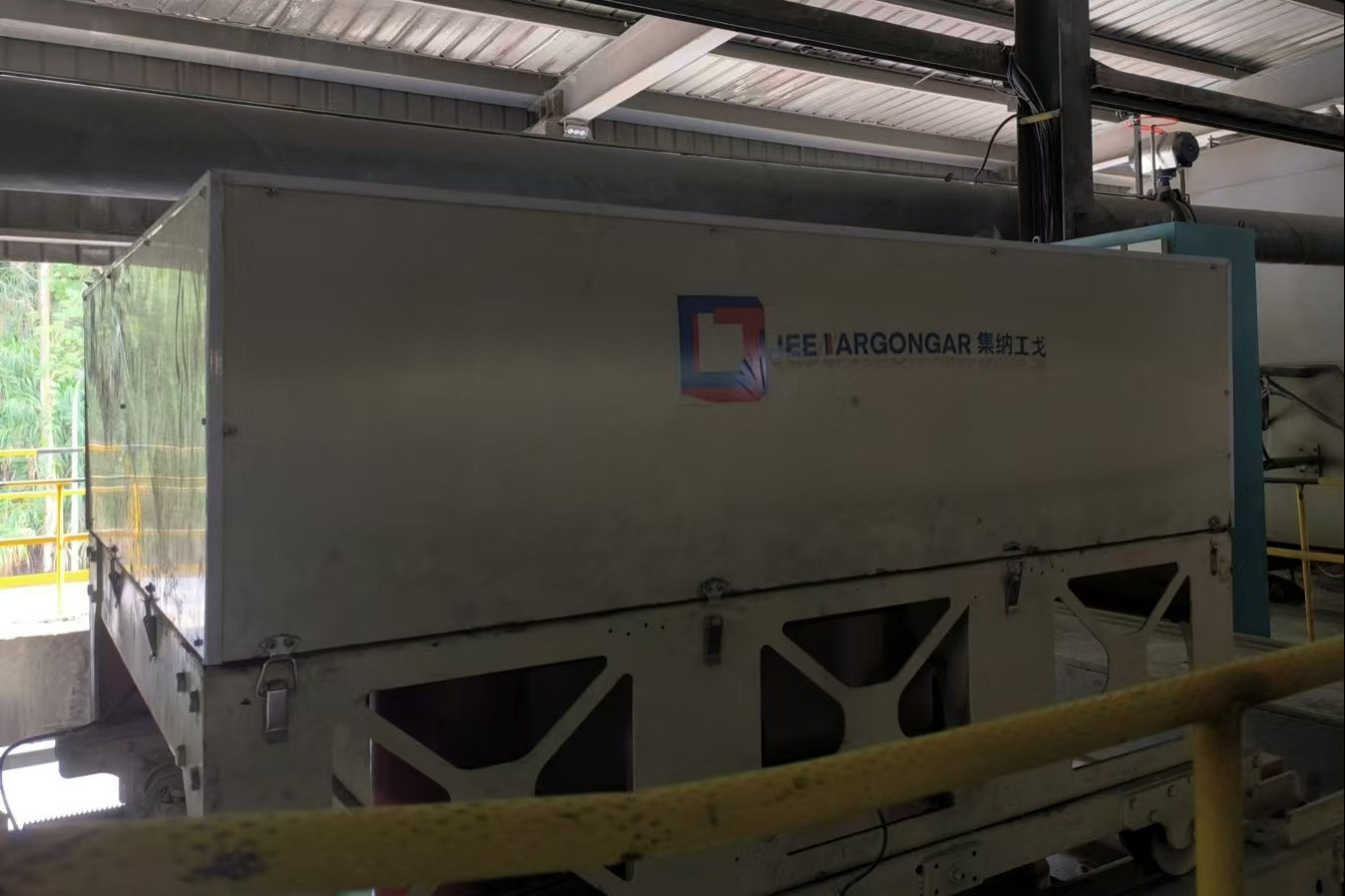

Bagged Cement Palletizing And Loading Machine Manufacturer

GACHN -JEENAR bagged cement palletizing and loading machine is Wide adaptability: Easily handles all types of trucks, including high-rail models.

Product name :

bagged cement palletizing and loading machine ManufacturerOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

Xiamen,ChinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 mouthsbagged cement palletizing and loading machine Manufacturer

In modern cement loading and manufacturing, loading and unloading is a key step in the supply chain. Traditional manual loading and unloading methods are not only inefficient, but also have many safety hazards and cost issues. With the rapid development of automation technology, bagged cement palletizing and loading machine Production Supplier are gradually replacing traditional manual loading and unloading methods. Traditional manual loading relies on a large number of workers, which is not only labor-intensive and inefficient, but also prone to damage and scattering of goods due to human factors, increasing the cost of subsequent processing. Although forklift loading has improved efficiency to a certain extent, it is limited by the operator's skill level and blind spots, and there is still a risk of collision, posing a threat to the safety of goods and personnel. In addition, both methods are difficult to achieve efficient and accurate loading effects, affecting the overall logistics efficiency.

After Gachn-jeenar's research and unremitting efforts to develop, we have now realized intelligent automated unmanned loading, which can be applied to a variety of models, and no personnel are required on site. Different from the traditional cement loading method, the use of bagged cement palletizing and loading machine Exporters can greatly avoid skin damage caused by contact with cement, and greatly avoid personal injury caused by forklifts to humans.

This loading method can save loading labor, improve loading efficiency, and reduce the damage to the respiratory tract of workers caused by cement spillage during handling and loading and unloading. Each device can save 4 manual labor for the factory and increase the loading rate by up to 95%.

The equipment integrates functions such as logistics distribution, industrial robots, vehicle contour detection and cement stacking algorithm software

bagged cement palletizing and loading machine Traders

1. The size and position of the vehicle are automatically measured by radar three-dimensional scanning, and the position deviation is alarmed.

2. The system adopts an advanced self-developed control system to automatically calculate and control the number of stacking each time.

3. The system uses a six-axis manipulator as an actuator with a very high degree of freedom. It is suitable for a wide range of loading models, and the shape of the stacking can also be freely selected.

4. The system moves by directly landing on the ground rail, so it can be used for loading extra-long vehicles.

5. The drive device of the system is driven by an absolute servo motor acceleration and reduction gear, with precise front and rear running position control and sensitive braking. The entire drive device is durable.

6. After setting the loading parameters, one-button start of fully automatic loading is achieved; in the case of normal loading without alarm, the loading completion mechanism automatically returns to the initial position.

7. When a fault occurs during the loading process, the system can automatically pause, and the cause of the fault can be checked through the touch screen. After eliminating the fault, the system can continue loading.

8. The system can display various status, fault, and counting information through the touch screen.