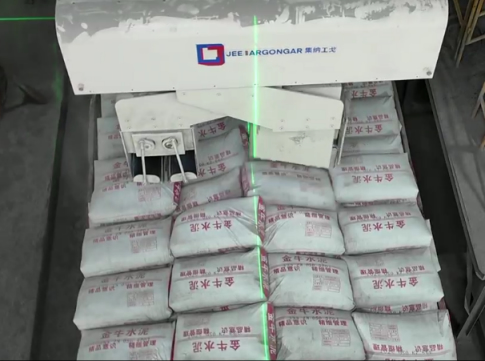

3D Scanning of Automatic bagged cement loading system for All Vehicle Types.

Product name :

Automatic Bagged Cement Loading System ExportersOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

Xiamen,ChinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 mouthsAutomatic Bagged Cement Loading System Exporters

Why we recommend you to be the agent of Gachn Automatic bagged cement palletizing and loading machine Production Supplier?

At present, the development of the world's cement industry has gradually moved towards unmanned, standardized and automated directions. In the cement production industry, in the process of cement automatic loading, the traditional manual bagging action is complex, interlocking, and requires precision. The cement bag assembly line is difficult to control, and the loading efficiency is slow. Xiamen Gachn has launched a bagged cement palletizing and loading machine Manufacturer Gachn-JEENAR to address this pain point.

Being the agent of Gachn cement loading machine is your best choice. We bring you the following advantages:

VS

VS

Performance that takes precedence over the market

Gachn-Jeenar cement loader can bring you and your customers a difference from traditional manual loading. One loader can meet the fastest loading speed of 120T/H. Secondly, the system control program is an effective way to improve the efficiency of the cement automatic loader. Gachn-Jeenar Co., Ltd. has optimized and upgraded the original 2.0 to 3.0 system control program, optimized the process, reduced unnecessary process control, increased safety protection, and brought customers safer production actions. We have a deep understanding of the cement production process to ensure that the automatic loader is closely coordinated with the entire production process to reduce unnecessary waiting time and waste. In order to adapt to different models and model different carriage sizes to improve the utilization rate of carriages, and guide vehicles to park at designated locations, the cement automatic loader adopts the centerline deviation automatic correction design. When the loading vehicle centerline deviates within 200mm, the equipment can automatically correct the deviation to ensure that the code package is correct and neat. Solve the problem of automatic loading of customers when the length of the loading lane is limited for overlong vehicles.

High-quality products can give you a huge advantage in market competition, gain customer recognition and trust, and increase your market share.

2. Best service

We apply the self-developed bagged cement Separate packaging technology and bagged cement special Separate packaging machine, and design a patented product - bagged cement special packing machine, which can make the process smoother, operation and maintenance more convenient, and the failure rate is the lowest, which greatly solves the technical difficulty of acting as an agent for our products and reduces customers' demand for after-sales service.

We support you to provide a responsible after-sales team to your customers and strengthen the cooperation between you and your customers.

3. Quality assurance

We use international brand accessories, improve costs, ensure quality and provide you and your customers with high-quality products.

At present, our equipment has been used by Chinese cement customers and has met customer needs, deeply meeting customers' requirements for the functions of cement loaders, and has been well received by customers.

|

NO. |

NAME |

Brand |

|

1 |

HMI |

Schneider |

|

2 |

Programmable controller |

Schneider |

|

3 |

Servo Motor Servo controller |

Schneider |

|

4 |

Reducer |

SHIMPO/TRANSTECNO |

|

5 |

laser radar |

DuGe 3D radar+ifm laser ranging |

|

6 |

Electrical control components |

Schneider |

|

7 |

Sensor |

Omron photoelectric PNP+Hanxi ultrasonic sensor switch quantity PNP |