Gachn group woven bag air flow tester GC-346-4 is a high-precision testing equipment designed for the packaging bag industry, integrating air permeability, pressure resistance and flow test functions.

Product name :

Air flow tester for valve bag produtionItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsAir flow tester for valve bag prodution

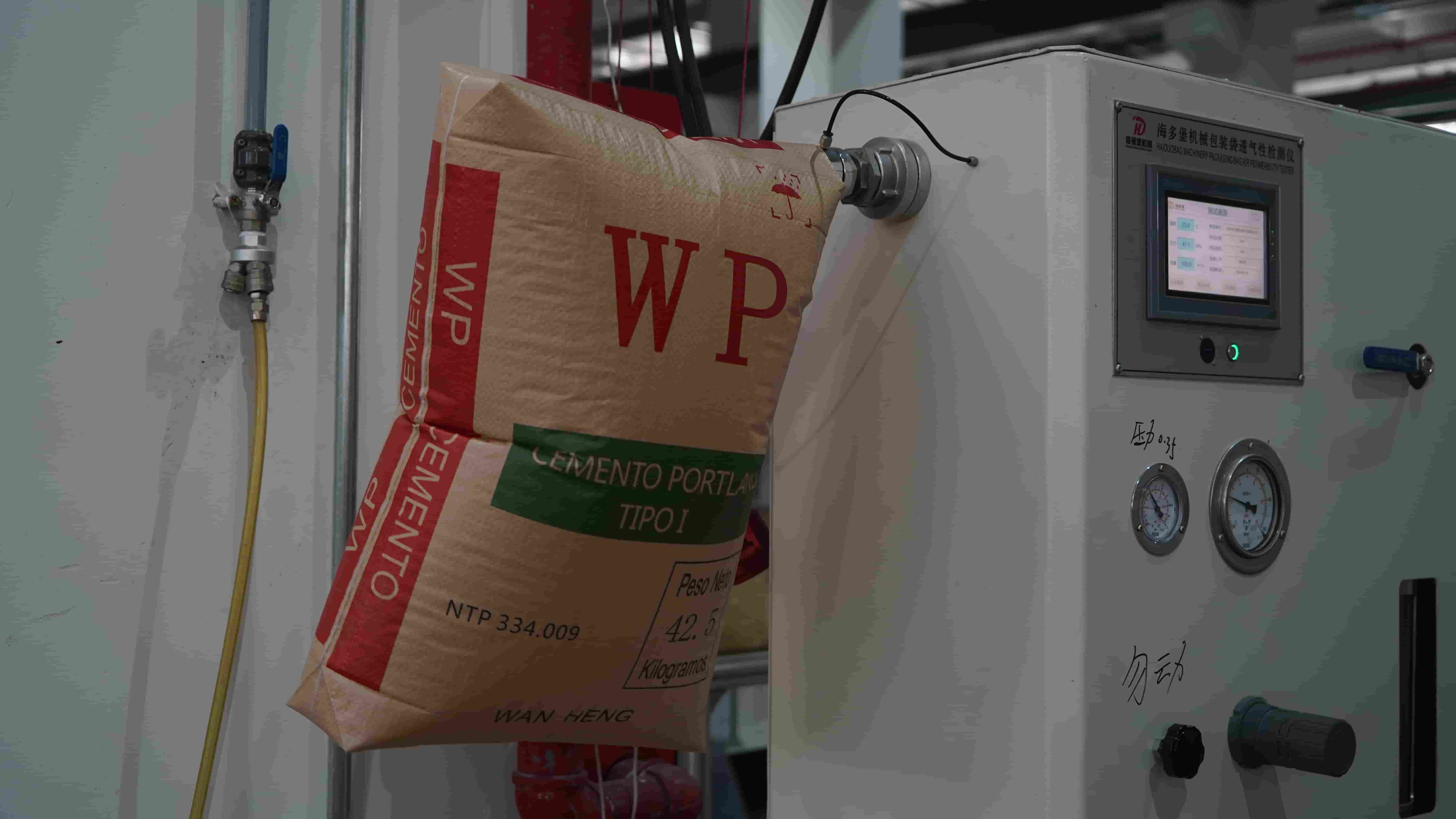

Gachn group woven bag air flow tester GC-346-4 is a high-precision testing equipment designed for the packaging bag industry, integrating air permeability, pressure resistance and flow test functions. Air flow bench tester supports comprehensive performance evaluation of various packaging materials such as heat-sealed valve bags, suture valve bags, and paper valve bags. Through intelligent operation and real-time data feedback, it helps enterprises optimize production processes, ensure product quality, and meet international standards such as GB/T.

Core advantages

Multi-function detection mode

Constant pressure detection: Precisely control the pressure range (0-100Kpa, accuracy 0.01Kpa), test the air permeability and fan speed of packaging bags.

Constant speed detection: Stabilize the fan speed (0-2800r/min), and analyze the flow (0-220m³/h) and pressure value in real time.

Strength detection: Verify the strength range of processes such as heat sealing, bonding, and sutures to ensure packaging durability.

Intelligent operation experience

One-touch operation: equipped with a 7-inch touch screen, real-time display of speed, flow, pressure and other data, intuitive presentation of test curves and results.

Multiple parameter storage: supports 30 sets of workpiece parameter presets, quickly switches to different product testing requirements, and improves efficiency.

Convenient data management: The test report can be exported to a USB flash drive (Excel format), and historical data is saved for up to 90 days for easy traceability and analysis.

Safe and reliable design

Dual protection mechanism: mechanical and electrical safety interlock design, equipped with access protection and emergency stop button to ensure safe operation.

Strict operating specifications: supports Lockout/Tag-out procedures to ensure that the equipment is powered off during maintenance to avoid unexpected risks.

Environmental adaptability: wide voltage input (220V±10%), stable gas source pressure (0.5-0.7Mpa), adaptable to complex working conditions.

Technical parameters at a glance

| Item | Parameters |

| Power supply voltage | 220V±10% 50/60Hz |

| Rated power | 3.0KW |

| Air source pressure | 0.5-0.7Mpa |

| Fan speed | 0-2800r/min |

| Flow detection range | 0-220m³/h (accuracy 0.1m³/h) |

| Constant pressure range | 0-100Kpa (accuracy 0.01Kpa) |

| Strength pressure range | 0-1Mpa (accuracy 0.1Kpa) |

| Equipment size | 1100mm×800mm×1320mm |

Operation highlights

One-button start, efficient detection

Select the test mode (constant pressure/constant speed/intensity) through the touch screen, start air mass flow measurement tester after setting the parameters, and automatically complete the whole process of inflation, detection, and data judgment.

Real-time alarm for abnormal data (buzzer prompt + screen warning) to ensure timely handling of problems.

Flexible parameter configuration

Users can customize pressure, flow, and speed thresholds to adapt to various detection standards.

Support password lock function to prevent unauthorized parameter modification and ensure data reliability.

Pressure cycle test

Simulate actual use scenarios, set the number of cycles (default 2 times) and pressure value (default 120Kpa) to verify the long-term pressure resistance of the packaging bag.

Safety and maintenance

Must read before operation: Air flow test machine must be placed in a dry and ventilated environment, away from flammable materials; keep it level during transportation to avoid tipping over.

Professional maintenance: Only certified personnel are allowed to inspect and repair. Before maintenance, the power supply must be cut off and the plug must be unplugged, and insulating tools must be used.

Regular calibration: It is recommended to check the sensor accuracy and air path sealing every quarter to ensure the accuracy of the test results.

Applicable scenarios

Packaging manufacturers: Raw material incoming inspection and finished product outgoing quality control.

Quality inspection agencies: Perform GB/T, ISO and other standard certification tests.

R&D laboratories: New material permeability research, process optimization data support.