In the field of cement production, traditional packaging methods are facing the dual challenges of efficiency and environmental protection.

Product name :

Smart Bagging MasterItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

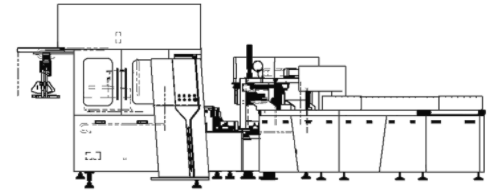

3 monthsSmart Bagging Master

In the field of cement production, traditional packaging methods are facing the dual challenges of efficiency and environmental protection. With years of technological accumulation, Gachn group has launched a new generation of cement sack insertion intelligent equipment, reshaping industry standards with intelligent technology, and creating a green and efficient modern production model for enterprises.

1. Intelligent core, precise innovation

Gachn group pouch spout inserter intelligent equipment adopts innovative grab-suction bag insertion technology, and realizes the full process automation of valve bag from storage to filling through the perfect collaboration of high-precision robotic arm and intelligent suction cup system. Its core advantages are:

・99.9% bag insertion success rate: breaking through the technical bottleneck of traditional manual and jet equipment

・2,400 bags/hour processing capacity: matching rotary packaging machine to achieve 120 tons/hour production capacity

・Millimeter-level positioning accuracy: ensuring seamless connection between the bag opening and the filling port

2. Double-effect protection Green production

Dust pollution solution

Through the sealed bag insertion structure and negative pressure dust suction system, dust leakage is reduced by more than 90%, eliminating occupational hazards such as silicosis from the source. The measured data shows:

・The dust concentration of raw materials has dropped to 1/5 of the national standard limit

・The contact with clinker dust has been reduced by 87%

・The annual dust emission has been reduced by about 300 tons

Noise control technology

The innovatively designed low-vibration mechanical structure and the soundproof cover reduce the noise value in the operating area to below 70dB, achieving:

・A single workstation can control 3-5 devices

・The operator keeps a safe distance from the equipment

・The risk of occupational noise exposure is reduced by 92%

III. Value upgrade, the choice for the future

・Cost optimization: save 80% of labor costs and reduce material loss by more than 5%

・Quality improvement: standardized filling error <±0.5kg

・Compliance guarantee: passed the EU CE certification and Chinese environmental protection standards

・Smart interconnection: support remote monitoring and data analysis to achieve preventive maintenance

Gachn group takes "technology empowers green manufacturing" as its mission and continues to promote the intelligent and environmentally friendly upgrade of the cement packaging industry. We provide full-cycle solutions from cement sack pouch spout inserter intelligent equipment customization, installation and commissioning to operation and maintenance services, helping companies to improve production efficiency while fulfilling their social responsibilities and building a sustainable future.