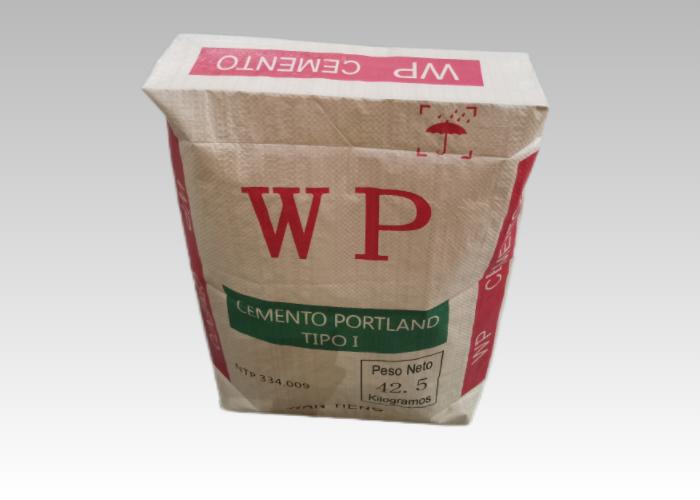

25KG 50KG PP Woven Block Bottom Valve Cement Putty Powder Bag Flour Bag

GACHN JEENAR High quality Empty BOPP laminated 20kg 25kg 40kg Plastic PP woven bag for wall putty powder packing sack 50kg

Product name :

25kg 50kg pp woven block bottom valve cement putty powder bag flour bagProduct Origin :

ChinaSurface Handling :

shape embossing, anti-skidding, easy to stow and transport.Material Structure :

PP or PP+PE+BOPPAppearance :

glossy/matt lamination, anti-UV coated,antiskid,breathable, Anti-slipMoistureproof :

Laminated PE or PP, inside or outside (14gsm-30gsm)Characteristics :

moisture-proof, tightness, highly tensile, tear resistant25kg 50kg pp woven block bottom valve cement putty powder bag flour bag

| Specification | |

| Name | BOPP laminated PP woven sack bags |

| Load weight | 5kg to 100kg |

| Material | 100% original pp |

| Shape | tubular |

| length | 300mm to 1200mm |

| width | 280mm to 750mm |

| Characteristics | moisture-proof, tightness, highly tensile, tear resistant |

| Application | Packing for food, agriculture products, chemical, fertilizer, construciton |

| Fabric treatment | Breathable, anti-slip, UV-Stabilization, laminated, inner or outside coated |

| Inside liner | PE laminated inner or not |

| Printing | Gravure printing, flexo printing, BOPP printing, one side or both sides |

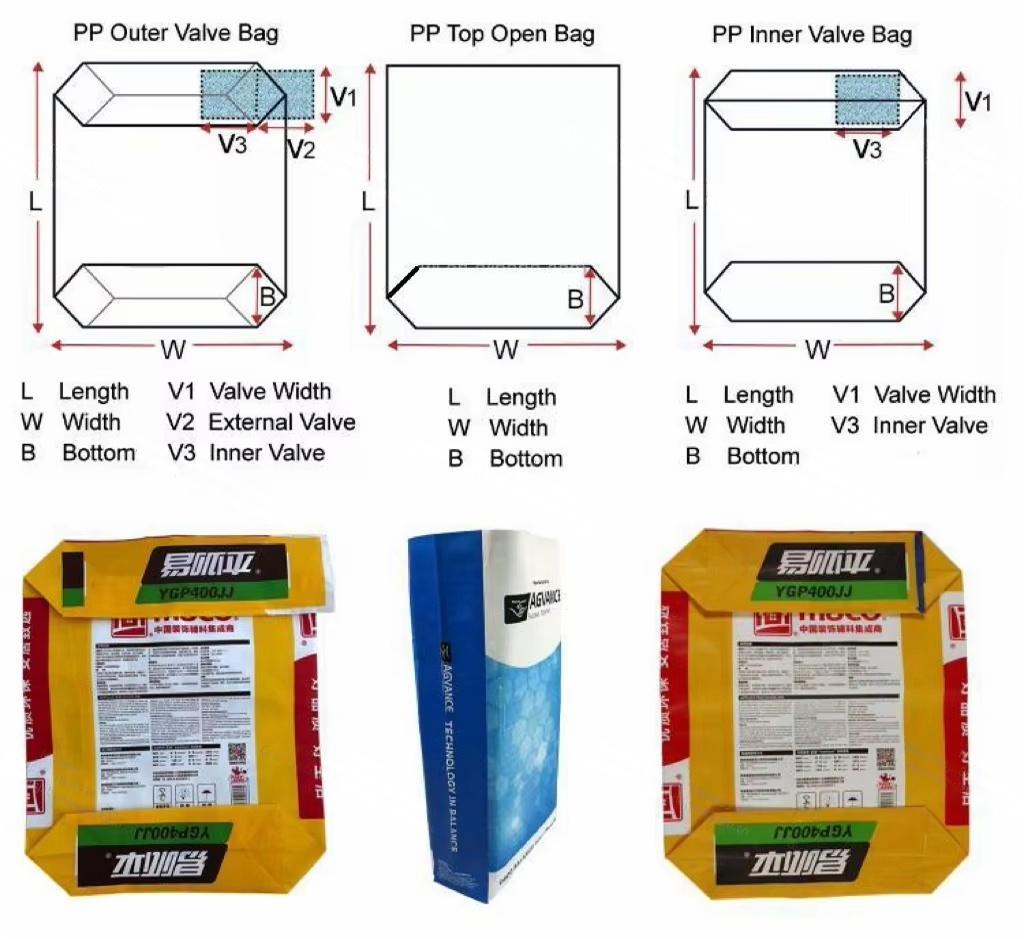

| Side | plain, gusset M side |

| Top | heat seal, hemmed, pouch hole, plastic handle |

| Bottom | single stitched, double stitched, block bottom, easy open |

| Optional choice | Inner laminated, side gusset, back seamed, valve filling |

| Package | about 500pcs for one bale or 5000pcs one wooden pallet |

| Delivery Time | within 25-30 days for one 40H container |

WE HAVE COMPLETE EQUIPMENT FOR QUALITY,We are pp woven block bottom valve sack making machine Producer

01 block bottom valve bag

In recent years, our company has introduced a series of advanced equipment including (Ad.Starlinger extruders, circular looms, Ad.Starlinger laminating and back sealing machines, Ad.Starlinger block bottom valve bag machine). In addition, we have obtained lS09001,certifcates

02 Product details

Meanwhile, we have complete equipment for quality testing so that we can ensure that the quality of products is strictly in accordance with theclients' requirements.In 2005, our products passed the evaluation of lS09001 certification.

03 Bag

"Customer first and reputation first" is the tenet wealways adhere to. High quality. competitive price and superior service help us win honorand clients' trust.

One of the latest trends in the packaging industry is the use of Bi-axially Oriented Polypropylene (BOPP) Laminated PP Woven Bags, also known as BOPP bags. These bags boast superior photographic appearance and better weather resistance, increasing the shelf life of packaged products. BOPP bags have become one of the most popular packaging materials due to their durability.

BOPP bags are woven and laminated with organic materials during the manufacturing process, making them extremely durable and resilient. Unlike plain woven bags, BOPP bags print out exceptionally well and hold up better in the printing and laminating process.

Strict Quality Control

As a professional manufacturer of the Polypropylene woven packaging bag, we make our bags:

1. In 100% virgin raw material

2. Eco-friendly ink with good fastness and bright colors.

3. Top grade machine to ensure a strong break-resistance, peel-resistance, stable hot air welding bag,

ensuring the utmost protection of your materials.

4. From tape extruding to fabric weaving to laminating and printing, to the final bag making, we have strict

inspection and testing to make sure a high-quality and durable bag for end users.

Usage

Packing / transporting / storage

1. Food Area: sugar, salt, flour, starch.

2. Agriculture Area: grains, rice, wheat, corn, seeds, flour, coffee Beans, soybeans,potato

3. Feed: pet food, pet litter, bird seed, grass seed, animal feed( dog cat etc ).

4. Chemicals: fertilizer, chemical materials, plastic resin.

5. Construction material:sand, cement , powder

Why Choose Us

Our Service

1. We accept customized specifications and printing artwork.

2. We can make a design according to your requirements.

3. We promise to reply to your inquiry about product and price within 24 hours.

4. We can provide samples before mass production.

5. Good after-sale service offered.

6. We can ensure to make our business relationship confidential to any third party.

Our advantage:

1. We produce: export directly from the factory, advanced equipment from extrusion to packing, accept any custom order, quick delivery.

2. Good Service: “Customer first and reputation first” is the tenet we always adhere to .

3. Good Quality: strict quality control system, piece-by-piece inspection.

4. Competitive Price: low profit, seeking long-term cooperation.

5.We are pp woven block bottom valve sack making machine Wholesaler.