Gachn group valve bag making machine core highlights: intelligence and safety

Product name :

The Valve Bag Making Machine Integrating Intelligence and SafetyItem No :

FK008-IIIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsThe Valve Bag Making Machine Integrating Intelligence and Safety

Gachn group valve bag making machine core highlights: intelligence and safety

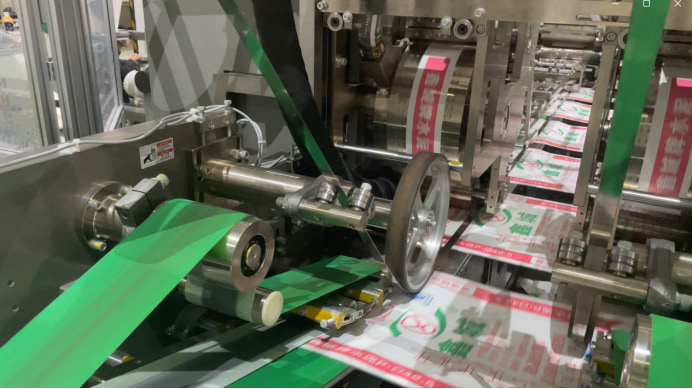

Full process automation of the equipment:

From unwinding, punching, welding to stacking, no manual intervention is required throughout the process, reducing labor costs.

Vacuum negative pressure transfer + photoelectric detection, photoelectric detection can automatically alarm and stop the machine when the bag transfer fails.

Ultra-high temperature welding technology:

Real-time temperature monitoring, power-off protection to prevent burning, adjustable blowing nozzle width, suitable for different bag types.

Core components

Visual inspection system: dual 4K cameras (Eco + Kangshida light source), infrared and black and white dual-mode detection, covering base fabric and bag mouth defects.

Pneumatic system: SMC/FESTO brand solenoid valve + cylinder, working pressure ≥0.5MPa, gas consumption <350L/min.

Durable design: exposed parts 304 stainless steel/chrome plating, transmission parts tempering and strengthening, life extended by 30%.

Precision processing technology:

The width of the triangle forming device is adjustable, the belt is pressed to prevent rebound, and the bag mouth is formed stably.

The folding device screw is adjusted, and the folding width is precisely controlled.

Gachn group valve bag bag making machine core highlights: design and process are both excellent

For example: valve bag bag making machine stacking unit

It has efficient stacking management: the servo conveying system supports customized stacking quantity, and the counting error is less than 0.1%.

Supports a variety of preset stacking and kicking modes (stacked/intelligent kicking, etc.)

Dynamic compensation algorithm can adapt to different bag sizes (25kg-50kg bags)

The automatic PP woven valve sack machine exporter stacking unit is an important part of the device, and the procedures it covers are responsible for stacking the bagged products according to the predetermined stacking method.

Through precise conveying control and positioning, the bagged products are placed one by one in the stacking area. The stacking method can be adjusted as needed, such as stacking, staggered, etc., and it is combined with the Gachn group valve bag bag making machine to ensure the stability and aesthetics of the stacking.

For example: track pressing device

First of all, the role of the track pressing device in the flatness of the bottom of the finished bag during the valve bag production process cannot be ignored. When the bag is conveyed to the discharge mechanism, the crawler belt will press the bottom of the bag appropriately. This pressing not only helps to remove air and wrinkles at the bottom of the bag, but also ensures that the bottom of the bag is flatter and tighter. This is crucial for subsequent stacking and transportation, because the flat bottom ensures that the bag is more stable when stacked and is not easy to slip or collapse.

Secondly, the crawler belt pressing mechanism also helps the smooth discharge of the finished bag. During the pressing process, the crawler belt will exert a certain thrust on the bag to help it slide smoothly from the conveyor line. This thrust not only helps to overcome the friction between the bag and the conveyor line, but also ensures that the bag maintains the correct direction and posture during the discharge process. Therefore, the discharge mechanism using crawler belt pressing can significantly improve the smoothness and accuracy of bag discharge.

In addition, the crawler belt pressing mechanism of the finished product stacking conveyor has the following advantages:

Wide adaptability: Automatic production valve sack machining supplier crawler belt pressing mechanism can adapt to bags of different sizes, thicknesses and materials, without frequent equipment changes or parameter adjustments.

Strong durability: automatic PP woven valve sack machine manufacturing company crawler tracks are usually made of wear-resistant and durable materials, which can withstand long-term continuous work without being easily damaged.

Easy maintenance: The structure of the crawler pressing mechanism is relatively easy to maintain and maintain. Even if a fault occurs, the operator can quickly locate and repair it.

The discharge mechanism in the Gachn group finished product stacking conveyor brings many advantages to the processing of finished product bags through crawler pressing. This mechanism not only improves the flatness of the bottom of the bag and the smoothness of the bag discharge, but also enhances the adaptability and durability of the equipment.