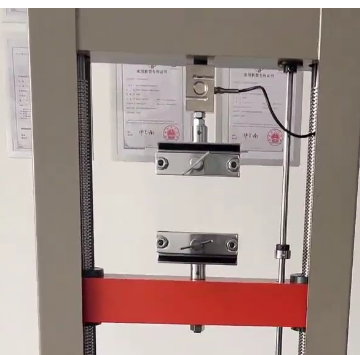

GC 026 PG electronic fabric strength tester (pneumatic fabric clamp, specially designed for testing the mechanical properties of various fabrics. With high-precision sensors, intelligent control and diversified functions, the equipment can accurately complete tests such as stretching, tearing and peeling.

Product name :

Electronic fabric strength machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsElectronic fabric strength machine

GC 026 PG electronic fabric strength tester (pneumatic fabric clamp, specially designed for testing the mechanical properties of various fabrics. With high-precision sensors, intelligent control and diversified functions, bursting strength Electronic fabric strength machine can accurately complete tests such as stretching, tearing and peeling. It is widely used in the quality inspection of traditional fabrics such as cotton, wool, linen, silk, as well as special materials such as non-woven fabrics, coated fabrics, industrial fabrics, etc., fully meeting the stringent requirements of the textile industry for strength, durability and standardization.

Core advantages

Accurate and reliable

High-precision force sensors (accuracy ≤±0.5%) are used to ensure that the data is authentic and reliable.

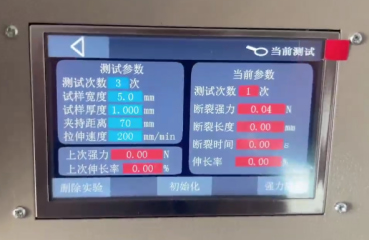

Dynamic curve tracking technology displays the changes in parameters such as stretching, elongation, and time in real time, and supports multi-dimensional data comparison.

Efficient and convenient

Pneumatic clamp design, fast and stable clamping, avoids sample damage, and improves test efficiency and repeatability.

The test speed is steplessly adjustable from 1 to 600 mm/min, supports automatic shutdown and upper and lower limit protection, and is safe and worry-free to operate.

Intelligent and versatile

Built-in multi-national standards (GB/T, FZ/T, etc.), supports customized test solutions, and adapts to diverse testing needs.

The software supports multi-language switching between Chinese and English, and data can be exported in Excel, Word, and PDF formats, which is convenient for laboratory networking comparison and management.

Stable and durable

Double-column gantry structure, the body is stable and durable, and the effective range is up to 600mm, which meets the needs of large-scale testing.

Adopting advanced components, the response speed and control accuracy are both excellent, ensuring the long-term stable operation of the equipment.

Technical parameters

Range selection: 500N / 1000N / 3000N / 5000N (customizable on demand)

Clamp distance adjustment: 25~500mm (steplessly adjustable)

Stretching speed: 1~600mm/min (free setting)

Resolution: elongation accuracy 0.01mm, no omissions in data recording

Compatibility: flexible selection of pneumatic/manual clamps, suitable for a variety of test scenarios such as single yarn, fabric, and coating materials

Power supply and size: AC220V±10% / 50Hz; 820mm×600mm×1600mm (compact design, space saving)

Applicable fields

Quality inspection agency: ideal tool for GB/T 3923.1, GB/T19976 and other standard certifications.

Textile enterprises: raw material strength verification, production process optimization and finished product quality control.

Scientific research units: fabric mechanical properties research, new material development and data modeling.

Gachn group- Your Professional Partner

As an industry-leading technology company, Xiamen Jiachuang Technology drives quality with innovation and provides customers with:

Customized services: flexible customization of software functions, algorithms, and report formats to meet personalized needs.

Global support: multi-language operation interface, efficient after-sales service network, to ensure worry-free use of equipment.

Intelligent interconnection: high-speed port directly connected to the computer, database management + historical data tracing, to help digital upgrades.