The full servo valve bag making machine provided by Gachn Group is of great significance in the transportation and storage of gypsum, and can ensure the safe, efficient and stable transportation and storage of gypsum.

Product name :

Adstar Bag Production Line Adstar Making MachineItem No :

FK008-IIOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

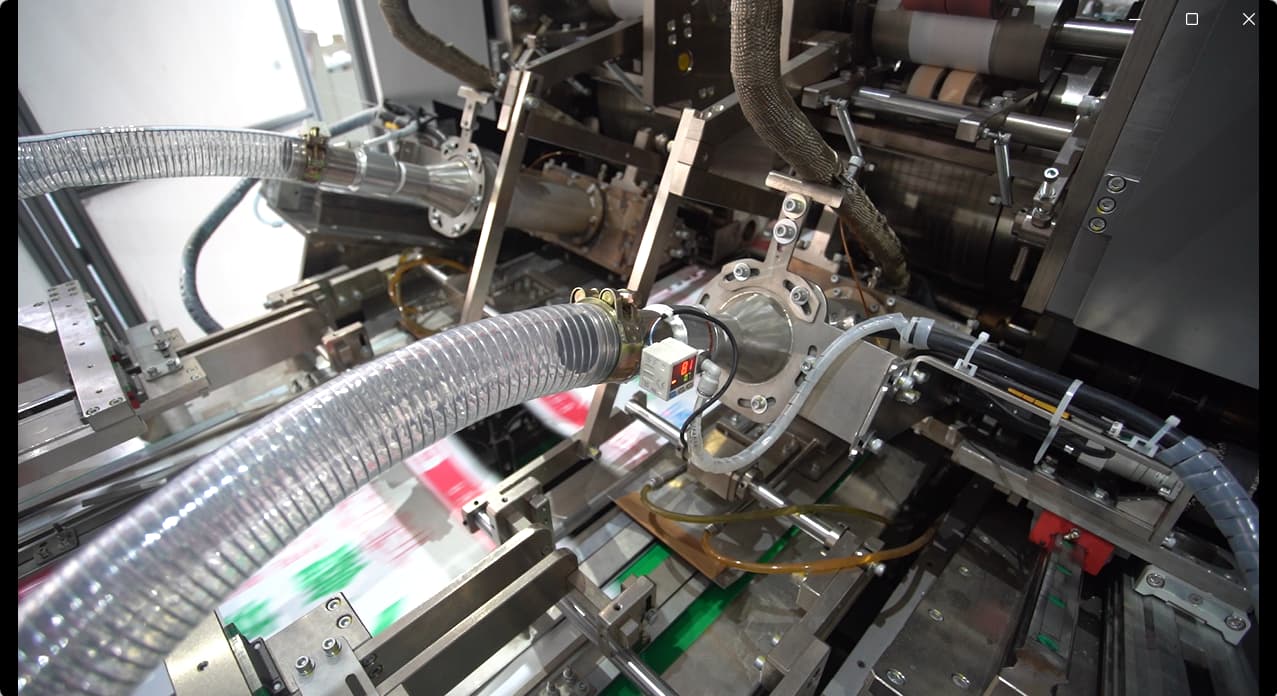

3 monthsAdstar Bag Production Line Adstar Making Machine

This article is to introduce the chemical composition, uses, storage precautions of gypsum, and the advantages of the full servo valve bag making machine Manufacturing companies provided by Gachn Group in the transportation and storage of gypsum.

Gypsum is a hydrate mainly composed of calcium sulfate (CaSO4), which has a wide range of applications in industry and construction. As an industrial material, gypsum can be used in cement retarder, sulfuric acid production, etc.; as a construction material, gypsum is widely used in gypsum building products, model making, etc. In addition, gypsum can also be used as a medical food additive and a filler for paper and paint.

Application of full servo valve bag making machine in gypsum transportation and storage

During the current transportation process, because gypsum is easily affected by moisture and absorbs moisture, and it condenses and hardens quickly, special attention must be paid to avoiding moisture during transportation and storage. The strength of gypsum stored for a long time will also decrease, so reasonable storage conditions are crucial to maintain the performance of gypsum. The full servo valve bag making machine Producer currently provided by Gachn Group

Using Gachn Group valve bag making machine to produce valve bags has the following significant advantages in the transportation and storage of gypsum:

Long valve mouth design: The valve bags produced by Gachn Group's valve sack making machine Supplier have the function of being attached to the extended valve mouth. After canning, they can be sealed with a sealing machine to achieve complete sealing and effectively prevent gypsum from leaking during transportation.

Valve sticker and bottom sticker conveying device: The valve sticker mechanism and the bottom sticker mechanism are equipped with an automatic correction system, and the sticker is accurate. An anti-winding device and a color mark movement tracking system are added to ensure the accuracy of the positioning of the valve sticker at the bottom of the bag, which greatly improves the accuracy of the valve sticker positioning. This ensures that the bag will not be broken due to inaccurate positioning during filling and transportation.

Welding device: The bottom sticker also adopts a heat sealing welding system. It uses unique technology to achieve uniform air blowing and constant size. It adopts a constant temperature control system to achieve stable and reliable welding temperature, which can improve the welding firmness. The suction roller holes with smaller spacing can effectively prevent the patch from warping, weak welding, loose bottom patch caused by unstable welding, bottom patch gap and other problems, which will affect the quality of the gypsum transportation process.

Precise patching and correction device: It is equipped with a correction device and an anti-winding device, as well as a color mark movement tracking system to ensure accurate positioning during material transportation and to ensure that the bag body will not be skewed and the bottom patch will not be positioned inaccurately during the bag making process.

Bag mouth pressing technology: The collector valve bag making machine has a belt conveyor device, which can further press the bag mouth to ensure that the opening does not rebound after forming and enhance the sealing and stability of the bag.

Constant temperature control system: The constant temperature control system is adopted to achieve stable and reliable welding temperature, improve the welding firmness, and prevent the valve bag from being damaged during transportation and storage.

Prevent patch warping: The suction roller holes with smaller spacing are used to effectively prevent patch warping and improve the overall quality and aesthetics of the bag.

To sum up, the full servo valve bag making machine provided by Gachn Group is of great significance in the transportation and storage of gypsum, and can ensure the safe, efficient and stable transportation and storage of gypsum.