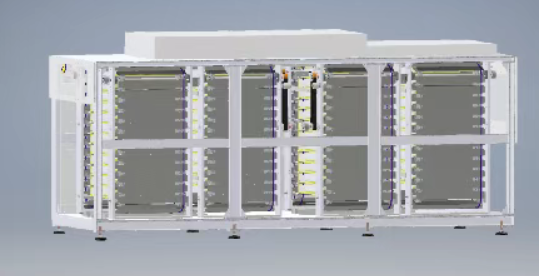

This equipment is an intelligent packaging solution designed for powdered/granular materials such as cement, coal powder, and fertilizer.

Product name :

Quick and stable multifunctional powder packing masterItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsQuick and stable multifunctional powder packing master

Intelligent bag inserter machine is a packaging solution designed for powdered/granular materials such as cement, coal powder, and fertilizer. It can realize the full process automation from automatic bag feeding, bag opening, bag insertion to sealing. Cement bag feeding machine adopts advanced mechatronics technology and can seamlessly connect with multi-mouth rotary cement packaging machines, helping enterprises to achieve intelligent upgrades in the packaging process with efficient and stable performance.

[Core Advantages]

1. Efficiency Revolution

· Complete high-speed packaging of up to 40 bags per minute, which is more than 5 times the efficiency of traditional manual labor

· Full process automation design to reduce waiting time in intermediate links

2. Cost optimization

· Replace a 4-person operation team to save labor costs

· Accurate measurement system error < 0.2%, eliminating material waste

3. Safety guarantee

· Eliminate the hidden dangers of work-related injuries caused by manual handling

· Closed working environment reduces dust pollution

4. Flexible adaptation

· Supports 25-50kg packaging bags of various specifications

· Compatible with packaging machine interfaces of different brands

[Technical Highlights]

Intelligent bag feeding system:

· Three-level buffer bag storage bin design to ensure the continuity of bag supply

· Servo-driven roller group to achieve 0.1mm level position control

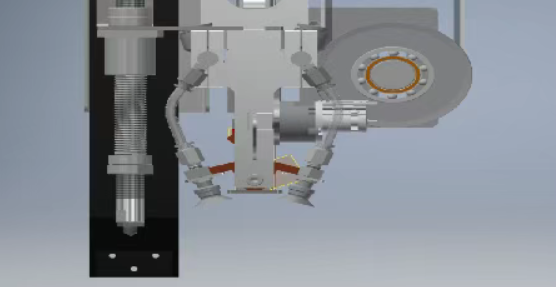

Intelligent bag insertion system:

· Six-axis robotic arm with visual positioning system

· Double-station alternating operation to ensure continuous operation of equipment

· Adaptive pressure adjustment bag clamping device

Intelligent control system:

· Industrial-grade PLC + Human-machine interface operation platform

·Real-time production data monitoring and fault warning

·Support MES system data docking

[Application scenarios]

·Cement production enterprise packaging line

·Building material powder processing enterprise

·Chemical raw material packaging workshop

·Grain processing and feed production industry

[Equipment composition]

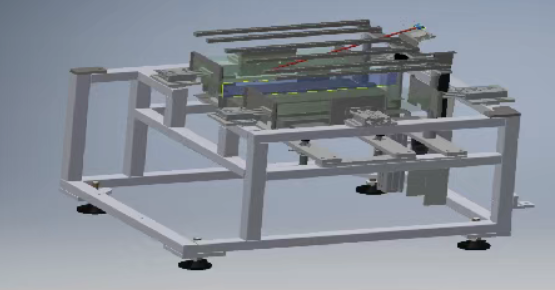

1. Intelligent bag feeding system: including bag storage bin, servo bag feeding roller, automatic bag sorting device

2. Six-axis bag insertion robot arm: equipped with high-precision force control sensor

3. Visual positioning system: achieve ±1mm level bag insertion accuracy

4. Synchronous follow-up mechanism: dynamically match the rotation speed of the packaging machine

5. Electrical control cabinet: integrated variable frequency speed regulation and intelligent control module

[Technical parameters]

·Applicable bag type: woven bag/paper bag/composite bag

·Packing speed: 2400 bags/hour (standard working conditions)

·Measuring accuracy: ±0.1kg

·Air source pressure: 0.5-0.7MPa

·Power supply requirement: 380V/50Hz

·Equipment weight: about 2.8 Tons

As a representative packaging cement bag delivery machine in the Industrial 4.0 era, Gachn group's bag inserter significantly improves production efficiency and reduces enterprise operating costs through intelligent design. We provide full-cycle services from equipment selection, installation and commissioning to after-sales maintenance to help customers achieve intelligent upgrades in the packaging process. Contact us now to get exclusive solutions