The gachn group Automatic cement bag insertion machine is a mechanical device designed for the automatic loading of cement bags, widely used in cement production lines and storage facilities. It adopts advanced automation technology to quickly and accurately assist to complete the bagging process.

Product name :

Automatic cement bag insertion machineItem No :

JGCD-001Order(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

XIAMEN,CHINAShipping Port :

XIAMEN or Or according to your needsLead Time :

3 mouthsAutomatic cement bag insertion machine

The JGCD-001 Automatic cement bag insertion machine realizes the full automation of the packaging process, realizes automation instead of manual labor, and reduces the harm of cement dust to the human body. With high-precision servo motor control, the machine achieves a bag insertion success rate of over 99%, significantly increasing packaging productivity.

Automatic cement bag delivery machine is a mechanical device designed for the automatic loading of cement bags, widely used in cement production lines and storage facilities. It adopts advanced automation technology to quickly and accurately assist to complete the bagging process.

Automatic cement bag inserting machine typically consists of the following main components:

1. Conveying system : The Cement Bag Inserter is equipped with a conveying system that transports sealed cement bags into the machine. This system can use conveyor belts or rollers to ensure the smooth entry of bags into the insertion area.

2. Bag insertion area : The bag insertion area is the core part of the Cement Bag Inserter. This area usually includes a robotic arm or a clamp to grab the cement bag, open the bag, and accurately insert the bag mouth into the filling spout. The robotic arm is highly flexible, accommodating cement bags of different sizes and shapes.

3. Automatic control system : The Cement Bag Inserter features an advanced automated control system that monitors and regulates the machine’s operation. This automation enhances the equipment's stability and operational efficiency.

The Cement Bag Inserter features an advanced automated control system that monitors and regulates the machine’s operation. This automation enhances the equipment's stability and operational efficiency.

Features:

• Automatic Bag Sorting : Equipped with an intelligent bag sorting system to ensure neat bag placement and improve the bag insertion success rate.

• Bag Storage : The bag storage capacity can be customized according to customer requirements, providing flexible and convenient bag placement.

• High Success Rate : Achieves a bag insertion success rate of ≥99%.· User-Friendly Operation: Simple operation with an ergonomic design.

Specifications:

• Basic Dimensions of the Bag Inserter : Comes with a 4-meter-long bag storage platform (capable of holding 500 bags); Length × Width × Height: 6900×4700×2050(mm).

• Main Machine Dimensions : L5.5m × W3.0m × H2.2m (subject to final layout), equipped with height adjustment devices at the base.

• Total Machine Weight : Approximately 2300KG (Power supply: 3Ph380Vac ±5%, 50HZ, three-phase five-wire system, CE standard).

• Total Power : Approximately 10KW.

• Air Supply : Pressure ≥0.6MPA, working pressure ≥0.5MPA (the supplier provides a 20L air storage tank; the buyer needs to provide the air source).

• Customizable Bag Storage Platform : The length of the bag storage platform can be customized according to customer requirements.

Components and parts configuration:

Electrical components

| Name | Brand Model |

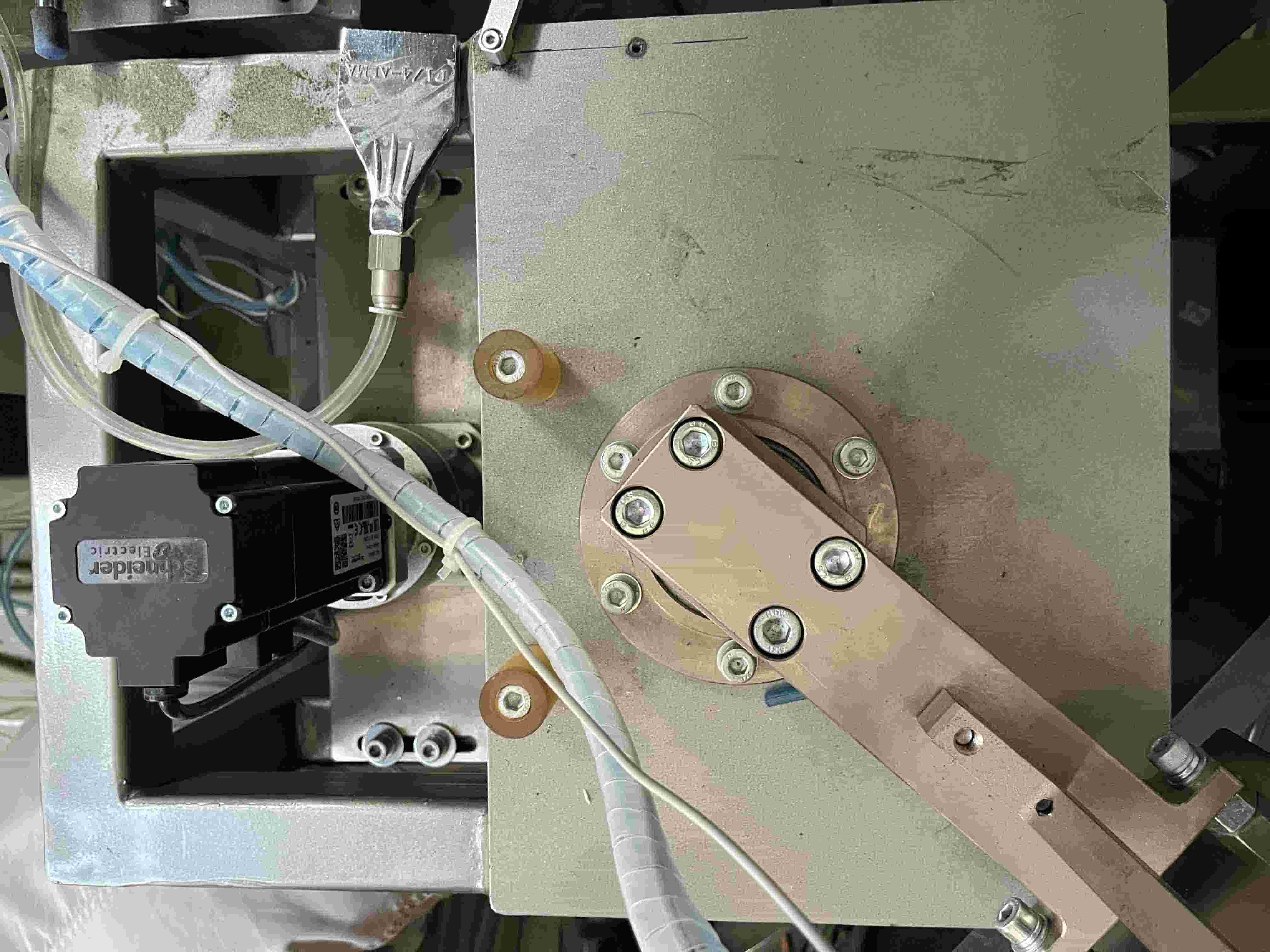

| Buttons, circuit breakers, contactors, relays, switching power supplies | Schneider, Weidmuller, Omron, Mean Well |

| Logic control, motion control | Schneider |

| Sensor | Panasonic, SICK |

| Servo Drives | Schneider |

| Servo Motor | Schneider |

| Human Machine Interface | Schneider |

| Safety products (safety relays, safety door locks, etc.) | Omron |

Mechanical components

| Name | Brand Model |

| Servo planetary reducer | SHIMPO (Japanese) |

| Couplings | KTR (Germany) |

| Pneumatic solenoid valve | AirTac, SMC, CKD |

| cylinder | AirTac, SMC, CKD |

| Rolling bearings | AirTac, SMC, CKD |

| Spherical plain bearings | IKO (Japanese) |

| Linear bearings, guide rails | HIWIN (Taiwan) |

| Air pump | Gree |

Bag Pushing Component

• Equipped with a bag placement platform with three-way positioning and a bag pushing component for easy manual bag loading.

• The platform's positioning and bag pushing location are adjustable to accommodate different bag sizes.

• The bag pushing mechanism ensures stable and accurate insertion of the stack of bag into the bag box.

Bag Pulling Component

• The bag pulling component features a unique design, ensuring precise transfer of bags from the bag box to the sorting component.

• A transition area between the bag box and sorting component ensures smooth movement of the stack of bag.

Bag Sorting Component

• The bag sorting component includes functions for controlling the lifting of the bag stack, shaking, and tapping the bags.

• The lifting and bag holding assembly catches the bag stack pulled from the bag box.

• The upper and lower vibration components reduce friction between the bags, while the tapping component arranges the edges of the bag stack, improving the success rate of subsequent bag opening and insertion.

Bag Steering and Feeding Component

• The bag steering and feeding component is a rotating and lifting bracket driven by a servo motor and cylinder, which transfers the bag stack from the sorting component to the bag opening transition platform.

• The secondary bag pushing component uses servo-driven cylinders to push the bag stack from the transition platform to the bag opening station.

Bag Opening Component

• The bag opening component includes a bag opening workstation, motion control assembly, bag opening suction cups and air system, and a bag opening hook assembly.

• It enables vertical control of the suction cups and hooks, adapting to different bag stack heights.

• The bag opening angle self-adjusts to the surface curvature of the bag, ensuring stable suction throughout the opening process.

• The suction system provides high negative pressure and displays real-time vacuum pressure during the bag opening process.

Bag Insertion Component

• The bag insertion component includes a bag gripping assembly.

• Motor-driven, the gripping assembly moves to keep the packaging bag open and accurately positions it onto the filling machine’s box, ensuring smooth, precise, and reliable operation while maintaining the integrity of the bag film.

• The motion curve can be adjusted when the product packaging specifications change.