Intelligent and environmentally friendly cement bag inserting machine

In the traditional cement packaging process, manual bag insertion faces three core challenges

Product name :

Intelligent and environmentally friendly cement bag inserting machineItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsIntelligent and environmentally friendly cement bag inserting machine

In the traditional cement packaging process, manual bag insertion faces three core challenges:

1. Occupational health risks: long-term exposure to noise environments > 80dB and workplaces with dust concentrations exceeding 15mg/m³

2. Production efficiency bottleneck: The manual bag insertion speed is only 8-10 bags/minute, which restricts the efficiency of the entire production line

3. Environmental compliance pressure: unorganized dust emissions must be controlled below 0.5mg/m³, and traditional processes are difficult to meet the standards

[Solution]

Gachn group's intelligent and environmentally friendly cement bag insertion machine achieves industry pain point breakthroughs through three innovative systems:

I. Core technology architecture

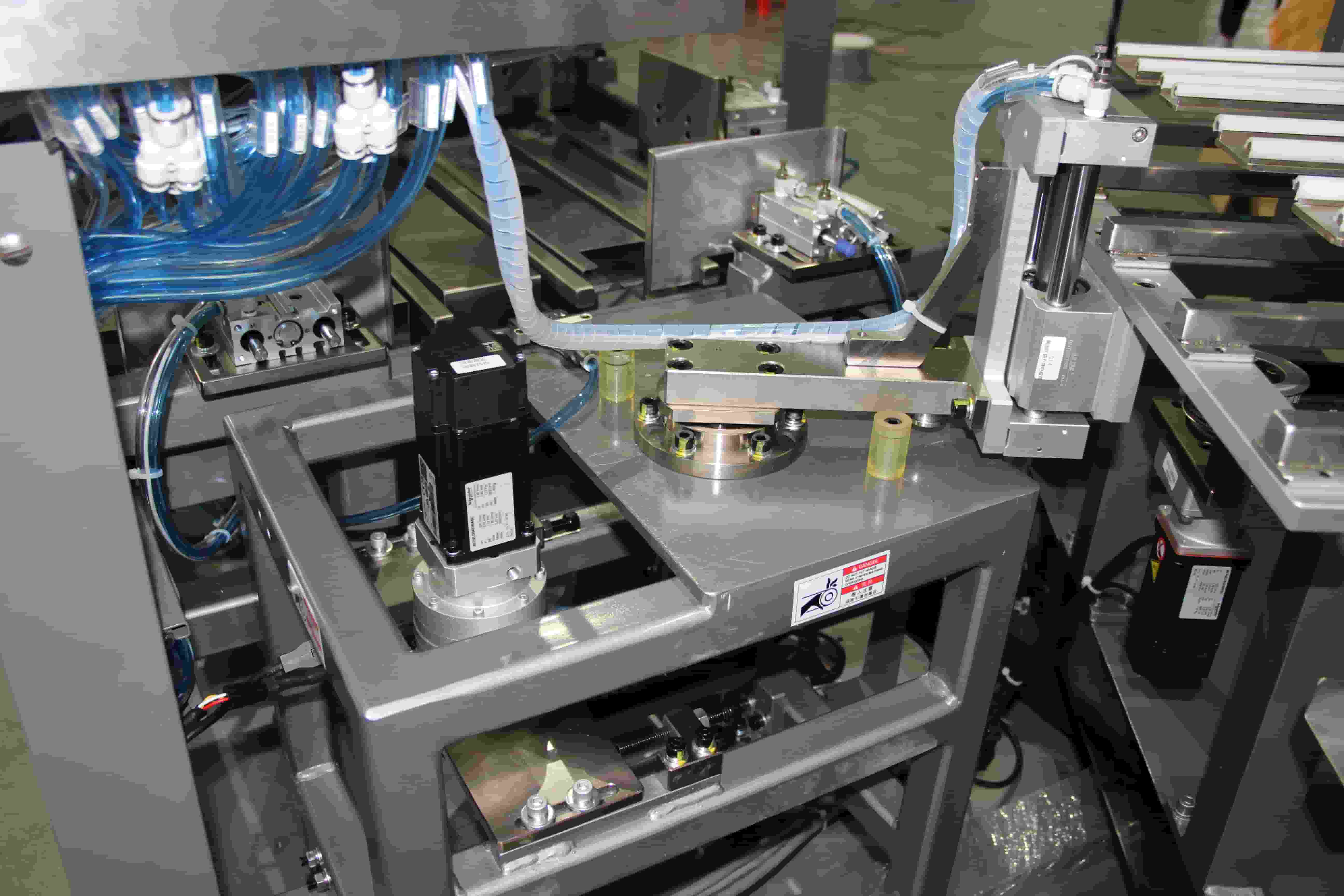

1. Intelligent bag insertion system

· Six-axis robotic arm + visual positioning system to achieve ±1mm precise bag insertion

· Adaptive pressure adjustment bag clamping device, compatible with 25-50kg bags of different specifications

· Double-station alternating operation to ensure continuous operation of the sack inserter machine

2. Injection and suction dust suppression system

· Multi-stage negative pressure dust removal device, dust collection efficiency > 99.8%

· Closed bag insertion cabin design, effectively controlling dust spillage

· Real-time dust concentration monitoring, automatic shutdown protection when exceeding the standard

3. Synchronous follow-up system

· Dynamically matching the rotation speed of the valve sack inserter machine, error < 0.05 seconds

· Servo-driven roller group realizes 0.1mm position control

· Three-level buffer bag storage warehouse design to ensure the continuity of bag supply

II. Technical parameter comparison

(Table)

II. Actual application results

Renovation case of a large cement group:

· Bag insertion success rate: stable at more than 99.9%

· Hourly output increased: from 90t/h to 120t/h

· Annual labor cost savings: more than 1.2 million yuan

· Dust emission reduction: from 18mg/m³ to 4.2mg/m³

· Automatic sack inserter machine failure rate reduced: maintenance frequency reduced by 70%

IV. System composition

Intelligent bag conveying module

· Bag storage warehouse capacity: 200-300 Bags

·Bag sorting device: automatically completes bag opening orientation

·Servo bag conveyor roller: adjustable speed 0-20m/min

Six-axis bag insertion robot

·Load capacity: 5kg

·Repeat positioning accuracy: ±0.05mm

·Working radius: 1.2m

Dust control system

·Filter area: 60㎡

·Handled air volume: 12000m³/h

·Emission concentration: <5mg/m³

Intelligent control system

·Industrial-grade PLC+12-inch human-machine interface

·Support MES system data docking

·Fault self-diagnosis and remote operation and maintenance

(Bag insertion video)

V. Industry value

1. Occupational health: realize zero contact with dust at the operating position

2. Technology upgrade: support intelligent transformation of packaging lines