GACHN GROUP OD108mm Micro Perforation Needle Roller is for the Plastic and Textile Industry, offering precise and durable perforating roller performance. It is ideal for professionals who require high-quality perforation for their respective fields.

Product name :

Micro Perforation Needle RollerPayment :

According to actual needsProduct Origin :

CHINAShipping Port :

Xiamen PortLead Time :

To be negotiated base on the quantityPRODUCT DETAIL

OD108mm Micro Perforation Needle Roller

High Density Perforating roller for maximum performance. Our Needles were made from high corbon steel with precise grinding and other processing.

Our needle roller adopts imported alloy steel wire, wear-resistant and durable: The tip flatness ≤0.06mm, uniform and stable air permeability. Needle body is made of hard copper alloy. The punching density is up to 160 pins/cm².

We offer the needle roller for block bottom woven bags and so on.

Our company can provide perforation roller and perforation unit according to customer's request.

We offer all the types of Perforating rollers for cement bag manufacturing machines from Starlinger, W&H, Lohia etc.

Needle Roller for valve bag making machine dealer

FEATURES

Professional Micro Perforation Needle:

1.Our Micro Perforation Needle is for the Plastic and Textile Industry, offering precise and durable perforating roller performance. It is ideal for professionals who require high-quality perforation for their respective fields.

2.Customized Solutions: Our Micro Perforation Needle is offered with OEM and ODM customization options, allowing for tailored solutions to meet your specific needs and preferences in the industry.

3.Grade-A Industrial Grade: This product is designed to meet the demanding requirements of the industrial sector, ensuring a high level of performance and reliability in harsh environments. It is built to withstand the rigors of daily use and withstand the test of time.

4.Industry-Specific Keywords: Our Micro Perforation Needle, as a professional perforating roller for both the Plastic and Textile Industries, is tailored to meet the unique needs of these sectors. It boasts the perfect combination of precision, durability, and versatility, making it an indispensable tool for professionals working in the industry.

APPLICATION

Perforating roller is used for Plastic films, aluminium foils, leathers, artificial leathers, textiles, non-wovens, papers, etc.

Types of laminated woven sacks where perforation is widely used.

-Block bottom bag

-Regular Woven Sacks

-Woven mesh film bags

-Side gusstet and pinch bottom woven sacks

-One or two ply flat and side gusseted tubesfrom plastic films,

-Woven fabric and composite materials

-PP woven fabric sacks

-ADStar woven bags

-AD Pro Tex woven bags

-Blockmatic woven bags

Needle Roller for Valve sack making machine intelligent equipment

SPECIFICATION

| Needle Diameter | According to customers' requirements,the minimum diameter is 0.25mm |

| Angle of Inclination | 90°,85°,80°,75°,70°,65°,60°,55°,50°,45° |

| Needle Density | Up to 160 pins/cm² |

| Drill Depth | Max 8mm |

| Hole Pattern | Almost any pattern is possible,linear,spiral-patterns according to the demand |

| Diameter of Roller | 10~350 mm |

| Height of Roller | Max 300mm |

| Roller Material | Bronze,brass,aluminium |

| Concentricity | High concentricity (0.07mm) |

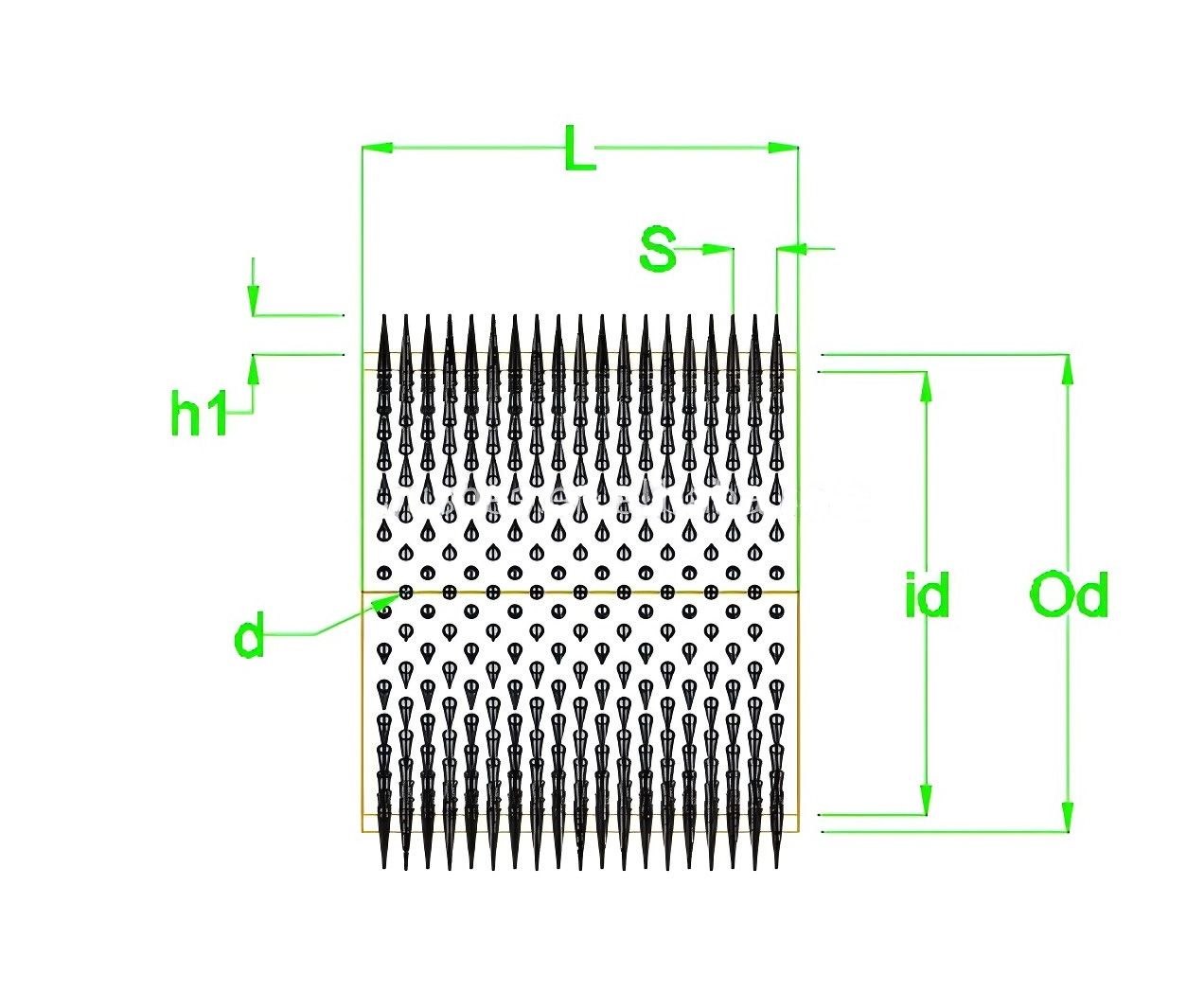

| L | S | id | Od | d | h1 |

| Roller Length | Needle Space | Core Inner Diameter | Core Outter Diameter | Needle Diameter | Needle Height |

WHY CHOOSE US

The steel needle is tight ,does not fall off, and the impressionis uniform. The imported machine punches holes.

Strictly control the production process ofproducts ,carefully do a good job, and eachproduct is made with ingenuityonly for quality products.

It is easy to use and widely used. It can work under high or lowtemperature for a long time, with excellent insulation performance.

FAQ

Q1:Are you a factory or a trading company?

A1:we are a smart packaging machine factory.

Q2:What product you produce?

A2:Block bottom valve sack making machine, bag inserter machine and loading machine.

Q3:How can we guarantee quality?

A3:Always apre production sample before mass production.

Always final Inspection before shipment;

Q4: Where is your factory located? How can I visit there?

A4: Our factory is located in Xiamen city, Fujian Province, China. All our clients,from home or abroad, are warmly welcome to visit us!

Q5: What about your main market?

A5: Our products be sold well in 30 provinces and have good reputation in China, also we pay attention on developing theoverseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. Shine East people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed lSO.