Gachn Group AI inspecition System Of Adstar Valve Sack Making Machine

The core component of Gachn group is a 4K color high-precision CCD camera with a resolution of up to 4096*1, which is responsible for capturing the front and back of the incoming coil and the image of the finished bag.

Product name :

Gachn Group AI Inspecition System Of Adstar Valve Sack Making MachineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsGachn Group AI inspecition System Of Adstar Valve Sack Making Machine

Gachn group's Valve Bag Making Machine AI Vision Inspection System Factory integrates advanced AI learning and visual measurement technology and mechanical automation control, aiming to efficiently and accurately identify and handle quality problems in cement bag coil raw materials and bag making processes. At present, Gachn group's visual inspection speed can reach the fastest: 140 pieces/minute, rejection rate = ≥96.5%, leakage rejection rate <0.15%, and can cover the installation of valve bag making machines of various international brands.

AI visual inspection technology has shown strong capabilities and advantages in dealing with challenges such as large amounts of raw material returns, difficulty in manual bag picking, and difficulty in controlling product quality. Through efficient identification and classification of raw materials, automated processing of return materials, reduced labor intensity, improved accuracy, and real-time monitoring and feedback, the AI visual inspection system provides companies with reliable quality control methods, which helps to improve product quality and production efficiency. This article aims to introduce you to the technology and advantages of Gachn group's AI visual inspection equipment:

AI deep learning technology:

Unlike traditional rule-based or template matching detection methods, Gachn group's equipment uses advanced AI deep learning algorithms. This means that it can continuously learn from actual detection data and optimize the detection model, thereby improving the accuracy and efficiency of detection.

The introduction of AI enables the equipment to recognize and process more complex image features, including but not limited to the shape of the bag, printing, and potential defects that are invisible to the human eye.

Close cooperation with mechanical structure:

The Valve Bag Making Machine AI Vision Inspection System VS-Ⅲ Factory not only relies on AI technology, but also fully considers the coordination with various mechanical structures. Through precise sensors and mechanical control, accurate detection of valve bags at all links in the production line is achieved.

This close cooperation ensures the efficiency and stability of the detection process and reduces the possibility of false alarms and missed alarms.

The advantages of Gachn group Valve Bag Making Machine Vision Inspection System VS-Ⅲ Manufacturer compared with international first-line brands:

| No. | Process | Waste Type | W&H Or Starlinger | Gachn Group |

| 1 | Fabric waste | Holes (including markings or labels) |

It is necessary to manually label the bags in the previous process, and then the bag-making machine uses sensors to determine whether there is a specific label on the bag to remove the waste; [It has great limitations and relies on manual judgment. If the worker does not label it or labels it off-center, the bag-making machine will not be able to identify it or make mistakes] |

Our visual inspection can identify these defects, and there is no need for manual labor to affix this mark in the previous process; |

| 2 | Joint | |||

| 3 | Weft deviation | |||

| 4 | Sparse tape | |||

| 5 | Scratching | |||

| 6 | Side abrasions | |||

| 7 | Overlapping threads | |||

| 8 | Waste from bag making process | Bottom patch with remarks, holes, weft deviation, joints | This type of defect requires manual marking in advance before it can be detected. [Limitations are large. If the worker does not mark it in time, the bag making machine cannot detect it.] | Our visual inspection can identify these defects, and there is no need for manual labor to affix this mark in the previous process; |

| 9 | The bottom is not fully folded (Skew) | Sensors cannot detect these defects. | Our visual inspection can identify these defects and remove it. | |

| 10 | Overlapping Fluctuation (Not overlapped) | |||

| 11 | The valve patch is folded or skewed | |||

| 12 | No bottom patch | |||

| 13 | Bottom patch offset | |||

| 14 | The bottom patch is folded | |||

| 15 | No punched hole | |||

| 16 | No valve patch | |||

| 17 | Bottom Skew |

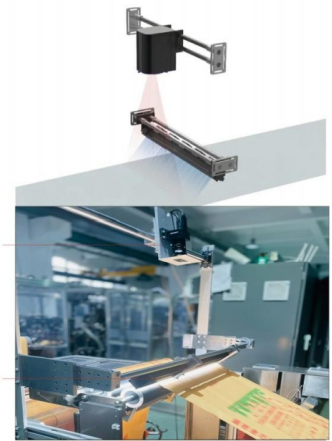

Gachn group AI visual inspection mechanical composition CCD detection system:

The core component of Gachn group is a 4K color high-precision CCD camera with a resolution of up to 4096*1, which is responsible for capturing the front and back of the incoming coil and the image of the finished bag.

The AI visual inspection camera is equipped with a high-sensitivity sensor and a suitable optical lens to ensure that clear and high-quality images can be obtained under various lighting conditions.

Mechanical system:

Gachn group AI visual inspection system includes coil conveying device, bag making machinery and NG product discharge mechanism-etc.

During the inspection process, the conveyor is responsible for smoothly and continuously delivering the coil into the inspection area. The bag-making machine completes the forming and sealing of cement bags according to the preset parameters. The NG product discharge mechanism is responsible for removing the detected unqualified products from the production line.

Encoder:

It is used to provide accurate position information of the coil movement to ensure that the camera can capture images online in real time.

The encoder signal is synchronized with the camera shooting timing to ensure the accuracy and continuity of image acquisition.

Industrial computer and inspection software:

As the processing center, the industrial computer is responsible for receiving the image data transmitted by the camera.

The inspection software has built-in advanced image processing algorithms and machine learning models, which can quickly and accurately analyze and identify images. The software can automatically determine whether there are defects in the coil and finished product (such as unstable overlap, damage, stains, size discrepancies, etc.), and output the inspection results.

Gachn group AI working principle and advantages Image acquisition:

The coil enters the inspection area driven by the conveyor.

The encoder monitors the coil position in real time, and when the coil reaches the predetermined shooting position, it triggers the camera to collect images.

Image processing and inspection:

The image collected by the camera is transmitted to the industrial computer.

The inspection software pre-processes the image (such as denoising, enhancement, etc.), and then analyzes the image using image processing algorithms and machine learning models. The software determines whether the coil and finished product are defective according to the preset quality standards.

Gachn group AI visual inspection can help you:

Solve the problem of excessive raw material return:

Efficient identification and classification: The AI visual inspection system can use deep learning algorithms to efficiently and accurately identify and classify raw materials. Through the training model, the system can identify different types of raw materials, including return materials and new materials, so as to achieve accurate identification of return materials.

Automated processing: Once the return materials are identified, the AI visual inspection system can automatically trigger the corresponding processing mechanism, such as removing the return materials from the production line or sending them to a specific recycling area. This can effectively reduce the risk of return materials mixing into new products.

Improved accuracy: Compared with manual bag picking, the AI visual inspection system has higher accuracy. The system can identify small differences and ensure that only raw materials that meet quality standards are selected.

Improve product quality control capabilities:

Real-time monitoring and feedback: The AI visual inspection system can monitor the product quality on the production line in real time. Once a quality problem is found, the system will immediately remove the bag and provide detailed inspection results and location information. This helps companies to find and solve problems in a timely manner and prevent bad products from entering the market.

Data analysis and optimization: The system can also collect a large amount of inspection data. Through data analysis, companies can understand the weak links in the production process, and then optimize the production process to improve product quality.