In the field of powder material packaging, the filling efficiency and sealing performance of valve bags directly affect the production efficiency of enterprises.

Product name :

Intelligent temperature control valve bag forming machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsIntelligent temperature control valve bag forming machine

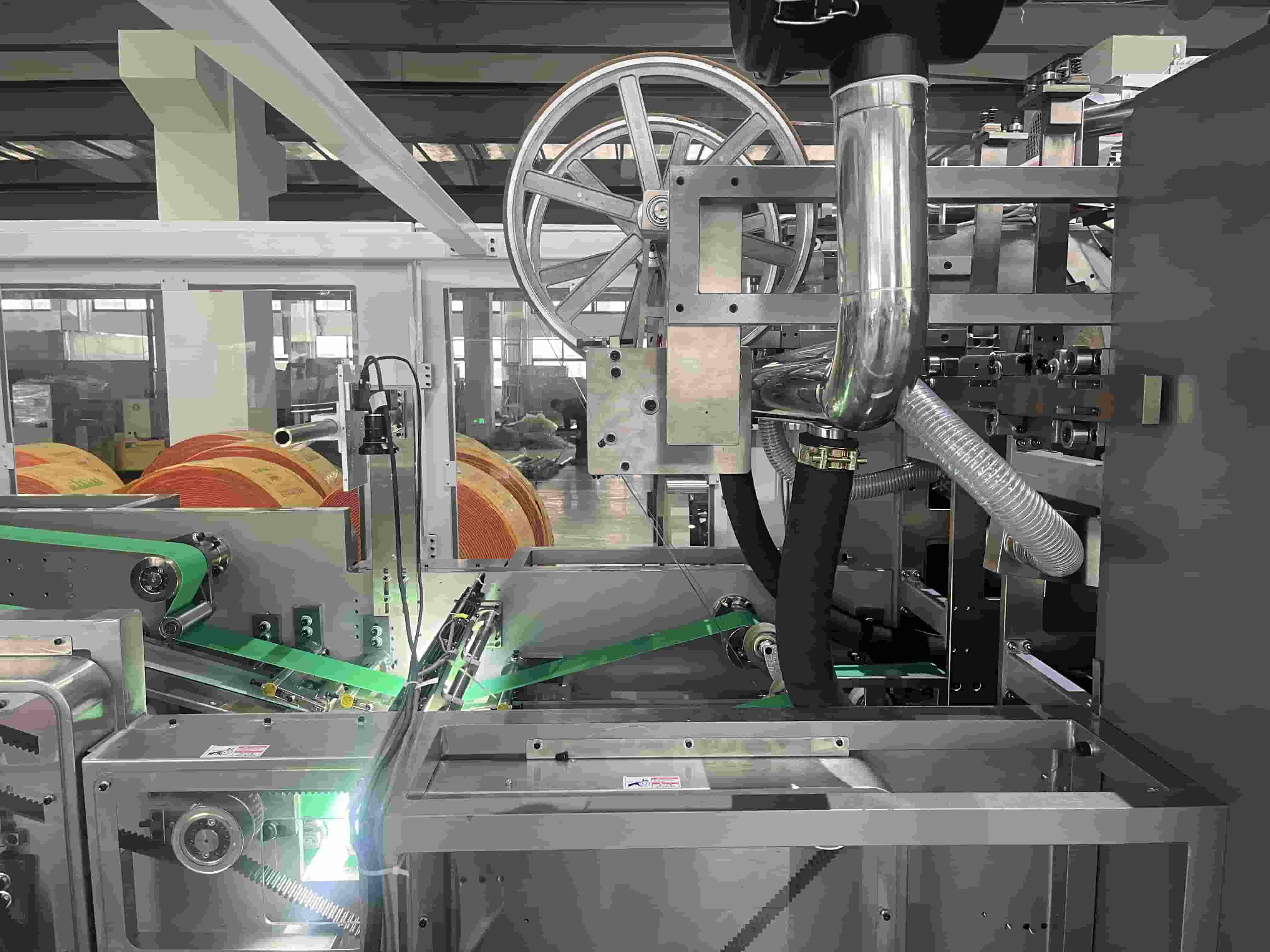

In the field of powder material packaging, the filling efficiency and sealing performance of valve bags directly affect the production efficiency of enterprises. As a leader in industry technology, automatic Lime sack machine manufacturer Gachn Group's valve bag making machine has become the preferred equipment for the global cement, chemical, food and other industries with its fully automated design, precise process control and low-carbon economy. Through precise temperature control and bottom sticker bonding technology, automatic lime sack machine can not only make PP bags to ensure that the bag's sealed bottom sticker does not break, but also make PE bags to ensure that the bag's sealing performance reaches 800 mesh powder without leaking the bag. Thus helping customers achieve the double breakthrough of "increasing production efficiency by 40% and reducing comprehensive costs by 30%".

Core advantages: Intelligent automation enables efficient production

1. High-speed filling without leakage

Precision microporous exhaust technology:

Equipped with a modular microporous roller device, the air exhaust speed during filling is increased by 50%, (cement and other high-density powders).

The micropore accuracy is ±0.05mm, the powder leakage rate is <0.01%, and dual protection against waterproofing and moisture is achieved at the same time.

2. Full process automation

GC intelligent bag insertion system:

Compatible with manual and mechanical bag insertion modes, supports ultrasonic valve port sealing, and the sealing strength after filling is increased by 200%.

The stacking neatness reaches 99%, the stacking height is increased to 8 layers, and the storage space is saved by 30%.

3. Heating sealing process

Patented hot air nozzle technology:

Servo control blow shaft precise positioning, welding temperature fluctuation ≤±1℃, scrap rate as low as 0.2%.

Supports seamless welding of materials such as PE and PP, and tensile strength is increased by 35%, meeting the packaging needs of heavy materials.

Gachn equipment realizes unmanned operation of the entire process of filling-sealing-palletizing.

Low-cost production: comprehensive optimization from raw materials to labor

1. Material saving technology

Lightweight design:

The film layer is evenly stressed, the thickness of the PP substrate is reduced by 20%, and the cost of raw materials per bag is reduced by 15%.

The pinhole-free sewing process avoids the waste of cloth cutting of traditional bottom-sewn bags, and the material utilization rate reaches 98%.

2. Zero adhesive process

Heat sealing replaces adhesive:

Eliminate the cost of adhesive and sewing thread, and reduce the production cost of a single bag by 25%.

The environmentally friendly process complies with REACH standards and has no risk of chemical pollution.

3. Efficient manpower allocation

Intelligent human-machine collaboration:

A single machine only requires 1 operator + 2 assistants, reducing labor costs by 50%.

The touch screen switches the bag size with one click, and the training cycle is shortened to 1 day.

Jia Chuang's patented heat sealing technology ensures zero defects at the bottom of the bag

Customer value: stable production and long-term benefits

Productivity breakthrough

The maximum production capacity of the automatic plaster sacks machine is 130 bags/minute, supporting 24-hour continuous production, and the annual production capacity is increased by more than 50%.

The modular design is easy to maintain, and the life of key components is extended to 5 years.

Green and sustainable

The heat recovery system reduces energy consumption by 25%, and the single machine reduces carbon emissions by more than 10 tons per year.

Supporting the mixed use of recycled materials up to 30%, helping enterprises achieve ESG goals.

Industry adaptability

Building materials: 50kg cement bags are produced with a breakage rate of <0.1% and a 40% improvement in drop resistance.

Food industry: Meets FDA standards, moisture-proof and anti-bacteria, suitable for packaging flour, feed, etc.

Chemical industry: Antistatic coating design, safe packaging of resin particles, dyes and other dangerous goods.