Regarding pp woven sack making machine, Gachn group independently developed triangular bag opening structure does not require consumables, avoiding frequent shutdowns for replacement, and is ahead of Starlinger and W&H.

Product name :

PP woven block bottom valve sack making machineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

Xiamen,ChinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 months75g sack PP Woven Valve Sack Making Machine

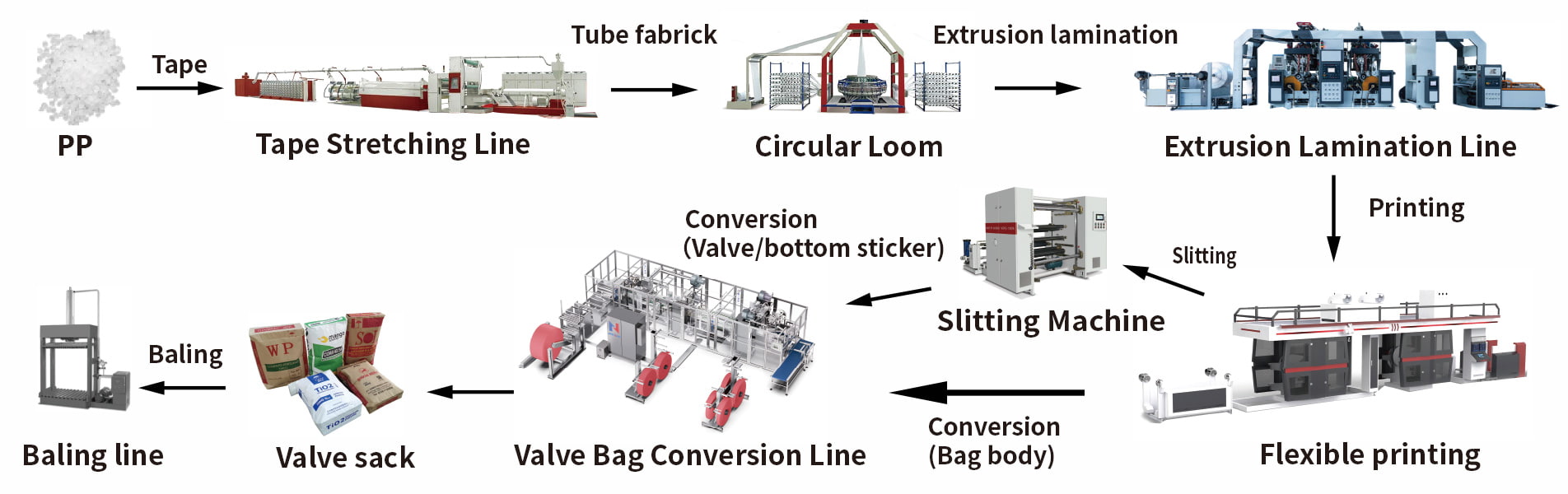

Welcome to our inventive and effective PP Woven Valve Sack Making Machine item page. As a plant proprietor, you get it the significance of ceaselessly making strides your generation capabilities to meet the developing request in different businesses. With the ever-increasing request for cement and other materials, our machine offers an proficient and dependable way to meet the developing showcase needs.Whether it's within the cement industry or other divisions requiring valve sacks, our machine gives a consistent generation prepare that complements existing hardware such as wire drawing machines, circular looms, and printing machines.

FEATURES

1.Advanced Bag Making Mechanism: The pp woven sack making machine is driven by 30 servo motors to achieve efficient and precise performance;

2.Strong adaptability: Our pp woven block bottom valve bag making machine can work with your existing front-end machines to produce new products-----PP woven square bottom valve bags. It complements front-end machines such as wire drawing machines, circular looms and printing machines, saving costs for the complete production line of bottom sealed valve bags.

3.Wide application industry: The valve bags produced by our machines can be used in many different fields: chemical raw materials, construction materials, modified plastics, food additives, carbon black pigment, ultrafine powder and other industries.

4.High production efficiency: With its advanced technology and automation, it maximizes production while reducing downtime, allowing you to meet large-volume needs and increase profitability. Our triangular bag mouth structure does not require suction cups, consumables, or downtime to replace consumables.

5.Reliable performance: Our pp block bottom sack machine are built to withstand a full production cycle. It combines powerful components and highlights high-quality craftsmanship to ensure long-term reliable and lasting performance in the future.

APPLICATIONS

1.Chemical crude materials :

Our valve sack making machine is able to deliver solid PP woven valve packs that have fabulous assurance against dampness, UV beams and physical harm. For case:

silica chemical bundling sacks, chemical fertilizer bundling sacks, CPE chemical bundling sacks, CPE granule bundling packs and other chemical fabric bundling sacks.

2.Building materials :

The PP woven valve sacks delivered by our valve sack making machine guarantee the secure capacity and proficient dealing with of building materials, making them an crucial fabric within 3.the development industry.

For case : cement bag,enhancing building materials bundling bags, gypsum building materials bundling sacks, putty powder building materials bundling sacks, building plastic bundling sacks, powder granule building materials bundling packs, color printing building materials valve packs,

4.Adjusted plastics :

Our valve pack making machine is able to create PP woven valve sacks that are exceptionally reasonable for bundling adjusted plastics. These sacks can keep up the quality and characteristics of plastic materials and keep up their astuteness all through the supply chain.

For case : unused fabric PE bundling sacks

5.Nourishment added substances :

Our valve sack making machine can deliver nourishment added substance bundling sacks.

6.Carbon Dark Color :

For the carbon dark color industry, our PP woven valve packs give fabulous security against light and dampness to preserve the color and characteristics of the color.

For case : white carbon dark PP valve sacks, carbon dark shade bundling sacks.

7.Ultrafine powder:

Our machines give exact control and consistency amid pack fabricating, making them perfect for bundling ultrafine powders. Our sack opening gadget and heat-sealed foot fixing strategy prevent powder spillage.

For case:ultrafine powder bundling sacks.

Contact us today to learn more about our PP Woven Valve Bag Making Machine and how it can add value to your business and increase your competitive edge . ↓ ↓ ↓