Gachn group valve bag making machine have visual inspection equipment with unique design from GACHN GROUP is one of the important steps for enterprises to upgrade their industry, which will help improve their competitiveness in the market.

Product name :

Carbon Dark Color Packaging Bag Making MachineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsCarbon Dark Color Packaging Bag Making Machine

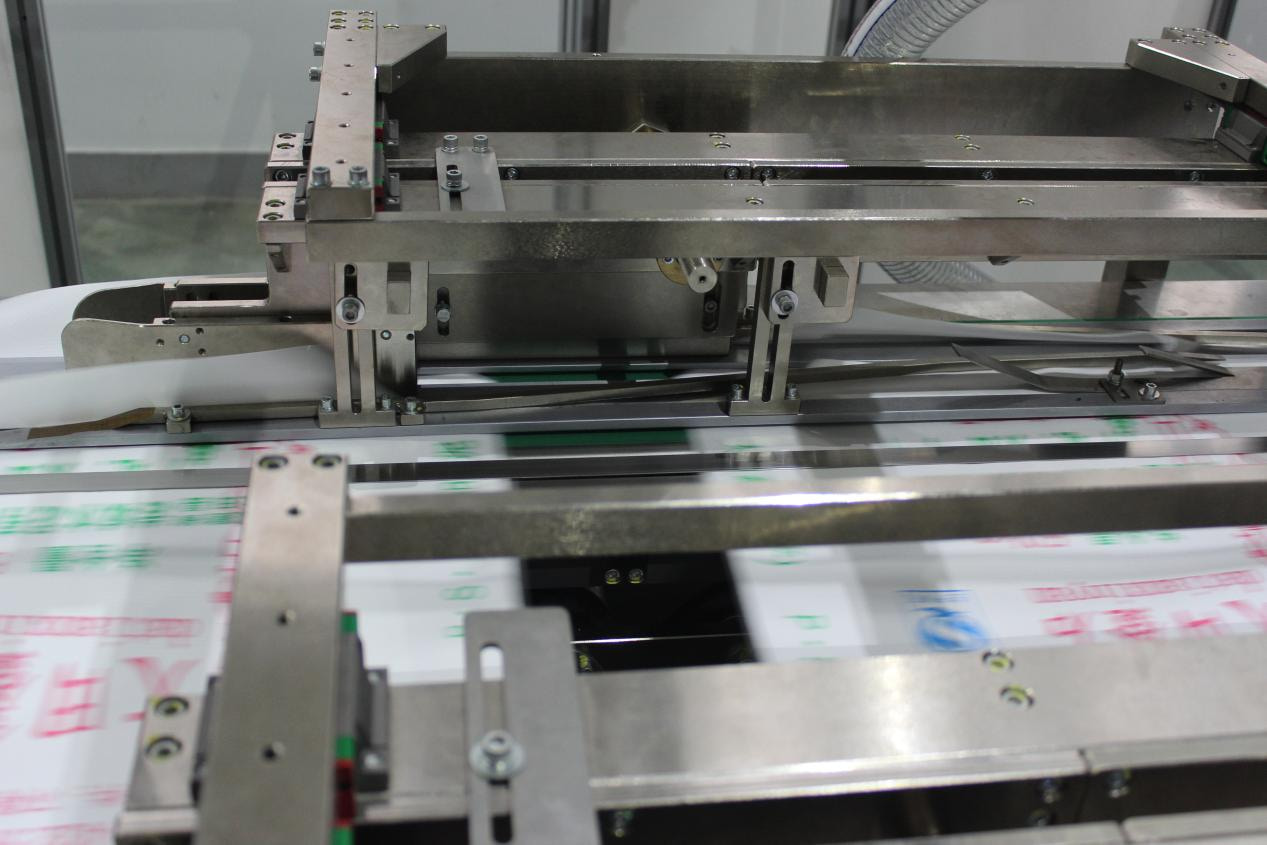

Gachn valve bag bag making machine bag making section technology

Gachn Group automatic pp woven sack making machine equipment model FK008 is a highly automated production equipment, mainly used to make valve bags. The equipment has advanced technical configuration and excellent performance, and can meet the production needs of bags of various specifications and materials.

The front end of the automatic valve sack making machine consists of multiple components, including bag unwinding device, micro-hole punching device, unwinding traction device, bag making device, conveying device, and each component plays a vital role. The bag making section composed of these mechanisms ensures that the equipment does not jam the bag during production and ensures the flatness of the bag, thereby improving the production quality and aesthetics of the valve bag for customers. This article will introduce you to the unique design of the bag end equipment of Gachn vautomatic pp woven block bottom valve bag making machine:

Bag unwinding device:

Gachn Group's bag making machine adopts passive unwinding working mode. The material unwinding is driven by the traction motor, and it is equipped with a magnetic powder brake device to ensure stable and reliable material unwinding. The expansion shaft fixes the material roll, and the lifting and lowering swing arm device is controlled by a cylinder. The loading and unloading of materials is convenient and reliable, and the operation is simple. When the material roll is almost used up, the equipment will sound an alarm to notify the personnel to replace the material roll. The whole machine is equipped with a floating tension rod with adjustable tension to maintain constant tension during operation.

Micro-hole punching device:

The micro-hole needle roller adopts modular splicing assembly, which is easy to replace and maintain. The size of the micro-hole can be adjusted by the screw plus handwheel structure.

Unwinding traction device:

It adopts servo motor to control it separately, and the manual valve controls the cylinder to realize the convenient operation of opening and closing the clamping roller and threading the material. The transfer mechanism is equipped with a floating tension rod with adjustable tension. The constant tension of the cloth roll is kept stable during operation to ensure the bag making device.

Bag making device:

It includes mechanisms such as pulling material, color mark, and rear end cutting. It has two bag making methods: color mark and fixed length, which can be set on the touch screen.

Conveying device:

The bag bottom forming device consists of a triangle forming device and a belt conveyor; in the triangle forming device, two sets of triangle plates work in turn to ensure efficient and stable forming, and the plate width is adjustable to adapt to bags of different sizes; the belt conveyor ensures that the bag mouth is completely closed. The conveying unit adopts crawler bag pressing to make the bag out smoother. This design can release and stack a certain number of bags at a time, and the number can be set on the screen; the conveying adopts a servo motor as the driving device, and the conveying distance can be set on the screen. This enables the equipment to be precise and stable, ensuring that customers have stable, high-speed, beautiful, and high-strength welding.