The variable frequency heating method of the Gachn group valve bag bag making machine can adjust the heating power according to different heating requirements, thereby achieving more precise temperature control and more efficient energy utilization.

Product name :

Automatic Block Bottom Valve Bag Machine adstar bag all-in-oneItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsAutomatic Block Bottom Valve Bag Machine adstar bag all-in-one

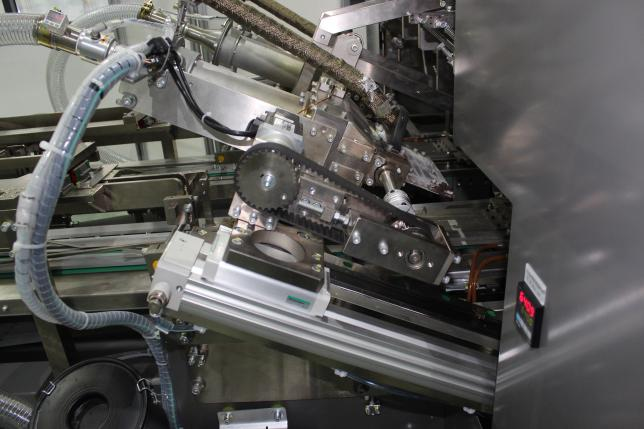

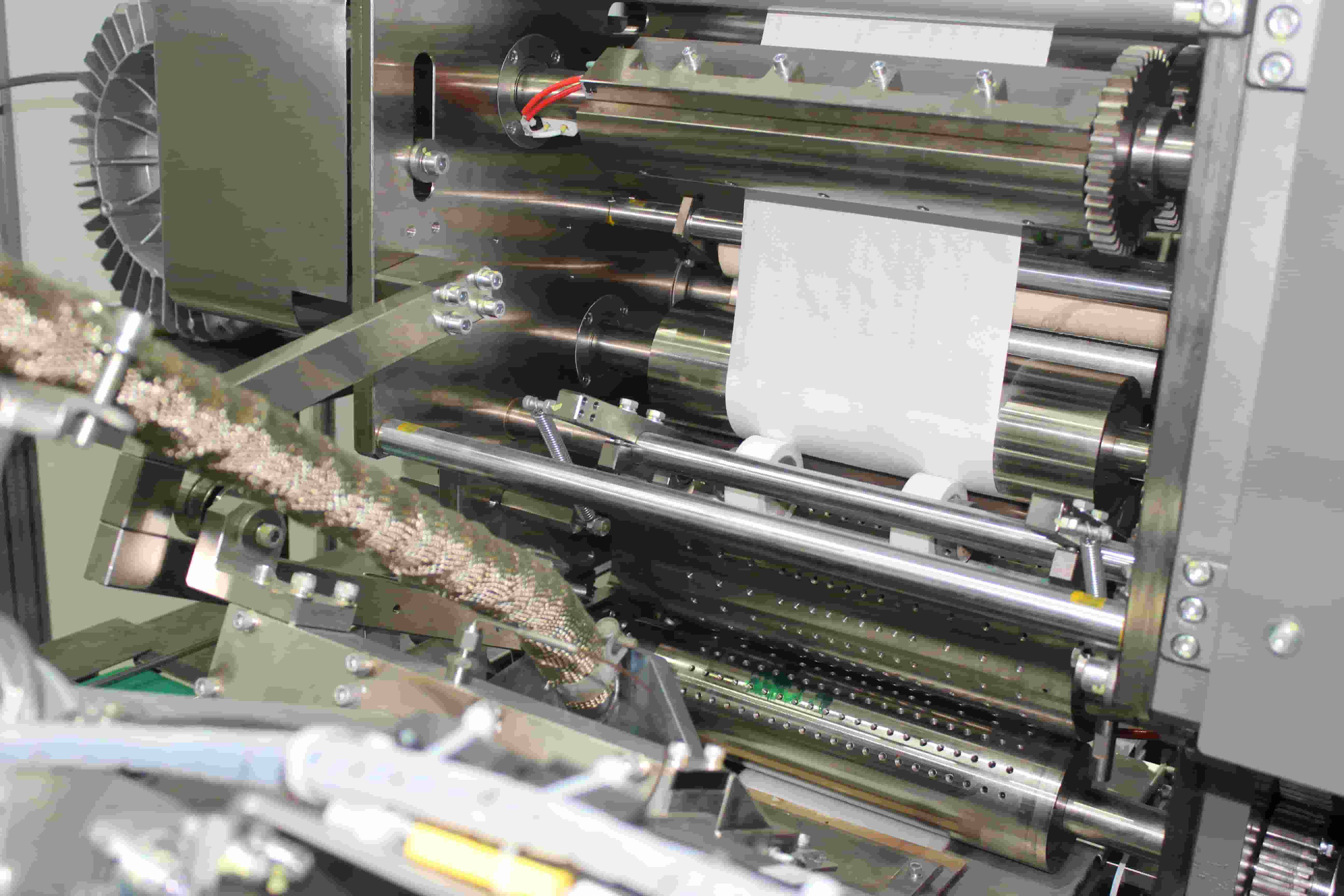

In the application of hot air guns in the bag making and feeding process of modern valve bag making machines and their possible performance improvement, bottom sticker heat sealing is a very important part of valve bag making machines. In the current bag making machine market, speed and stability are unavoidable topics, and heat sealing is a very critical part of it.

The core and importance of the heat sealing system

The hot air gun and hot air system of the bag making machine often determine the production speed of the valve bag making machine. Through the continuous upgrading of technology, Gachn group has been able to reach a production speed of 140pcs/min.

the heating efficiency, so that some bag production equipment can reach 150pcs/min. However, when ensuring the increase in the production of 150pcs/min bags, the stability of the valve bags produced is greatly reduced during the production process, resulting in problems with the heat sealing quality. And it is impossible to ensure the continuous production of 150pcs/min.

Why does this happen?

In the market, except for the automatic valve sack making machine Manufacturing companies Gachn group valve bags, the common method of increasing the power is to improve the performance of the hot air gun. Since other brands use traditional mechanical hot air guns, the temperature control cannot achieve a uniform and stable effect. Only by increasing the power of the heating element, the output temperature and air volume of the hot air gun can be increased to meet higher heating requirements.

However, it should be noted that increasing the power will also bring higher energy consumption and greater noise and greatly reduce the life of wearing parts. In addition, the larger output will bring a greater burden to the production workers. The workers will not have time to inspect the quality, resulting in a higher defective rate. In actual production, the faster heating speed will also affect the quality of the valve bag itself, and the negative impact of the product may cause the valve bag: broken bags, loose bottom stickers and other problems. In order to improve production efficiency and the stability of bottom sticker adhesion, Gachn group has designed a heat sealing system and AI visual inspection system that are different from the market.

Gachn group heating method

The variable frequency heating method of the Gachn group valve bag bag making machine can adjust the heating power according to different heating requirements, thereby achieving more precise temperature control and more efficient energy utilization. In the process of bag making and feeding, if different temperatures need to be adjusted according to different speeds, the variable frequency heating method may be a good choice. This heating method can ensure sufficient heating power when feeding at high speed, while reducing energy consumption and temperature fluctuations when feeding at low speed.

The use of variable frequency heating also depends on the design of the hot air gun and the technical strength of the manufacturer. Among the hot air guns currently on the market, only Gachn group is equipped with this function, while some low-end or economical products may not have it.

Advantages of Gachn group valve bag bag making machine in heat sealing technology

Uniquely designed heat sealing system: automatic valve sack making machine Producer Gachn group integrates optimized air duct structure through exclusive heat sealing technology to ensure uniform blowing and precise temperature control, thereby improving the quality of heat sealing joints. The specially designed adjustable blowing nozzle has a width adjustment accuracy of up to 1 mm and can be flexibly adjusted without interrupting production, greatly enhancing production flexibility and efficiency.

Independent control of servo motor: The heat sealing system uses advanced servo motors for independent control, making the operation more intelligent. Users can easily adjust the temperature of the heat sealing gun by simply entering the required parameters on the touch screen, and can complete the fine-tuning of the bonding temperature of the valve sticker and bottom sticker materials without stopping the machine. This feature not only simplifies the operation process, but also significantly improves the response speed and flexibility of the production line.

Material handling optimization: In view of the problem of easy corner folding due to the transfer of the elastic edge of the material, we have developed a unique solution to effectively avoid quality problems such as unstable overlap and loose heat sealing welding of valve bags caused by the elastic edge.

AI visual inspection: automatic valve sack making machine Supplier Gachn group can greatly improve the efficiency of manual inspection by equipping AI visual inspection, and AI can detect loopholes in the folded part of the bottom of the heat sealing welding that cannot be detected manually. Reducing the quality problems caused by the negligence of manual picking of bags not only builds a good reputation for the company but also reduces costs for the company.

In summary, using Gachn group valve bags can not only achieve high-speed production speed, but also Gachn group pays more attention to the stability of the valve bags produced, aiming to provide you with higher quality valve bags.

To this end, our innovative technology has not only promoted the technological progress of the packaging industry in continuous innovation, but also brought tangible economic benefits and competitive advantages to customers. Through efficient, stable and flexible production solutions, we are committed to becoming a long-term partner trusted by customers and jointly creating a better future.