Gachn Group adstar bag making machine has excellent bottom sticker production technology.This process is designed to accurately and stably fit the pre-prepared bottom sticker material to the predetermined position of the valve bag to ensure the sealing, stability and durability of the bag.

Product name :

Cemeng Bag Making Machine Adstar BagItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsCemeng Bag Making Machine Adstar Bag

By improving the performance of the automatic Valve bottomer CONVERTEX,We have improved the production efficiency and product quality of valve bags to meet the growing market demand.

1. Bottom sticker material preparation and conveying

Conveying process:

The bottom sticker material is conveyed through Gachn Group's unique double-station rolling mechanism. During the conveying process, the automatic Valve sack making equipment is equipped with sensors to monitor the position and status of the material in real time to ensure that the material is always in the correct position. The mechanism is reasonably designed to ensure the smooth and continuous conveying of the material and avoid wrinkles or deviations during the conveying process.

2. Bottom sticker transfer and positioning

Transfer device:

Gachn Group automatic valve bag converting machine adopts a uniquely designed bottom sticker transfer device, which uses a precise mechanical structure and a full servo control system to achieve accurate transfer of the bottom sticker.

The transfer device is equipped with a precise deviation correction device, which can monitor and adjust the position of the bottom sticker in real time to ensure that it is always consistent with the predetermined position of the valve bag opening.

Positioning process:

After the bottom sticker material is fed into the transfer device, it is smoothly placed on the bottom of the bag through a series of complex and coordinated actions (such as adsorption, movement, and bonding).

During the positioning process, the machine uses advanced positioning technology and sensors to ensure that the bottom sticker can be accurately attached to the bottom of the valve bag.

3. pressing and sealing

Pressing device:

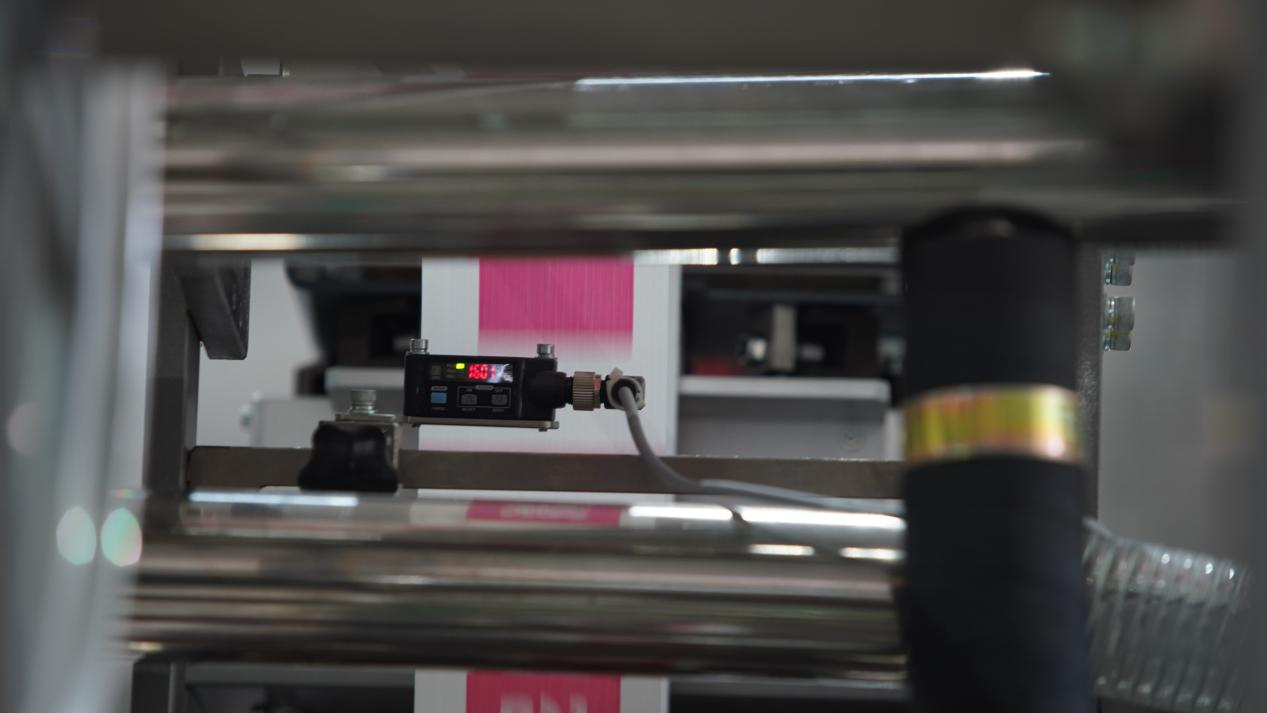

In order to ensure that the bottom sticker fits tightly with the bottom of the bag, the bag making machine is equipped with a professional cutter and adsorption roller device.

The pressing device uses appropriate pressure and temperature to make the bottom sticker material tightly combined with the bottom of the valve bag to form a firm seal.

Sealing performance:

During the pressing process, the machine ensures that the sealing performance reaches the best state by accurately controlling the pressure of the adsorption roller and the temperature of the hot air gun.

The position of the bottom sticker of the valve bag after sealing can pass the quality inspection to ensure that it will not leak or break during use.

4. Automation and intelligent features

Real-time monitoring:

Gachn Group's valve bag making machine uses advanced sensors and control systems to monitor the status and position of the bottom sticker in real time, automatically adjust the transfer parameters, and ensure the stability and continuity of the production process.

Intelligent management:

The intelligent management system can record and identify the data generated by production problems, providing strong support for subsequent process optimization and quality control.

Summary

The system also has automatic alarm and fault diagnosis functions, which can promptly issue alarms and provide solutions when problems occur.

The bottom sticker transfer process of Gachn Group's valve bag making machine is a complex and delicate process, which is directly related to the quality and adhesion of the valve bag. By continuously optimizing process technology and improving equipment performance, we can further improve the production efficiency and product quality of valve bags to meet the growing market demand. In the future, Gachn Group will continue to be committed to technological innovation and process improvement to provide customers with more high-quality and efficient valve bag making solutions.