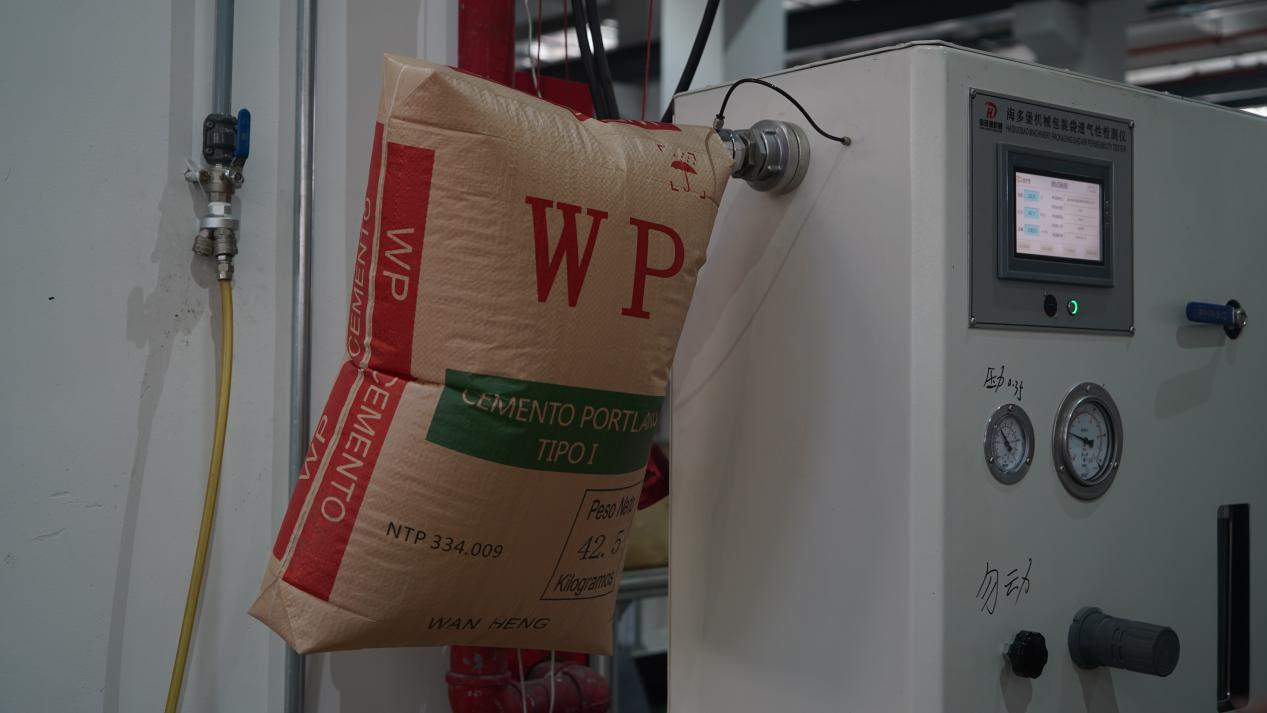

Gachn Group valve bag making machine has many advantages in the chemical industry, including high automation and production efficiency, precise metering and product quality, flexibility and diversified needs, stability and durability, space saving and improved site utilization, as well as environmental protection and sustainability.

Product name :

Independently Developed Adstar Bag MachineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsIndependently Developed Adstar Bag Machine

Gachn-Jeenar is a high-end intelligent equipment manufacturer integrating R&D, production, sales and after-sales service.

Jointly with the head office Xiamen Gachn Technology (stock code: 832368), we optimize resources and are committed to providing customers with the most professional services with the most outstanding technology. We have a high-end intelligent packaging equipment R&D and service team with more than ten years of practical experience, serving the global packaging industry.

The advantages of our company lie in its excellent mechanical design capabilities and electrical design capabilities. The main design direction is the domestic substitution of foreign equipment. It has rich processing resource integration capabilities, excellent performance in quality control and assembly capabilities, and the advanced equipment is in a leading position in the industry.

Focusing on the independent research and development of valve bag making machines, this product has won wide recognition in the market for its excellent performance and stability. The main parts and components of our equipment are provided by high-quality suppliers who have cooperated with Gachn Technology for more than ten years, ensuring the high quality and reliability of parts and components. In a modern workshop with 5S management, our technical workers use advanced intelligent assembly technology to carefully complete the assembly and commissioning of the equipment to ensure that every piece of equipment shipped can reach the best working condition.

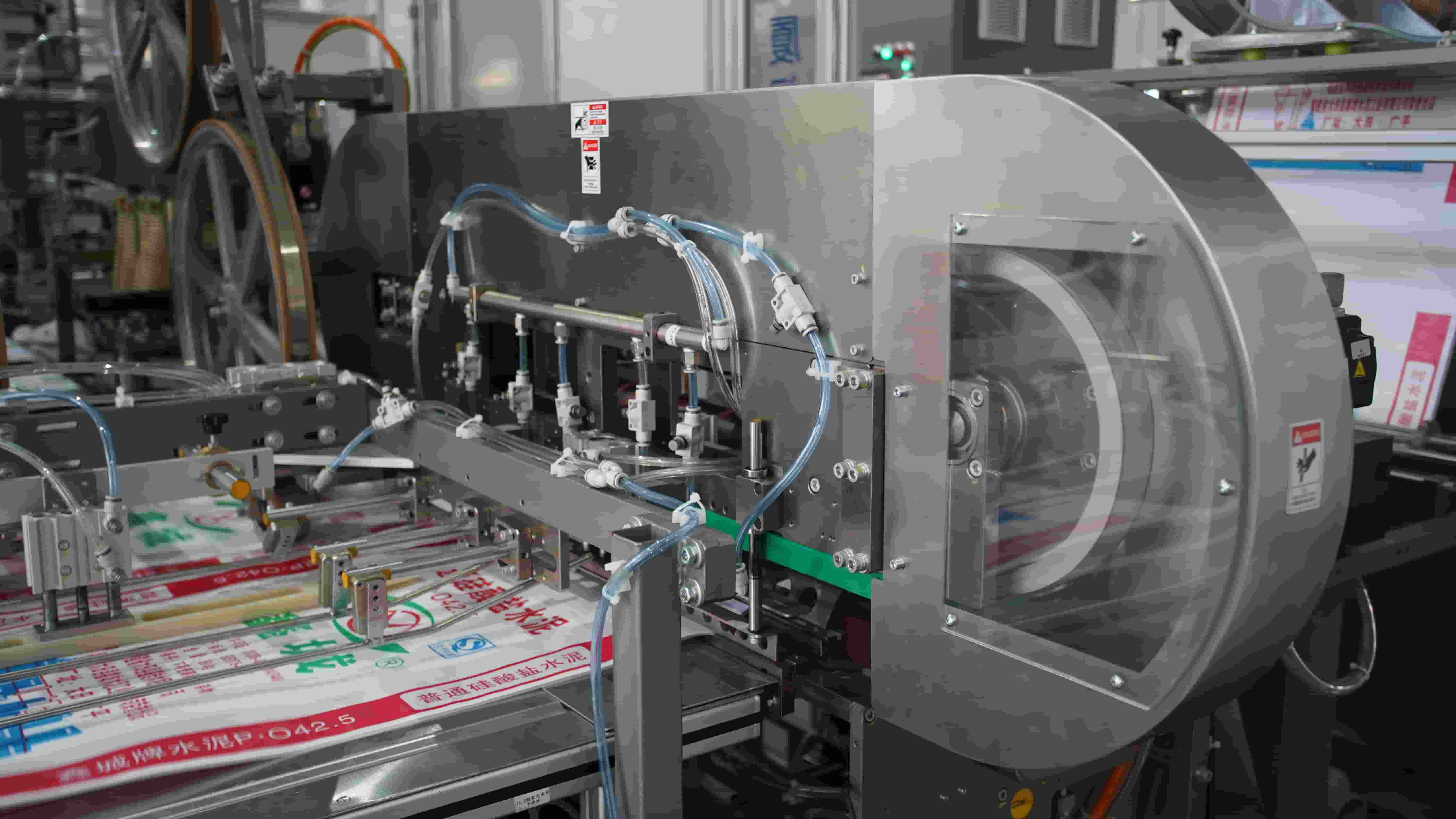

Core components and workflow of AD*STAR sack machine

The ADSTAR sack machine consists of 15 key components, and its workflow is as follows:

Bag unwinding device:

The traction motor drives the unwinding of the woven cloth coil to ensure stable material transportation.

The magnetic powder brake device provides stable unwinding tension control.

The air shaft fixes the material roll, and the lifting and lowering swing arm device adopts hydraulic control, which is easy to operate and can be operated by one person.

Bag making mechanism:

The cutting and transfer mechanism processes the coil into a bag body.

The bag opening device forms the bottom and valve of the packaging bag through opening and bag-shifting actions.

Heat sealing welding system:

The bottom sticker part adopts a unique heat sealing welding technology to achieve uniform blowing and constant size.

The constant temperature control system ensures stable and reliable welding temperature and improves welding firmness.

Finished product stacking and conveying device:

It has counting and stacking functions, and the counting specifications can be adjusted through the touch screen.

The data monitoring system combines cloud control technology to realize data collection and remote equipment diagnosis.

Equipment upgrade and testing

Visual inspection device: The visual inspection device can be upgraded later to automatically identify and remove problematic packaging bags.

Parts inspection: Precision tools such as coating measurement, micrometer, caliper, and various plug gauges are used to inspect parts to ensure that the quality meets the standards. At the same time, relevant hardness measurements are also performed to ensure the durability of parts.

The ADSTAR sack machine manufacture independently developed by Gachn Group ensures the stability and durability of the equipment with its advanced manufacturing process, high-quality spare parts, intelligent assembly and debugging process, as well as subsequent upgradeability and strict parts inspection. We are committed to providing customers with efficient, reliable, and intelligent valve bag making solutions to help customers achieve efficient production and maintenance.