The chemical industry involves a wide variety of materials, including fertilizers, plastic particles, pigments and various chemical raw materials.

Product name :

Valve bags in the particle industryItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsValve bags in the particle industry

The chemical industry involves a wide variety of materials, including fertilizers, plastic particles, pigments and various chemical raw materials. These materials have extremely high requirements for packaging performance such as moisture resistance, leakage resistance and pollution resistance. With its unique valve port design, excellent sealing and physical properties, valve bags can fully meet the high standards of packaging in the chemical industry.

1. Typical applications of valve bags in the chemical industry

Fertilizer packaging

Fertilizers are susceptible to moisture and need to be stored for a long time. Valve bags effectively isolate moisture through sealing design to ensure no leakage during transportation and storage, while improving filling efficiency.

Plastic granule packaging

Plastic granules have strict requirements on the corrosion resistance and sealing of packaging. Valve bags can prevent granules from moisture, pollution or deformation, and ensure product integrity.

Chemical raw material packaging

Due to the characteristics of different raw materials (such as powder, granules or corrosive substances), valve bags can flexibly adapt to a variety of materials and specifications to meet diverse needs.

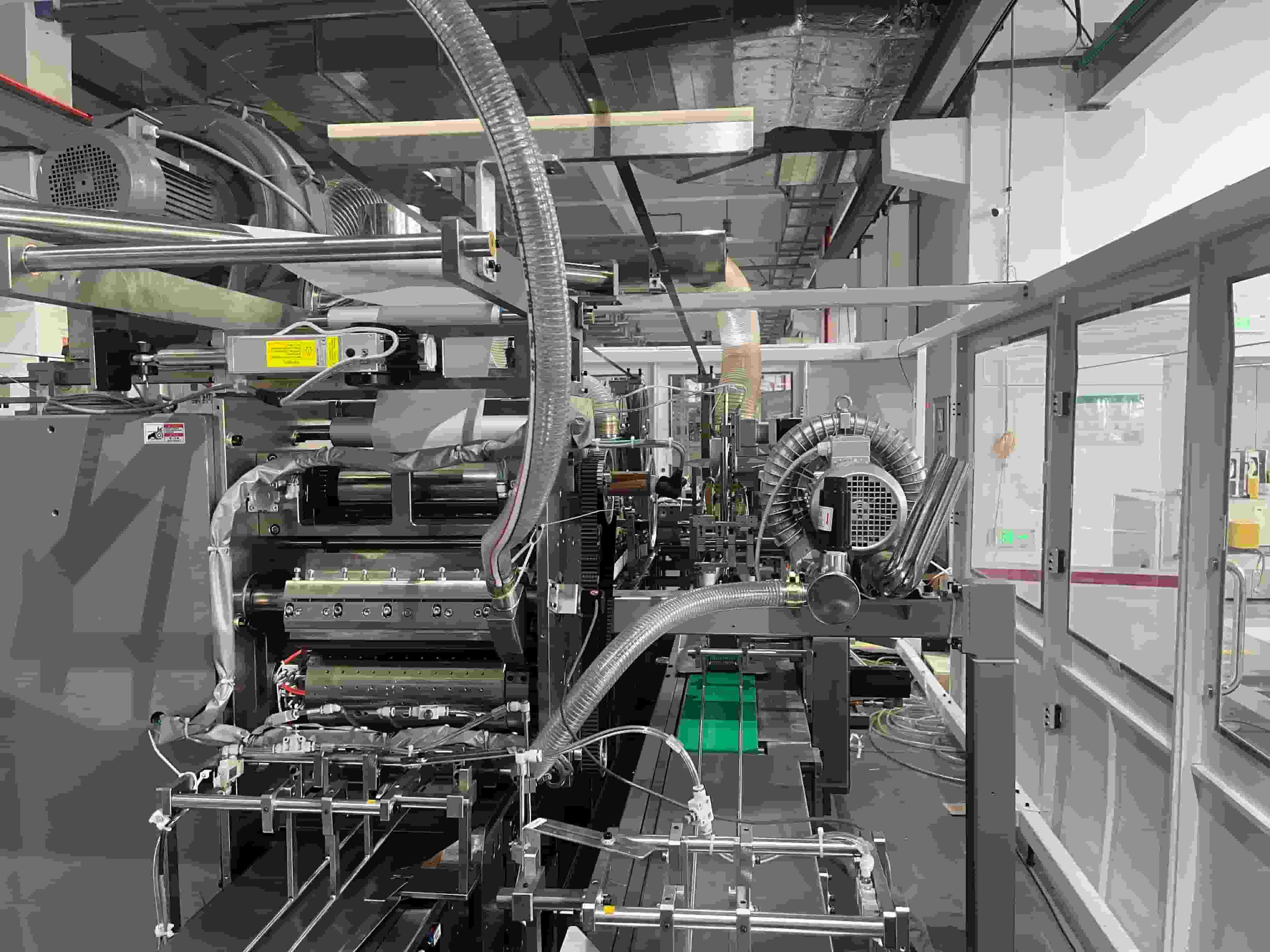

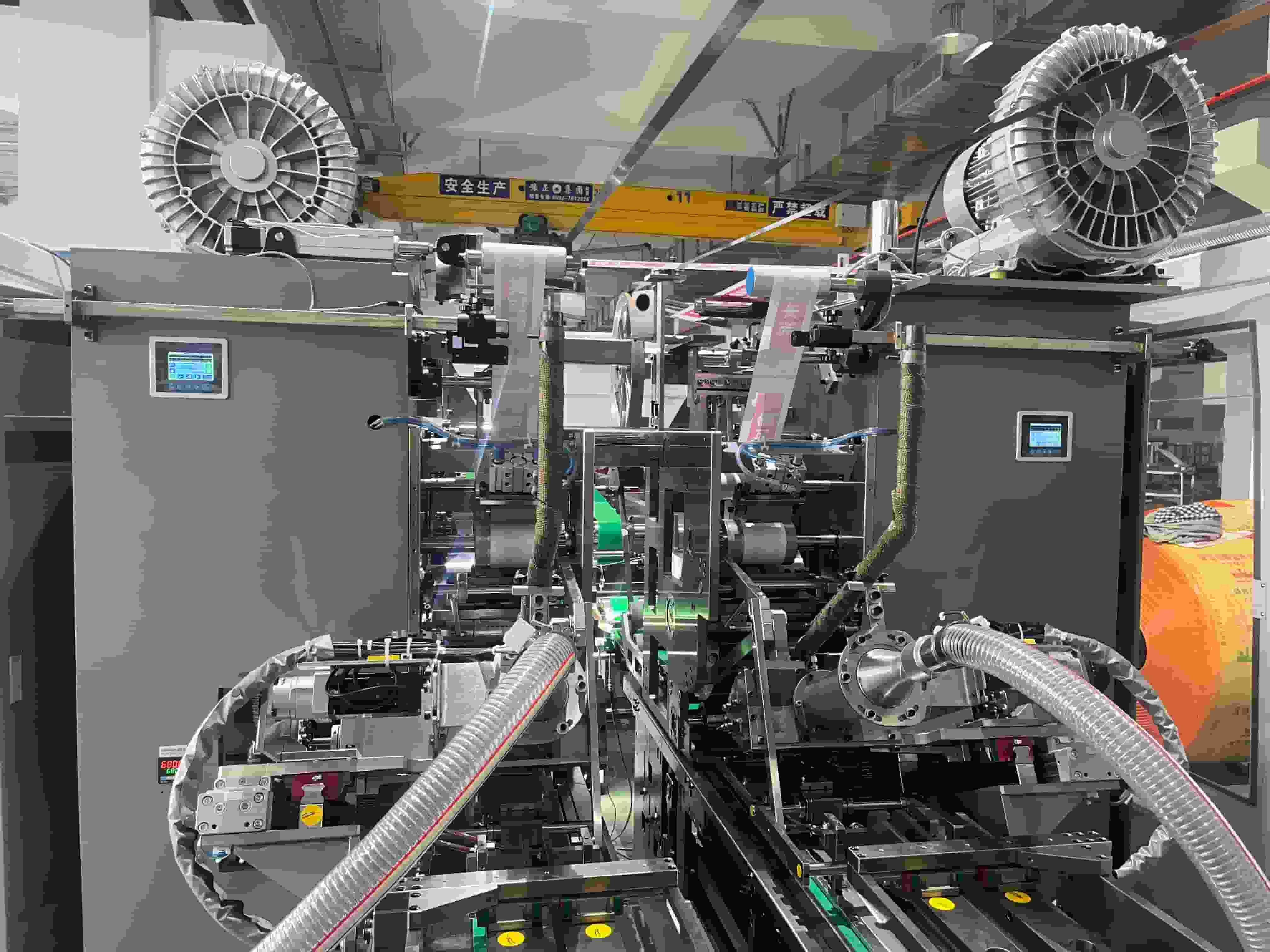

2. The core advantages of using Gachn group valve bag making machine to produce valve bags

Efficient production: The fully automated process significantly improves packaging speed and reduces labor costs.

Quality assurance: High-precision metering and deviation correction systems ensure accurate dimensions and avoid material waste.

Stable and durable: Using high-quality materials and advanced technology, fertilizer bag machine has a low failure rate and supports continuous production.

Space optimization: The compact structure (main machine size L9.5m×W7.0m×H2.2m) adapts to limited space and improves space utilization.

Environmentally friendly and sustainable: Valve bags are recyclable and have excellent open-air stacking performance, which helps the green development of the industry.

3. The unique advantages of Gachn Group's valve bag making machine

Accurate metering and quality control

Cement sack machine equips with a high-precision metering system with a low error rate to ensure product consistency and market competitiveness.

Flexible adaptation to diverse needs

Supports the production of multi-specification and multi-material valve bags to meet the complex scene requirements of the chemical industry.

Automation and intelligence

The PLC control system realizes the automation of the entire process of feeding, bag making, and sealing, reducing manual intervention.

Environmentally friendly design

Both gypsum sack machine and packaging meet environmental protection standards and support the circular economy model.

Gachn Group's valve bag making machine has become a key equipment in the packaging process of the chemical industry due to its high degree of automation, precise control, flexible adaptation and environmental protection performance. Its advantages are not only reflected in production efficiency and cost optimization, but also help companies cope with harsh production environments and market changes through stability and sustainability. Choosing Gachn equipment means providing efficient, reliable and green solutions for chemical packaging.