Gachn Group has 200 + patents and strong R&D technical capabilities, including 16+ patents for valve bag making machines.

Product name :

Cemeng Bag Making Machine Valve Bag PP WovenItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

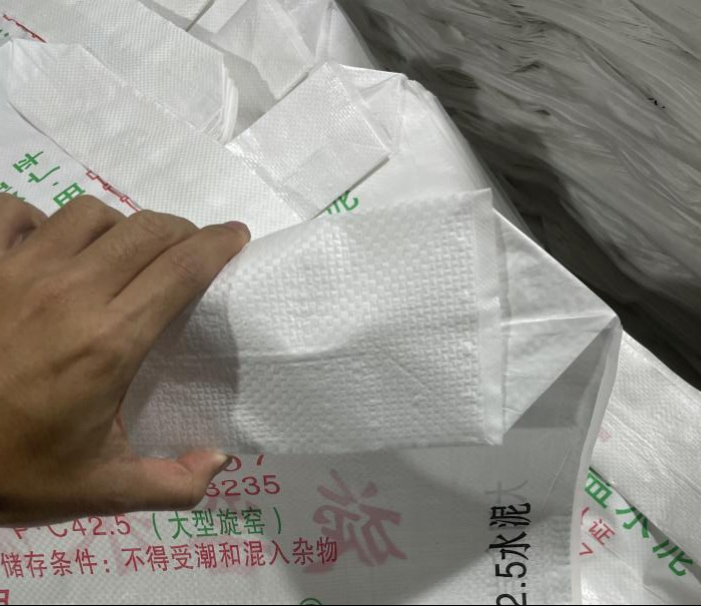

3 monthsCemeng Bag Making Machine Valve Bag PP Woven

GACHN valve sack making machine is an automated equipment designed for the production of valve bags. Gachn group valve bag conversion line adopts advanced mechanical design and control technology, which can efficiently and accurately complete the valve bag making process, greatly improving production efficiency and product quality.

Technical features Production problems and solutions

Problem 1: The sealing of the valve port does not meet the standard

The sealing does not meet the standard. Unstable valve ports are prone to leakage during storage or transportation. This will not only cause waste of materials, but also pollute the surrounding environment. If different types of materials are stored in the valve bag, poor sealing may cause cross-contamination between materials, thereby affecting the quality and cost of the materials.

Solution: Gachn Group uses precise valve port forming molds and heat sealing technology, combined with precise control of pressure and temperature, to ensure the consistency and reliability of the valve port sealing performance.

Problem 2: Uneven bag thickness

When the bag body with uneven thickness is under pressure, the thinner part may be more likely to break or deform. This will cause the load-bearing capacity of the valve bag to decrease, and it cannot effectively protect the stored materials. During transportation or stacking, the bag body may break due to the pressure, resulting in leakage and waste of materials.

Solution: Through the precise control of the servo motor, combined with the uniquely designed tension adjustment system, the stable transmission of the cloth roll during the bag making process is ensured to avoid uneven thickness.

Problem 3: Low production efficiency

When producing valve bags, if the valve sack conversion line accuracy is insufficient, the product quality will be unstable, which will affect the production efficiency.

If the equipment fails or is improperly maintained, the production line will be shut down, which will affect the production efficiency.

Solution: Optimize the production process, adopt high-speed servo drive and automatic control system, reduce manual intervention, and improve production efficiency. At the same time, it supports continuous operation and batch production to meet the needs of large-scale production.

Equipped with high-precision control system: Advanced PLC control system realizes intelligent management of automated production processes. Compared with international brands, Gachn group servo system has 15 more servos, realizing a more comprehensive control system.

Touch screen human-machine interface, easy and intuitive operation, supports multiple production parameter settings and adjustments.

Efficient bag making mechanism: driven by servo motor to ensure high-precision control of bag length, bag width and other dimensions.

The unique valve port forming device ensures that the valve port structure is stable and has excellent sealing performance.

Problem 4: Serious material waste

If the bag thickness of the valve bag is uneven, more materials may be required during the production process to ensure the overall strength of the bag. This will not only increase production costs, but also affect production efficiency. In addition, due to uneven thickness, the weight of the bag may also vary, which will increase the difficulty and cost of packaging and transportation.

Solution: Use an intelligent cutting system to accurately calculate the amount of material according to production needs and reduce the generation of scraps. At the same time, it supports waste recycling and reuse to effectively reduce material costs.

Customer Cases and Feedback

Case 1:

After a large foreign bag-making company adopted the valve bag making machine of Gachn Group, its production efficiency was greatly improved, and the valve port sealing pass rate was as high as 99.8%, which significantly reduced production costs and defective rates.

Case 2:

According to feedback from Chinese bag-making companies, the valve bag making machine of Gachn Group is easy to operate, has low maintenance costs, and produces valve bags with excellent sealing performance, which effectively prevents the leakage of grain during storage.