In the field of packaging manufacturing, precise shift control and stable winding technology are the core to ensure the quality of bag forming.

Product name :

Edge moving machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsEdge moving machine

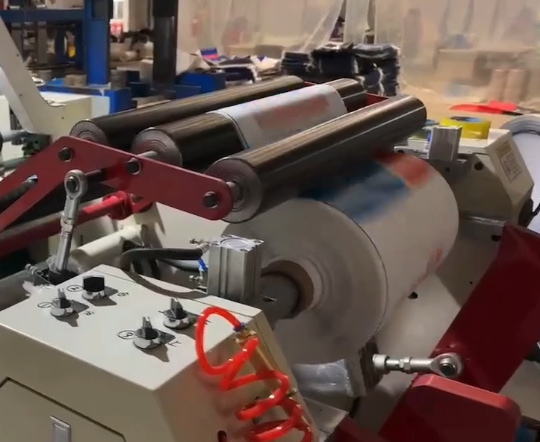

In the field of packaging manufacturing, precise shift control and stable winding technology are the core to ensure the quality of bag forming. The GC650 displacement unit integrates servo drive, constant tension winding and intelligent control. It is designed for efficient bag forming and is suitable for a variety of materials with a width of 260-650mm, helping enterprises to achieve high-precision, low-loss automated production.

Core advantages

1. Servo drive, precise control

Independent motor control: The shifting device and the winding device are driven by servo motors respectively, with a speed range of 20-260m/min, supporting synchronous acceleration and deceleration to ensure seamless connection between shifting and winding actions.

Constant tension winding: The center winding technology is equipped with a servo motor + reducer, which can flexibly adjust the winding torque, the coil is flat and has no slack, and the forming quality is stable.

High-precision deviation correction: The servo photoelectric deviation correction system monitors the material position in real time, with an error of ≤±0.2mm, reducing the scrap rate.

2. Modular design, flexible adaptation

Multi-specification compatibility: supports mother roll diameter Ф500-1500mm, suitable for films, woven bags and other materials of different sizes.

Quick changeover: the forming plate and the clamping device can be adjusted quickly, and the parameter switching can be completed within 30 minutes to meet the needs of small batch customization

3. Intelligent and efficient, easy to operate

Human-machine interaction interface: the speedometer displays production data in real time, one-button start and stop, automatic fault alarm, and reduces manual intervention.

Low energy consumption operation: the total power is only 13kW, the air flow rate is 0.2m³/min, and the comprehensive energy consumption is 15% lower than that of similar equipment.

Technical parameters at a glance

| Item | Parameters |

| Applicable width | 260-650mm |

| Production speed | 20-260m/min |

| Maximum diameter of reel | Ф500-1500mm |

| Overall machine dimensions | 9.5×1.3×1.6m (length×width×height) |

| Overall machine weight | 2 tons |

| Input power | 380V industrial power supply (standard) |

Equipment composition and core configuration

1. Unwinding unit

Hydraulic shaftless feeding: the air expansion shaft (3-inch standard) is combined with an automatic lifting device to easily cope with large roll diameter materials.

Air brake + automatic tension: the magnetic powder brake adjusts the tension in real time to prevent the material from running off or breaking.

2. Shifting device

Circular shifter + forming plate: accurately control the bag size, support large and small edge insertion processes, and adapt to various bag requirements.

Pinch roller device: driven by servo motor to ensure that there is no stretching deformation during the material shifting process.

3. Center winder

Flattening roller + swing device: eliminate the internal stress of the coil and rewind tightly and evenly.

3-inch air expansion shaft: fast unloading design to improve roll changing efficiency.

4. Electrical system

Servo drive + variable frequency speed regulation: Schneider/Panasonic core components, stable operation, life up to 100,000 hours.

Standard tool box: contains solenoid valves, relays, photoelectric switches and other vulnerable parts, easy maintenance.

Applicable scenarios

Flexible packaging industry: automatic forming and rewinding of food bags, shopping bags, and garbage bags.

Industrial packaging: efficient processing of building materials moisture-proof film and chemical woven bags.

Customized production: small batch flexible manufacturing of medical bags and special material bags.

Why choose GC650?

Precision and efficiency coexist: 260m/min high-speed production, ±0.2mm correction accuracy, and 30% increase in production capacity.

Durable: key components are imported from Japan and Germany (servo motors, bearings), and the failure rate is lower than the industry standard.

Worry-free after-sales: Gachn Technology provides full technical training, 24-hour remote support, and fast response to spare parts.

The GC650 displacement unit is centered on intelligent control, modular design and excellent stability, providing packaging companies with a one-stop solution from material loading to finished product winding. Whether it is large-scale continuous production or high-precision customization needs, this equipment can help you seize market opportunities with efficient and reliable performance