Gachn Group will continue to be committed to technological innovation and process improvement to provide customers with more high-quality and efficient valve bag making solutions.

Product name :

High Speed Adstar Bag Making MachineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

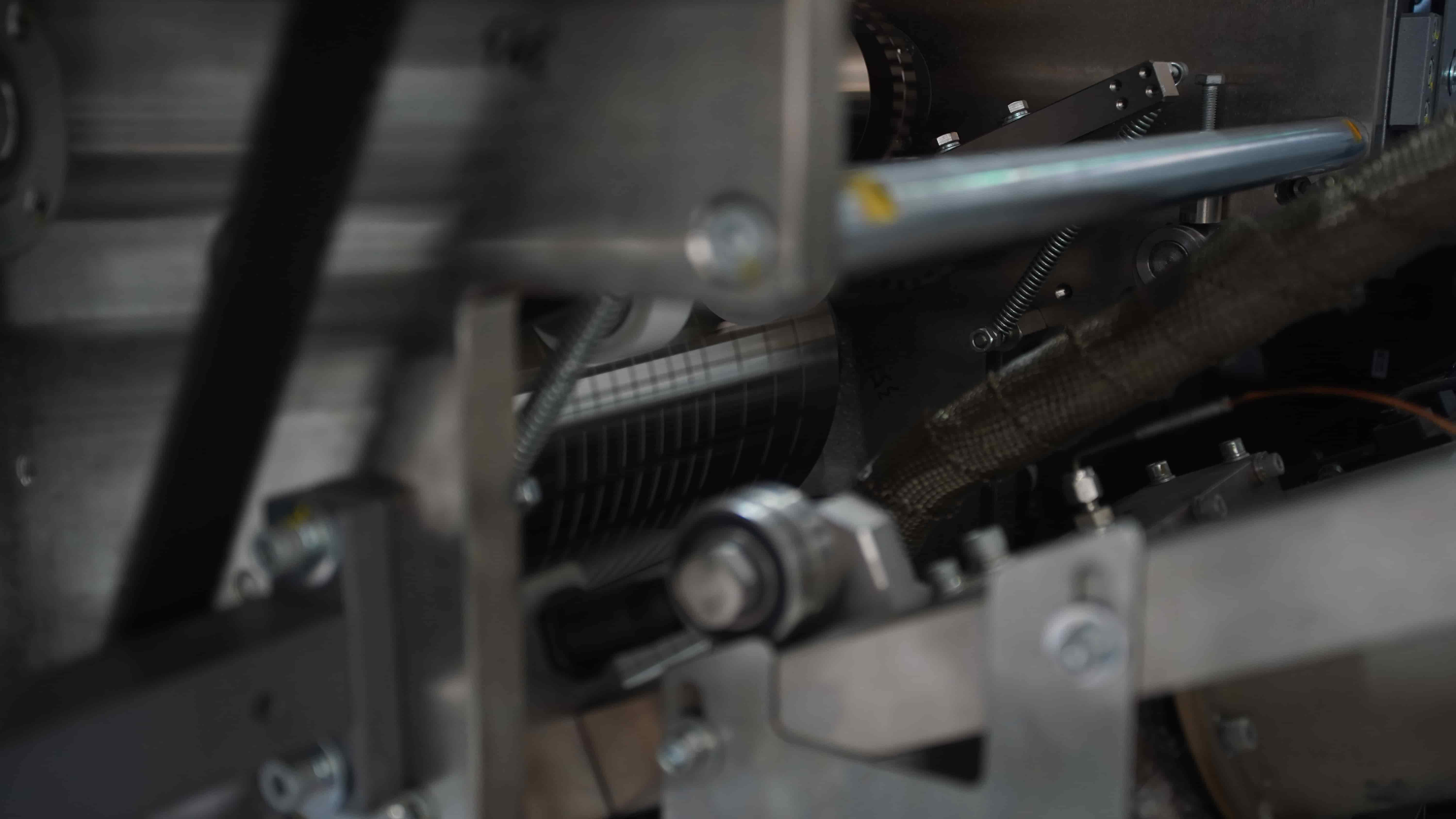

3 monthsHigh Speed Adstar Bag Making Machine

Demand for valve bags in the chemical industry:

In the chemical industry, there are many types of materials, including fertilizers, plastic particles, pigments, chemical raw materials, etc. These materials have different requirements for packaging, but generally require moisture-proof, leak-proof, and pollution-proof. Valve bags can meet the various packaging requirements of the chemical industry with their unique valve port design and excellent physical properties.

Application examples of valve bags in the chemical industry

Fertilizer packaging: Fertilizer is an important product in the chemical industry, and its packaging requirements are strict. Valve bags can ensure that fertilizers are not damp or leaking during transportation and storage, and are easy to fill and discharge. Accurately complete the packaging process of fertilizers and improve production efficiency.

Plastic granule packaging: Plastic granules are common materials in chemical production, and the sealing and corrosion resistance of packaging materials are required to be high. Valve bags can provide good sealing to prevent plastic granules from being damp, polluted or deformed during transportation.

Chemical raw material packaging: There are many types of chemical raw materials, and the requirements for packaging are also different. Valve bags can adapt to valve bags of different specifications and materials to meet the diverse packaging needs of chemical raw materials.

Advantages of valve bags in the chemical industry

Improve production efficiency: can greatly improve packaging speed, reduce manual operation time, and reduce production costs.

Ensure product quality: valve bags have excellent sealing and corrosion resistance, can protect materials from pollution and damage from the external environment, and ensure product quality.

Reduce manual dependence: fully automatic valve bag converting machine reduces dependence on manual labor, reduces labor costs, and avoids the impact of human factors on product quality.

Save space: valve bags have compact structure and small footprint, can make full use of production space, and improve the utilization rate of production sites.

Why do you recommend you to use valve sack converting machine to produce chemical valve bags?

Gachn Group's automatic cement sack machine adopts advanced automation technology and realizes the automation of the entire packaging process through the PLC control system. It can automatically complete a series of packaging processes such as feeding, metering, bag making, sealing, and conveying, thereby significantly reducing manual intervention and improving production efficiency. In the chemical industry, this highly automated equipment can greatly increase packaging speed and reduce production costs.

1. Accurate measurement and product quality

Gachn Group's valve bag making machine is equipped with a high-precision metering system and a correction system, which can accurately control the size of the bag, achieve accurate and stable coil conveying, and meet the high requirements of the chemical industry for product quality. Accurate measurement not only avoids waste and errors, but also improves the overall quality and competitiveness of the product.

2. Flexibility and diversified needs

Gachn Group's valve bag making machine can adapt to valve bags of different specifications and materials to meet the diverse packaging needs of the chemical industry. Whether it is powder or granular. Gachn Group's valve bag making machine can provide suitable packaging solutions. At present, the flexibility of Gachn Group's valve bag making machine enables the chemical industry to respond more flexibly to changes in market demand.

3. Stability and durability

Gachn Group's valve bag making machine is made of high-quality materials and advanced technology, and has good stability and durability. It can ensure long-term stable operation, reduce failure rate and downtime, thereby reducing maintenance costs and production costs. In the chemical industry, this stability and durability are essential to ensure the continuity and stability of the production line.

4. Save space and improve site utilization

Gachn Group's valve bag making machine has a compact structure, and the main machine has three-dimensional dimensions: L9.5m×W7.0m×H2.2m. There is a height adjustment device at the bottom, which can make full use of the production space. In the chemical industry, production sites are usually limited, so saving space is crucial to improving production efficiency. The compact design of the valve bag making machine enables it to better adapt to various production environments and improve the utilization of production sites.

5. Environmental protection and sustainability

As an environmentally friendly packaging bag, the valve bag has excellent sealing, moisture-proof, waterproof and anti-fouling properties. It can be stacked in the open air for easy transportation and storage, and the internal product does not melt, agglomerate, lose quantity or quality. In addition, the valve bag is easy to recycle, which is conducive to protecting the ecological environment. In the chemical industry, environmental protection and sustainability have become increasingly important issues, and the use of valve bag making machines helps promote the green development of the industry.

In summary, Gachn valve bag making machine has many advantages in the chemical industry, including high automation and production efficiency, precise metering and product quality, flexibility and diversified needs, stability and durability, space saving and improved site utilization, as well as environmental protection and sustainability. These advantages make valve bag making machine one of the indispensable packaging equipment in the chemical industry.