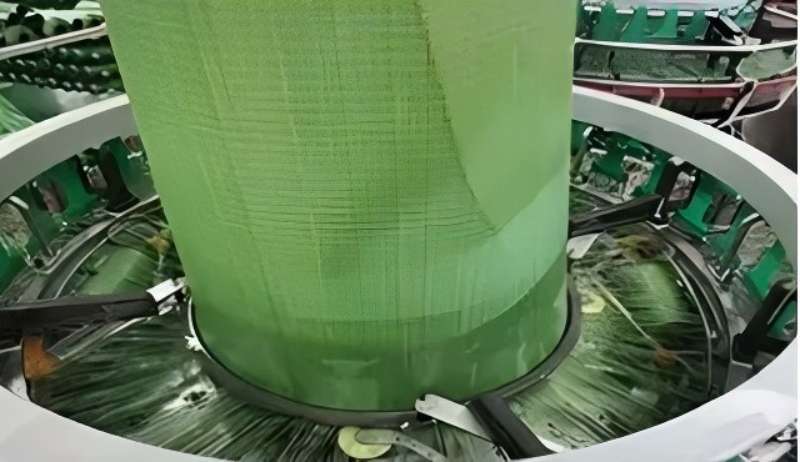

The GC-850-6S circular loom is an efficient and versatile fully automatic circular weaving equipment designed for high-density double flat fabrics.

Product name :

Automatic Circular LoomItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsAutomatic Circular Loom

The GC-850-6S circular loom (circular loom machine) is an efficient and versatile fully automatic circular weaving equipment designed for high-density double flat fabrics. It is suitable for yarn width of 1.8mm and the maximum effective weaving width is 630mm. The equipment adopts 6-shuttle high-speed weaving technology, supports 1200 weft insertions per minute, and combined with 720 warp yarns, it can quickly produce high-precision industrial fabrics, packaging materials and special fabrics. Its modular structure and intelligent control meet the diversified production needs and are the preferred equipment for the textile industry to improve production capacity and quality.

Core advantages

High-speed and efficient production

6-shuttle linkage system: equipped with 6 sets of independent shuttles, the weft insertion speed reaches 1200 times/minute, and the spindle speed is up to 160rpm, which significantly improves weaving efficiency.

Wide width adaptation: supports double flat fabric width of 400-800mm (300-400mm or 750-850mm in speed reduction mode), and flexibly responds to different product specifications.

Precision yarn control

Warp management: 720 warps are independently fed, equipped with a 0.15kW double warp feeding motor, with uniform and stable tension to reduce the risk of yarn breakage.

Intelligent winding system: 1.6Nm torque winding motor, suitable for a maximum fabric winding diameter of 1200mm, flat winding, and support continuous production.

Durable and reliable design

Core structure: Grommet belt with heddle wire system, enhances weaving stability and extends circular weaving loom life.

High compatibility: Suitable for φ38×230mm yarn tubes, maximum warp winding diameter of 160mm, weft winding diameter of 115mm, reducing the frequency of material changes.

Power optimization: The main motor power is only 3kW, and with a 0.37kW winding motor, the energy consumption is 15% lower than similar products in the industry.

Technical parameters

| Category | Parameter details |

| Weaving capacity | Double flat fabric width 400-800mm (standard mode) / 300-400mm or 750-850mm (speed reduction mode) |

| Weft insertion speed | 1200 times/minute |

| Spindle speed | Maximum 160rpm |

| Warp configuration | 720 independent warp yarns, suitable for φ38×230mm yarn tubes, maximum winding diameter 160mm |

| Winding system | Fabric winding diameter maximum 1200mm, winding tube inner diameter 102mm, torque 1.6Nm |

| Motor configuration | Main motor 3kW / winding motor 0.37kW / warp feeding motor 0.15kW×2 |

| Equipment size | Surface winding width 850mm, suitable for industrial standard production environment |

Core function highlights

Intelligent speed regulation: support high-speed and speed reduction mode switching to adapt to different yarn strength and fabric density requirements.

Precise tension control: The independent warp yarn supply system is equipped with electronic tension adjustment to ensure uniform and flawless weaving.

Quick material change design: The lateral length of the yarn tube is 203mm, and the winding diameter compatibility is strong, which improves production continuity.

Applicable scenarios and materials

Product types: industrial canvas, container bags, geotextiles, waterproof tarpaulins, agricultural covering films, etc.

Applicable yarns: PP, PE, polyester and other chemical fiber yarns, with a width of 1.8mm, support high-density weaving.

Installation and operation requirements

Power supply configuration: Standard industrial three-phase power supply, it is recommended to be equipped with a voltage stabilizer to ensure 6 shuttle circular loom stability.

Environmental requirements: Dry and ventilated workshop, avoid dust pollution, and regularly maintain the heald and shuttle components.

Choose the GC-850-6S circular loom to empower your textile production with efficient weaving technology, and achieve a double leap in quality and speed.