects waste, each step is immaculately executed, guaranteeing reliable quality and decreasing labor costs.

3. Predominant Sack Quality:

We take pride in creating packs of uncommon quality and toughness. Our machine utilizes state-of-the-art materials and cutting-edge fabricating procedures to make PP woven valve sacks that withstand requesting conditions and secure the astuteness of the cement they hold.

4. Adaptability and Customization:

Recognizing the different needs of our clients, our machine offers unparalleled adaptability in sack estimate, plan, and customization alternatives. Whether it's a particular sack capacity, branding necessities, or special plan highlights, our machine can fulfill each request, catering to a wide extend of cement producers.

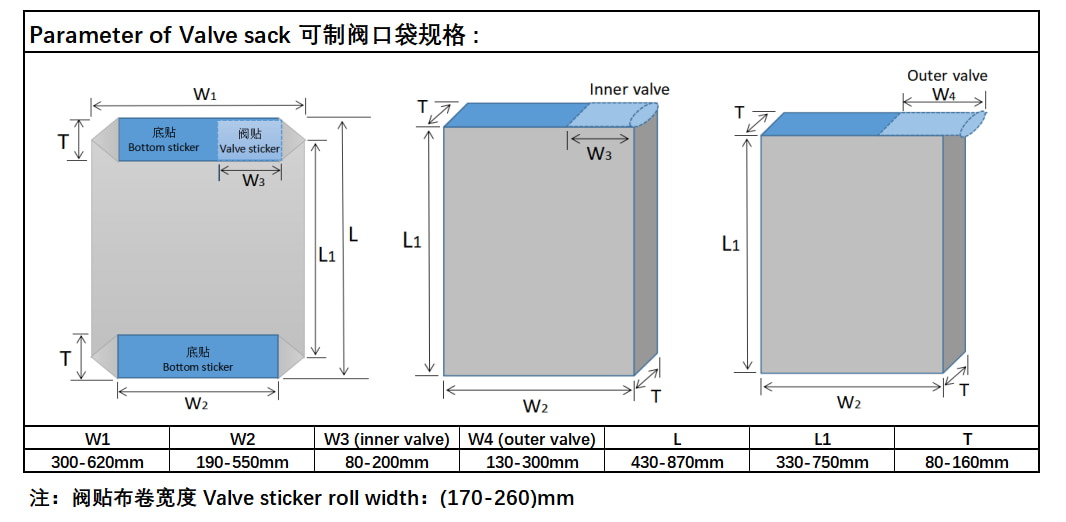

Valuablue specification of valve sacks:

SPECIFICATION OF VALVE SACK MAKING MACHINE

| Overall Dimension: | L11m*7.5m*2.5m (a temporary size due to a vertical and horizontal adjustment device at the machine bottom); |

| Weight: | About 17,000kg; |

| Power: | 3Ph380Vac±5%, 50Hz, three-phase and five-wire system (CE); |

| Installed Capacity: | About 150kW; |

| Production Speed: | 100 to 120 bags/min; |

| Air Supply: | Power≥0.6Mpa, working pressure≥0.5MPa, air consumption<350L/min (we supplier provide an air tank of 40L and extra air supply, if needed, should be prepared by customers themselves). |