With the booming global construction industry, the demand for cement continues to rise, and traditional packaging methods can no longer meet the needs of efficient and precise modern production.

Product name :

Spirit-controlled bagging machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsSpirit-controlled bagging machine

With the booming global construction industry, the demand for cement continues to rise, and traditional packaging methods can no longer meet the needs of efficient and precise modern production. According to authoritative forecasts, the global cement market size will exceed US$46.85 billion in 2029, and the cement sack insertion machine manufature in china, as a core production equipment, is becoming a key engine for industry upgrading.

Gachn group cement bag inserter, with innovative technology and automated design, helps companies achieve a leap in packaging efficiency, save up to 30% of labor and material costs, and reshape productivity with intelligent technology!

Core advantages: technology empowerment, defining industry benchmarks

✅ Efficient and stable, excellent performance

The patented bag grabbing and pressing structure (as shown in Figure 1) is used to accurately control the packaging process, increase the speed by 40%, and reduce the failure rate to the lowest in the industry.

Modular front mechanism design (as shown in Figure 2) is easy to maintain, extends the service life by 50%, and adapts to high-intensity continuous operations.

✅ Intelligent transformation, promising future

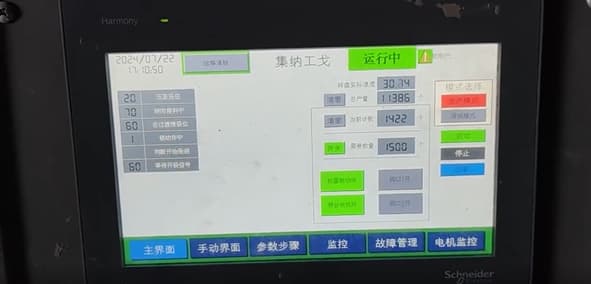

Integrate AI algorithms and IoT technology, monitor production data in real time, automatically optimize parameters, and realize "unmanned" intelligent management.

Support customized functions to meet the packaging needs of different specifications, helping companies to flexibly respond to market changes.

✅ Quality certification, global trust

Passed ISO international quality certification, packaging accuracy reaches 99.9%, significantly improving product appearance consistency and empowering the brand's high-end image (as shown in Figure 3).

The service network covers 30+ countries, with 24-hour technical response, providing worry-free protection for global customers.

Investment value: Four dimensions, locking in long-term returns

1️⃣ Broad market space

The global urbanization process is accelerating, housing and infrastructure demand is surging, and the annual growth rate of the cement industry is stable at more than 5%. As a pouch spout inserter machine manufature in china, the market scale of the bag inserter will continue to expand.

2️⃣ International trade dividends

With the deepening of the "Belt and Road" and cross-border cooperation, there is a strong demand for overseas cement production capacity construction. Gachn gourp equipment has become the first choice for global customers with its high cost-effectiveness.

3️⃣ Competitiveness breakthrough

Industry competition is intensifying, and only technology leaders can win. Gachn gourp focuses on innovation and research and development to help companies reduce costs and increase efficiency and create differentiated competitiveness.

4️⃣ Brand premium upgrade

Standardized and intelligent packaging greatly improves product image, seizes consumers' minds, and helps brand value leap.

2. Key advantages and parameters

| 模块 | 技术特点 | 数据 / 效果 | Module | Technical features | Data/Effect |

| 开袋机构 | V 型组合吸盘 | 开口完整可靠,避免漏料 | Bag opening mechanism | V-shaped combined suction cup | The opening is complete and reliable, avoiding material leakage |

| 整理平台 | 自动整平袋子 | 提升后续码垛效率 | Arrangement platform | Automatically flattens bags | Improving the efficiency of subsequent palletizing |

| 多功能袋仓 | 可容纳 720 个袋子 | 满仓可持续供料约 18 分钟 | Multi-function bag bin | Can hold 720 bags | The continuous feeding of materials in a full warehouse can last for about 18 minutes |

| 低位放袋 | 设备自动移动取袋 | 减少工人搬运动作,降低劳动强度 | Low-level bag placement | Equipment automatically moves to take bags | Reducing the carrying movements of workers and reducing labor intensity |

3. Value enhancement

·Labor cost: Reduce the number of labor and reduce employment costs.

·Efficiency: Full process automation to improve processing speed.

·Safety: Reduce manual contact with dangerous links and improve operational safety.

Key questions and answers

Technical innovation

Q: How does the Gachn group bag insertion mechanism ensure the integrity of the bag opening?

A: The V-shaped combined suction cup mechanism is used to combine the mechanical structure with negative pressure adsorption to ensure that the bag mouth is fully opened and undamaged.

Efficiency optimization

Q: How does the design of the multi-functional bag bin improve production continuity?

A: The full bin capacity of 720 bags can support 18 minutes of continuous feeding. The operator can use the gap to handle other tasks and reduce downtime waiting time.

Operation convenience

Q: What are the advantages of the low-level bag placement method of the Gachn group bag insertion machine?

A: The equipment automatically moves into the bag bin to retrieve bags, which avoids workers from bending over or carrying bags frequently, thus reducing physical exertion and operating difficulty.