In the modern printing industry, efficient and accurate printing equipment is the key to ensuring production quality and efficiency.

Product name :

Printing machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsPrinting machine

In the modern printing industry, efficient and accurate flex printing process machinet is the key to ensuring production quality and efficiency. With its excellent performance and advanced technology, the GC 4+4 - 850 flexographic printing press is an ideal choice for printing wide and thin materials. Whether it is a roll of PP woven fabrics or other materials with high tension requirements, this printing press can easily handle it, ensuring that every print reaches the highest standards.

Equipment Highlights

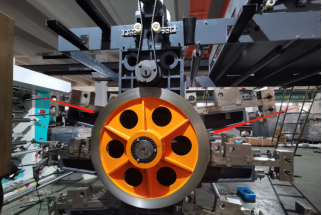

1. Satellite flexographic printing technology, high overprint accuracy

The GC 4+4 - 850 flexographic printing press adopts satellite flexographic printing technology. The printed material is close to the common printing cylinder, with small tension changes and small material deformation during drying. The machine has a compact structure and a short paper feed line. It is particularly suitable for printing wide and thin materials with difficult tension control. The overprint accuracy is extremely high, ensuring that each color is accurately aligned.

2. Efficient printing, both speed and quality

The maximum speed of this printing press can reach 200m/min, and the printing speed is 50-150m/min, which is suitable for a variety of printing needs. Whether it is 4-color printing on the front or 4-color printing on the back, GC 4+4 - 850 can easily cope with it, ensuring efficient production while maintaining excellent printing quality.

3. Automatic control, easy operation

6 colour flexo printing machine in China is equipped with an advanced automatic control system, including automatic tension adjustment, automatic deviation correction, servo motor drive, etc., to ensure that every link in the printing process is accurate and correct. The automatic EPC deviation correction system and online electronic registration function make the operation easier, reduce manual intervention, and improve production efficiency.

4. Multi-functional configuration, strong adaptability

GC 4+4 - 850 flexographic printing machine is equipped with a double-station unwinding and rewinding system, supporting a maximum coil diameter of 1500mm and adapting to a variety of material widths (550-850mm). The equipment is also equipped with a drying system, cooling system, corona treatment device, etc. to ensure that the printed material is quickly dried and maintains a good surface treatment effect.

Technical details

Printing material: roll PP woven fabric

Material width: 550-850mm

Maximum printing width: 700mm

Printing repeat range: 400-1200mm

Registration accuracy: horizontal ±0.15mm, vertical ±0.15mm

Total power consumption: 125KW

Machine weight: about 20 tons

Machine size: 16.8m (length) x 3m (width) x 4.3m (height)

Core configuration

| Servo motor traction: | 1 set |

| Satellite printing machine: | 2 sets |

| Printing unit drying system: | 2 sets |

| Drying system: | |

| Corona treatment device: | 1 set |

| Video detection system: | 2 sets |

| Central roller constant temperature system: | 2 sets |

| Enclosed scraper: | 8 sets (imported Danish technology) |

| Printing roller: | 8 pieces (customized size according to customer requirements) |

Parts list

GC 4+4 - 850 flexographic printing press uses many internationally renowned brand parts to ensure the stability and durability of the equipment. The main components include:

Human-machine interface: Huichuan

PLC programming controller: Huichuan

Servo motor: Shanghai Danma

Correcting system: Germany Best

Ceramic anilox roller: Shanghai Murata (Japanese technology)

Main bearings: Germany FAG / Japan NSK

Pneumatic components: Taiwan AirTac

Electric proportional valve: Japan Fujikura

Applicable fields

GC 4+4 - 850 flexographic printing press is widely used in printing in the fields of packaging, labels, films, woven bags, etc., especially suitable for printing wide and thin materials with high requirements for overprint accuracy. Whether it is mass production or high-precision printing, this stack flexo printing machine can meet your needs