Development History of PP Plastic Woven Square Bottom Valve Bag Making Machine

PP Plastic Woven Square Bottom Valve Bag Making Machine (usually referred to as AD*STAR bag making machine) is a kind of equipment used to produce coated polypropylene (PP) woven bags, especially for producing high-performance composite bags (such as cement bags, fertilizer bags, etc.). Its development history can be traced back to the innovation of multiple technologies and the promotion of industry needs. The following is a summary of the development history of PP Plastic Woven Square Bottom Valve Bag Making Machine:

1. Technical Background and Start-up

PP Plastic Woven Square Bottom Valve Bag Making Machine was originally developed by the Austrian company Starlinger in the early 1980s. The Austrian company Starlinger is a manufacturer focusing on plastic industrial machinery and is committed to developing innovative technologies for the packaging industry.

At that time, plastic woven bags gradually replaced traditional paper bags and sacks and were widely used in the packaging industry, especially in the packaging of cement and other granular materials. Although traditional plastic woven bags have strong load-bearing capacity, they lack waterproof and moisture-proof functions, which is an important problem for some industries, especially the cement industry.

2. The birth of woven square bottom valve bag production technology

The key innovation of woven square bottom valve bag production technology lies in its composite structure, which can combine non-woven fabrics with polypropylene woven bags, thus solving the problem of poor moisture resistance of simple woven bags. In the late 1980s, the Austrian company Starlinger launched a woven square bottom valve bag manufacturing machine, which can produce a new type of bag-AD STAR composite bag (woven square bottom valve bag).

The characteristics of this composite bag are:

• High strength: It has high tensile strength and durability, suitable for packaging heavy objects.

• Moisture-proof and waterproof: The composite structure of the outer layer coating enhances the moisture resistance of the bag.

• Environmental protection: The woven square bottom valve bag has good recyclability and meets the increasingly stringent environmental protection requirements at that time.

3. Further technical innovation and improvement

The woven square bottom valve bag making machine has undergone continuous optimization in technology:

♦ Improved automation: The early square bottom valve bag making machine required more manual intervention, but with the advancement of technology, the equipment gradually realized more automated operations, including automatic cutting, automatic sewing and other functions, which improved production efficiency.

♦ Multi-layer bag body: Woven square bottom valve bag can further enhance the strength and protection performance through multi-layer composite materials, while reducing the thickness of the bag, thereby reducing material costs.

♦ Environmentally friendly material application: With the continuous improvement of environmental protection requirements, woven square bottom valve bag making machines are gradually adopting more environmentally friendly raw materials, such as biodegradable plastics.

4. Research and development of GACHN-JEENAR woven square bottom valve bag making machine

With the increasing demand for woven square bottom valve bags in the domestic market, GACHN JEENAR officially launched the research and development project of woven square bottom valve bag making machine in 2017, and successfully developed and launched it to the market in 2021. GACHN-JEENAR woven square bottom valve bag making machine has successfully avoided more than 20 foreign patents, especially 3 important invention patents, and is completely independently developed without the risk of patent litigation. Once launched, GACHN-JEENAR's bag making machine quickly gained recognition from customers and received praise from domestic and foreign customers.

♥ Comparison of machine performance with European equipment

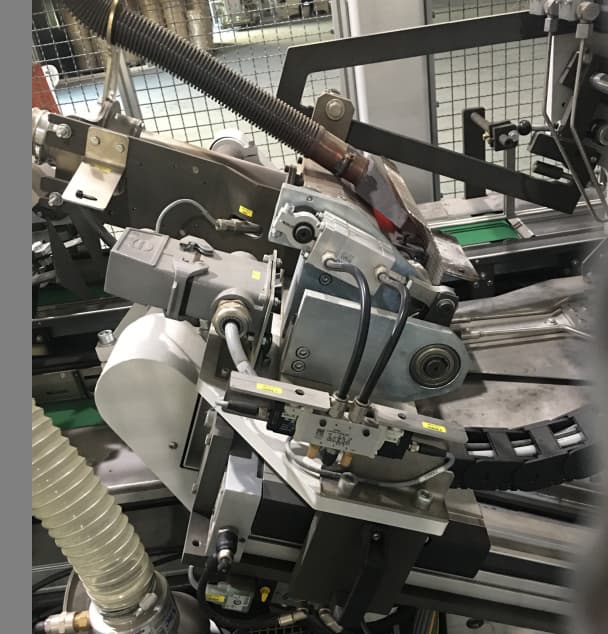

◊ Bag opening mechanism

VS

VS

Our equipment European equipment

The bag opening mechanism used in our equipment is the company's unique patent, using an innovative bag opening process, the use of negative pressure and the multi-step combination of the conveying system, to achieve high efficiency, stability, low maintenance, to help customers get the maximum value. Independent research and development, with independent core technology and intellectual property rights, no litigation risk of infringement of intellectual property rights. The internationally renowned brand equipment is the suction cup opening bag, the suction cup life is short, need to be replaced frequently; The mechanism adopts reciprocating movement mode. Under the condition of high speed movement, the mechanism has jitters and other uneasiness factors, which is easy to cause the failure of opening the bag.

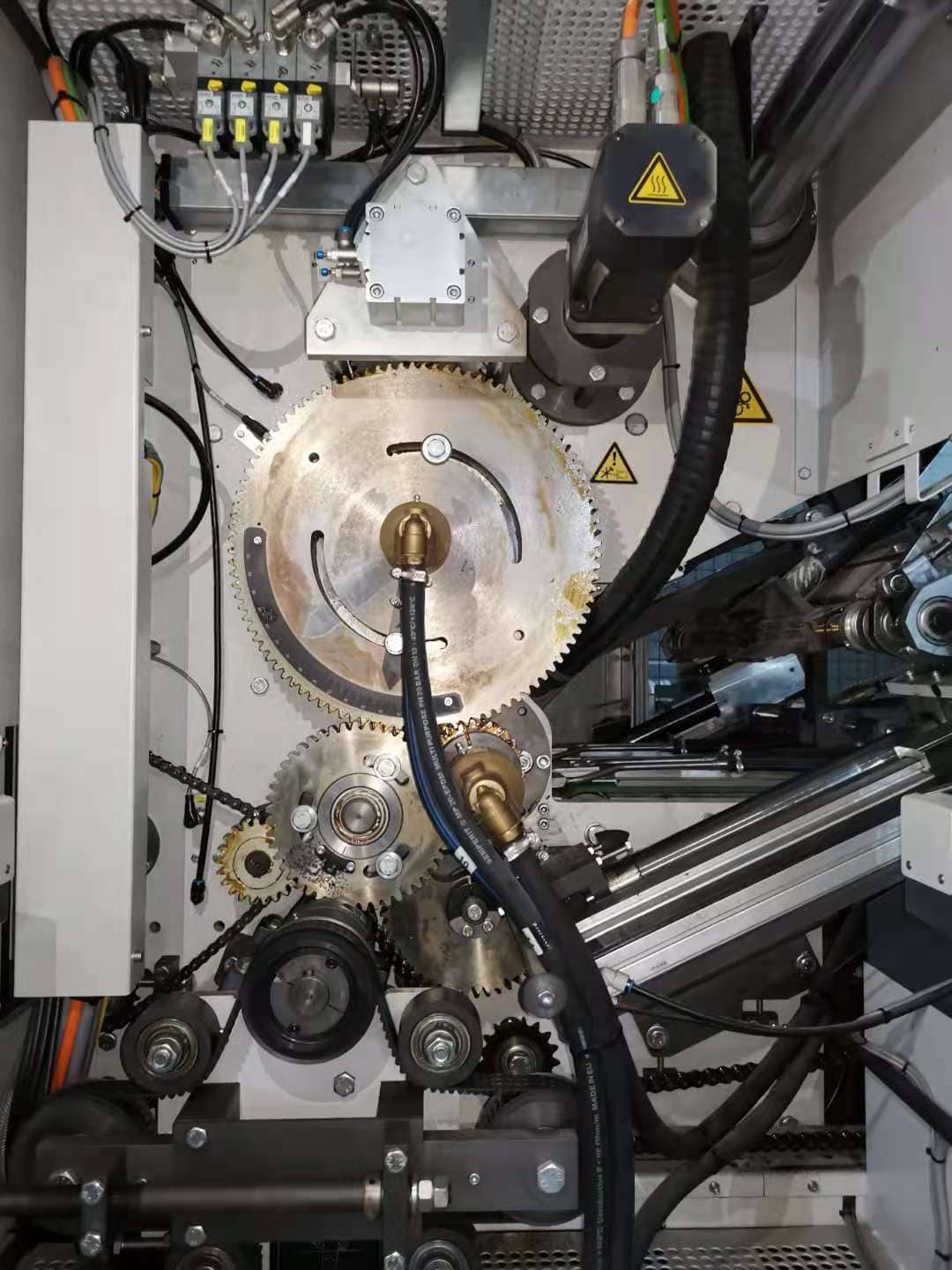

◊ 3 sets of Heat sealing mechanism

vs

vs

Our equipment European equipment

Our equipment adopts professionally designed heat sealing welding system, using unique technology to achieve uniform wind and constant size. Servo control of the wind commutator axis switching, precise control of welding on and off time, welding quality is higher. The width of the mouthpiece is adjustable, and the welding width can be controlled flexibly. The cylinder mechanism is used in internationally renowned brand equipment to control the blowing switching action. The movement time of the cylinder is easily affected by factors such as the sticking caused by the wear of spare parts and the change of the air pressure of the air compressor, thus affecting the welding position. The width of the mouthpiece is adjusted by replacing the width block, each 5mm is a unit, and the replacement and size adjustment are not flexible.

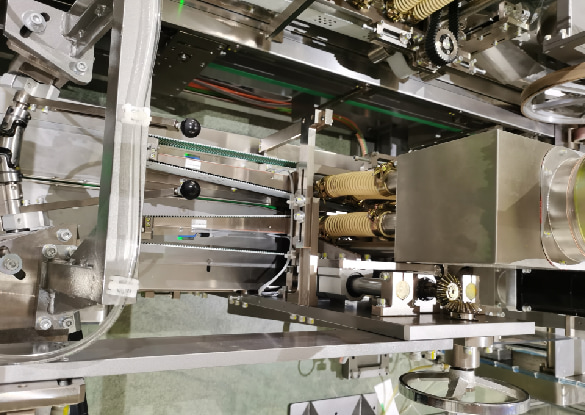

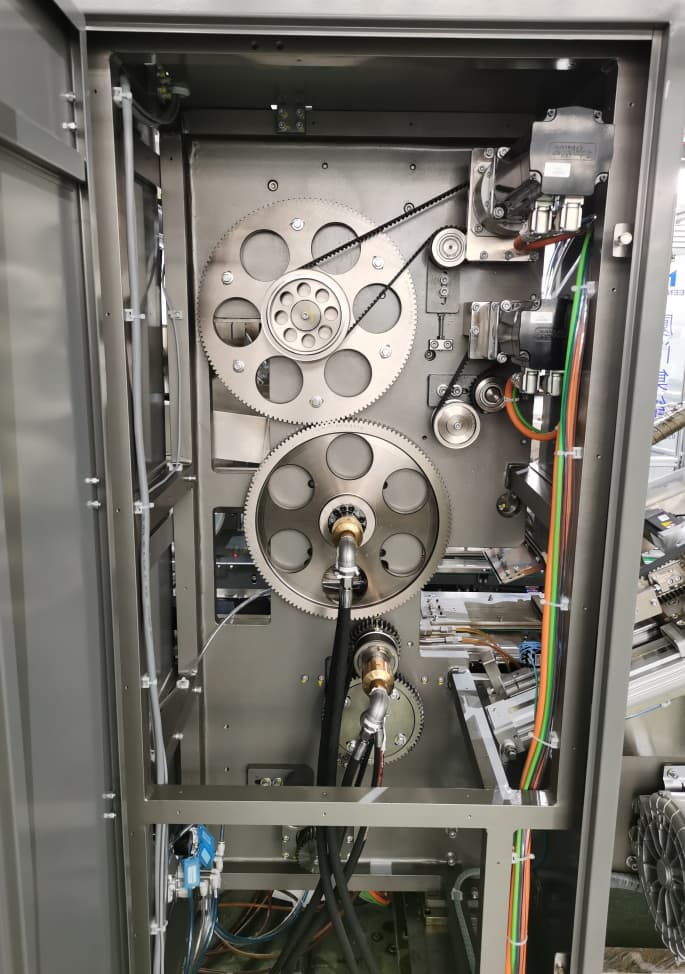

◊ 3 sets of heat-seald knife roller and adsorption roller mechanisms

vs

vs

Our equipment European equipment

The 3 sets of heat-sealed knife roller and adsorption roller mechanisms on our equipment are all independently controlled by servo motors, and the file number of corresponding parameters is directly transferred when the number is changed to achieve rapid number change. The position before and after welding of valve paste and bottom paste material can be manually adjusted online; Foreign equipment adopts the working mode of mechanical gear linkage. When replacing specifications, it is necessary to loosen the screws on the gear, adjust the Angle, which is inconvenient to operate and troublesome to change the number and adjust.

Those above are some details about the advantages of our equipment, hope this can help you avoid the worry of purchasing our equipment. I am sure you will make the smart choice to secure the future prosperity of your business.