Automatic PP woven valve bag machine Supplier Gachn group's technology and adstar bag making machine have been widely used by more than 50 customers in three continents and regions around the world, and it provides woven products for many industries such as petrochemicals, cement building materials, agricultural supplies, food packaging, etc. every year.

Product name :

Automatic PP Woven Valve Bag Machine For Adstar BagItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsAutomatic PP Woven Valve Bag Machine For Adstar Bag

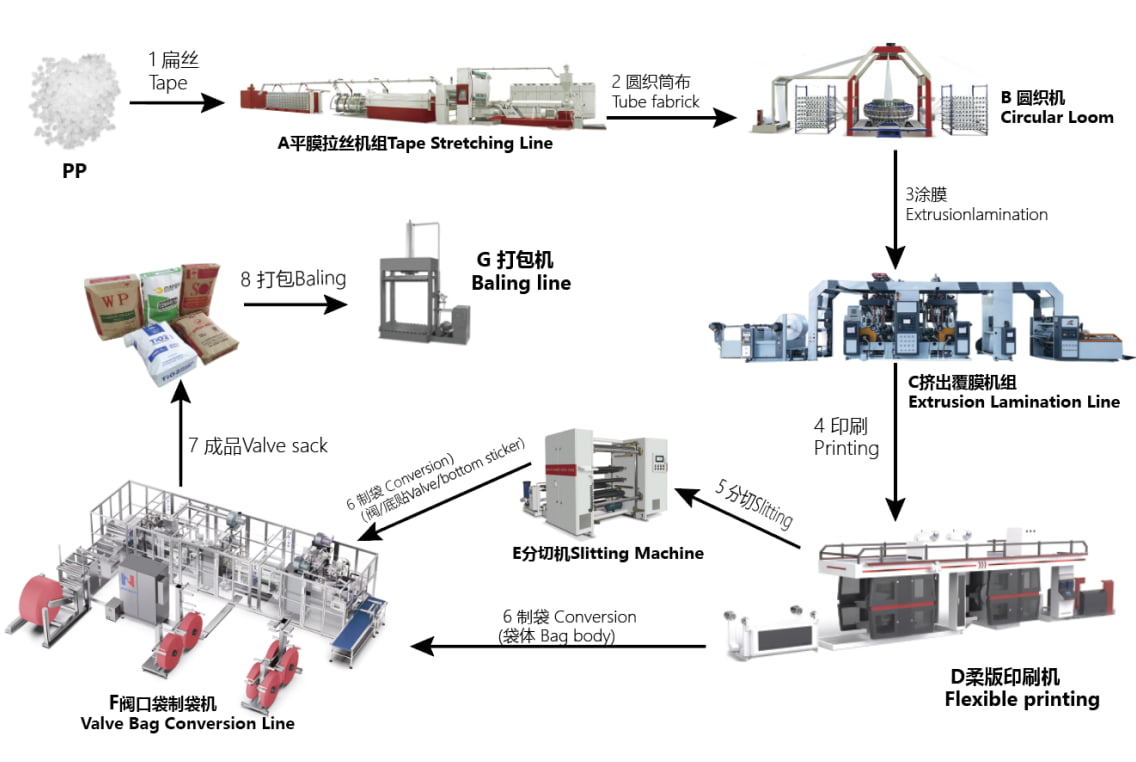

Since the first sanitary packaging machine of Gachn group was launched in 2011, the company has continued to lead the innovative development of China's plastic packaging industry with its outstanding R&D strength, strict equipment quality control system and global market layout. Today, Gachn group has grown into a multinational industrial equipment giant, with Gachn Technology and other companies that are leading in the global industry. Its product line covers the entire field of plastic weaving equipment, and can provide customers with a full set of plastic weaving equipment solutions including wire drawing machines, circular looms, printing machines, bag making machines, recycling granulators, etc.

Automatic PP woven valve bag machine Supplier Gachn group's technology and equipment have been widely used by more than 50 customers in three continents and regions around the world, and it provides woven products for many industries such as petrochemicals, cement building materials, agricultural supplies, food packaging, etc. every year. These technologies and equipment not only represent the quality assurance of high-quality plastic weaving products, but also become the first choice of many investors.

automatic PP woven valve bag machine Manufacturing companies Gachn group's valve bag making machine is popular mainly due to its following advantages:

Better product quality

Advanced technical design:

The whole machine is equipped with a 30-axis servo system and a separate servo-controlled material transfer mechanism to ensure reliable welding position. The welding and bonding position can be adjusted through the touch screen and buttons before and after.

The whole machine includes two sets of visual modules 4K, two sets of light sources, data statistical analysis, kicking waste conveying and other structures.

The visual module is used for AI data statistical analysis and imaging analysis of product quality, which can identify and remove defects such as bottom sticker defects, bag opening abnormalities, bag body holes, punching offsets, joints, and bottom sticker whitening. Reduce the cost of manual inspection of bags and reduce the outflow of abnormal bags.

International customer trust: After actual application verification by more than 50 customers around the world, Gachn group's equipment has performed well in performance, stability and durability.

Higher product quality and raw material utilization: Due to the high precision of the equipment, it can produce higher quality and stronger woven products, while improving raw material utilization and reducing production costs.

Environmental protection and energy saving:Automatic PP woven valve sack machine Supplier Gachn group's equipment fully considers environmental protection and energy saving factors when designing, and adopts advanced energy-saving technology and materials to reduce raw material consumption and environmental pollution.

The cost of plastic woven products is mainly composed of raw material cost, energy consumption, labor cost, management cost, depreciation cost and loss. Gachn group helps customers reduce production costs in the following ways.

Raw material cost: Due to the high precision of the equipment, it can accurately control the ultra-high temperature heating gun to reduce waste. At the same time, the use of technical means such as controlling the reciprocating rotation mechanism of the blowing shaft to achieve wind direction switching can improve the accuracy and strength of the bottom sticker, so that lighter bags can be used to meet packaging requirements under the same strength requirements, thereby reducing raw material costs.

Other costs: By optimizing the equipment structure and production process, during the lamination process, the machine accurately controls the pressure of the adsorption roller and the temperature of the hot air gun to ensure that the sealing performance reaches the best state.

The position of the bottom sticker of the valve bag after sealing can pass the quality inspection to ensure that it will not leak or break during use. Reduce labor costs, management costs, depreciation costs and losses, etc., so as to help customers reduce overall production costs.

With its outstanding technical strength, strict quality control system and global market layout, Gachn group provides high-quality plastic weaving equipment solutions to customers around the world. Its equipment not only represents high-quality product assurance, but also helps customers reduce production costs, improve production efficiency and market competitiveness.