Factory Tour

Factory Tour

Workshops

The first and second floors of GACHN group are assembly workshops where workers process, assemble, test and adjust products with various equipment and tools to ensure quality control. The assembly workshops usually have lighting, ventilation, material transport and safety conditions and measures for higher production efficiency and better worker safety.

We produce equipment here for various industries that GACHN Group is involved in : paper sanitary products, cosmetic products, lithium batteries,cement bags and cement packaging, wind power generation, can packaging and food.

Manufacturing & Measuring

GACHN group has an advanced and large manufacturing & measuring center to underpin automatic production and precision.

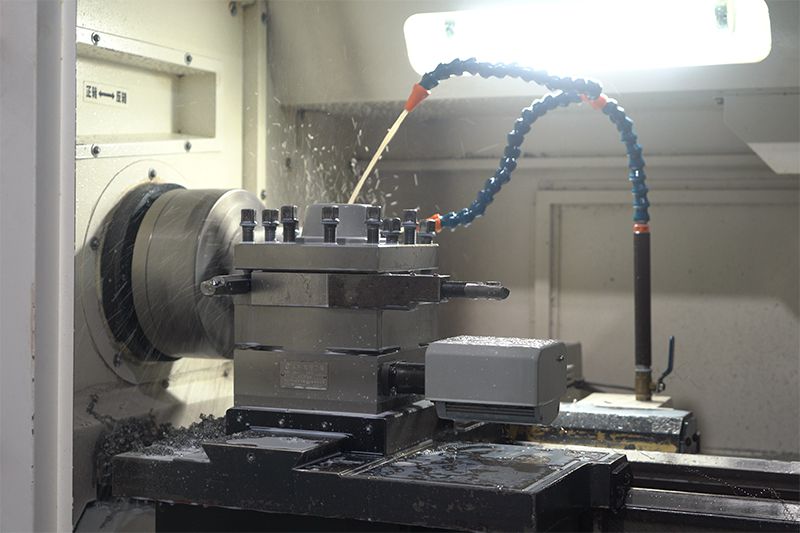

CNC Processing Center for precise processing of sophisticated components

CNC machine tool is an automatic machine tool with high precision and efficiency. Equipped with turrets, the machine tool can process a wide spectrum of complicated components and has a good performance in mass production of those parts.

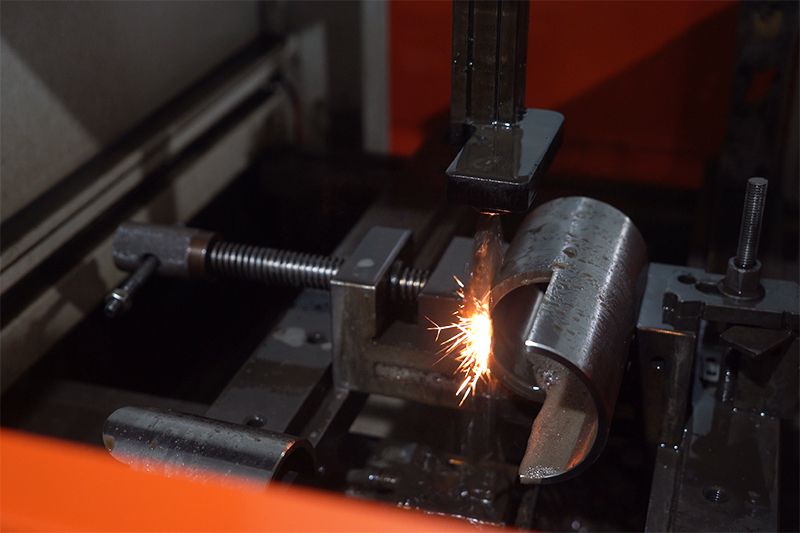

--

Wire-Cut Electrical Discharge Machining (WEDM) is an electro thermal production process in which a thin metallic wire cuts through metal by the use of heat from electrical sparks.

Quality Control & Warehouse

Quality control area is where our product quality will be tested to ensure it meets related standards and requirements. Our company will test machines and parts respectively before delivery and, in particular, provide quality reports of static tests and operation tests. Qualified products will be put in the warehouse or delivered for further production.